Sewing machine for making seams in a programmed, measured and controlled way

A sewing machine and sewing machine head technology, applied in the field of sewing machines, can solve problems such as imprecise seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

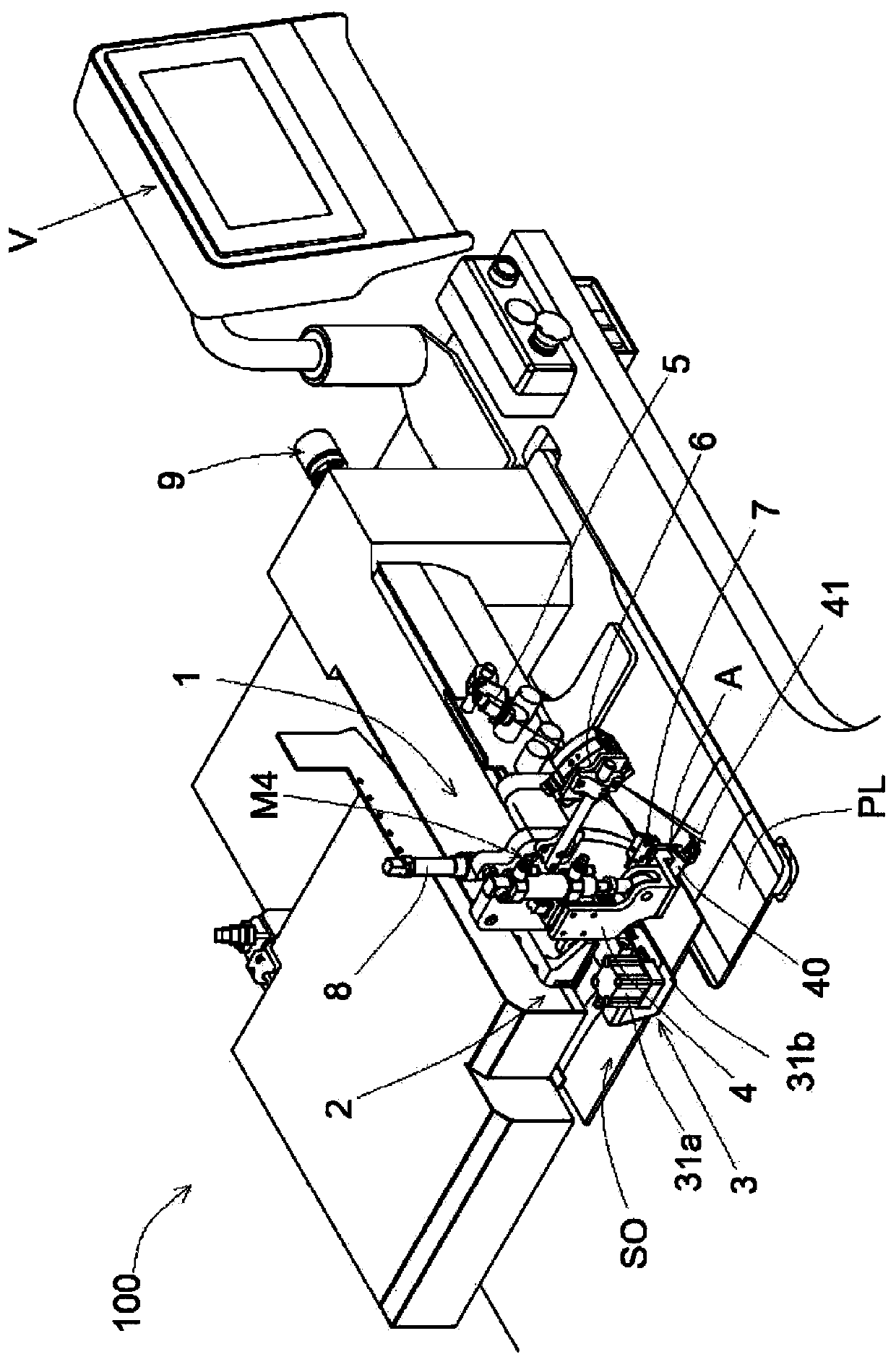

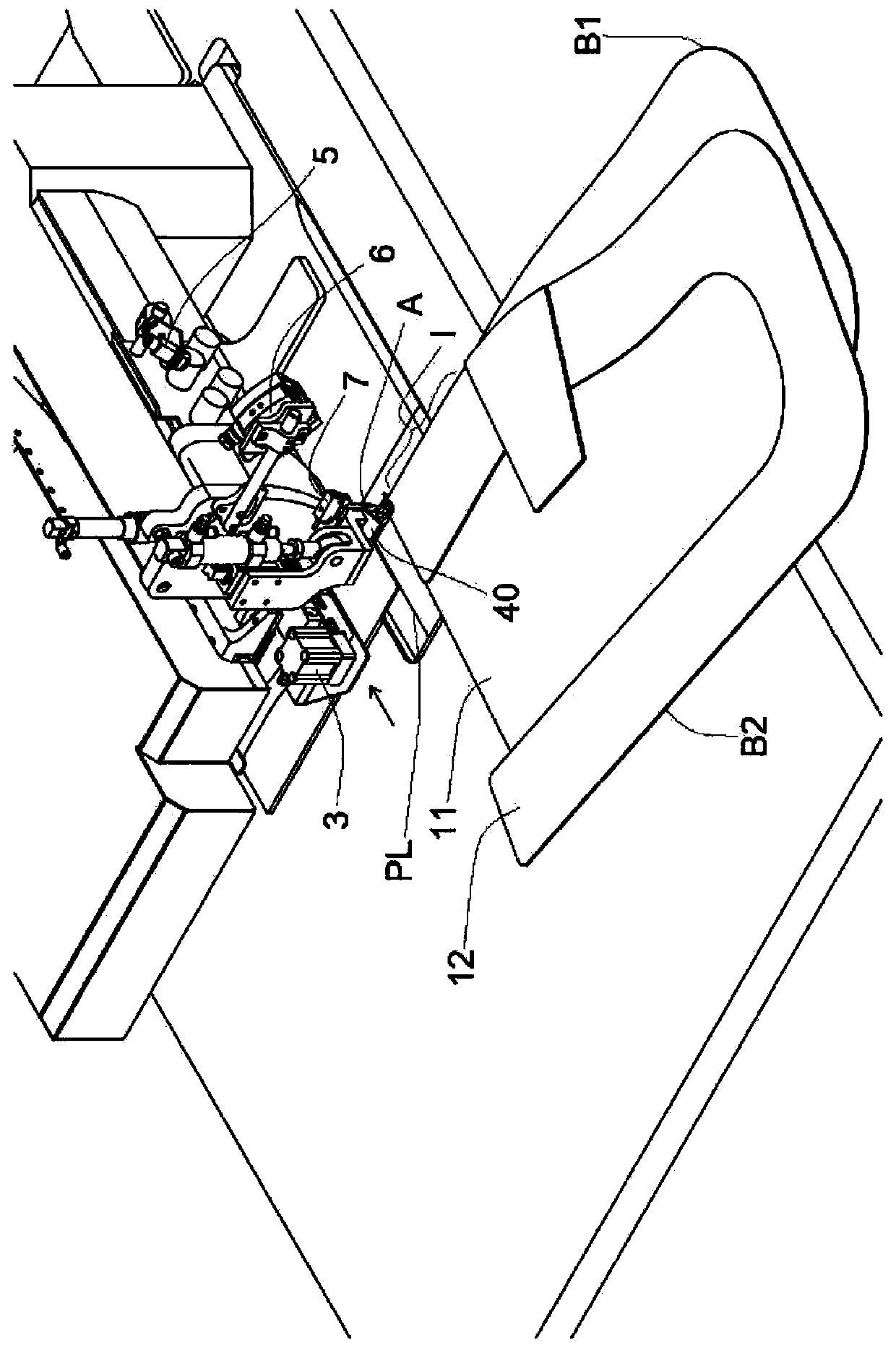

[0119] For this, refer to Figure 28 , Figure 29 and Figure 30 , according to a preferred embodiment of the present invention, the sewing machine 100 may have a detector R which is operatively connected to said control unit and which detects the two fabrics 11, 12, 13, 14 sewn by the needles A the length of a part. Specifically, the detector R detects the length between two adjacent stitches. According to one embodiment of the present invention, the detector R comprises:

[0120] - incremental encoder reader RE;

[0121] - a disk RD placed near the needle A, adapted to come into contact with the fabric 11, 12, 13, 14 in such a way that it rotates if the fabric moves along the working surface PL;

[0122] - the axis of rotation RA, which transmits the rotational movement of the disc RD to the incremental encoder reader RE;

[0123] - a device RV for activating / deactivating the detector R; in particular, the device RV places the detector R in a first position (wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com