Transformer substation crane

A technology for substations and cranes, applied in cranes, transportation and packaging, etc., can solve the problems of poor stability of the crane mechanism and achieve the effect of good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

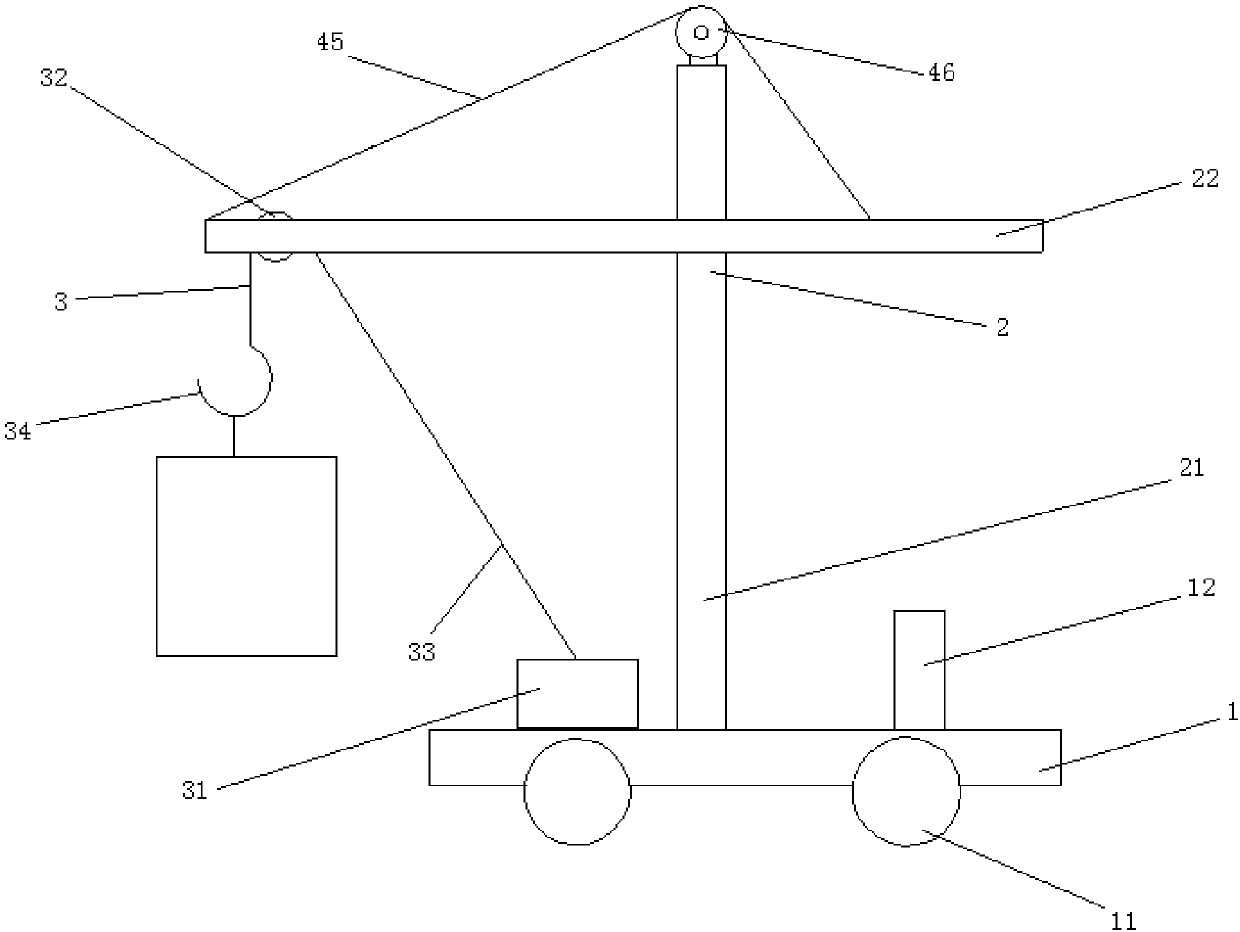

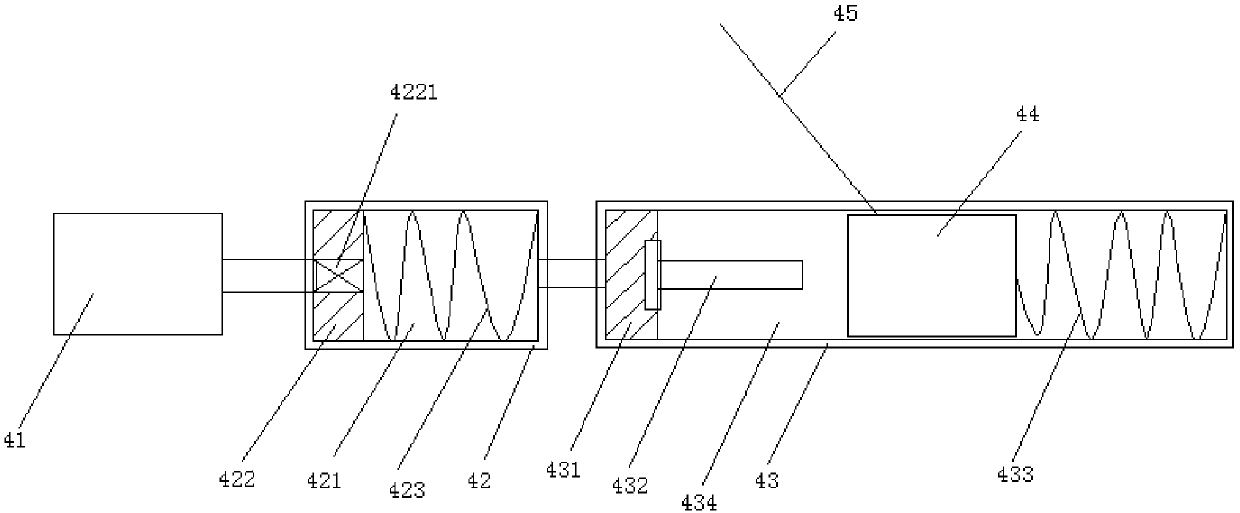

[0023] The reference signs in the accompanying drawings of the specification include:

[0024] Base 1, frame body 2, vertical support frame 21, transverse boom 22, lifting mechanism 3, motor 31, pulley 32, pull rope 33, hook 34, air pump 41, active cylinder 42, driven cylinder 43, active Cavity 421, active piston 422, one-way valve 4221, active compression spring 423, driven piston 431, driven piston rod 432, driven compression spring 433, driven cavity 434, counterweight slider 44, balance rope 45 , balance wheel 46, universal wheel 11, counterweight 12.

[0025] Such as figure 1 As shown, a substation crane includes a base 1, a frame body 2, and a lifting mechanism 3. Universal wheels 11 are installed under the base 1, and the substation crane can move freely in the substation site through the setting of the universal wheels 11. , to make it more flexible, and at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com