Insulating property maintenance assistor for electric device

A technology of insulation performance and power devices, applied in the direction of switchgear, electrical components, chemical instruments and methods, etc., can solve problems such as limited scrubbing height, discounted wiping force of rags, and threats to eye safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

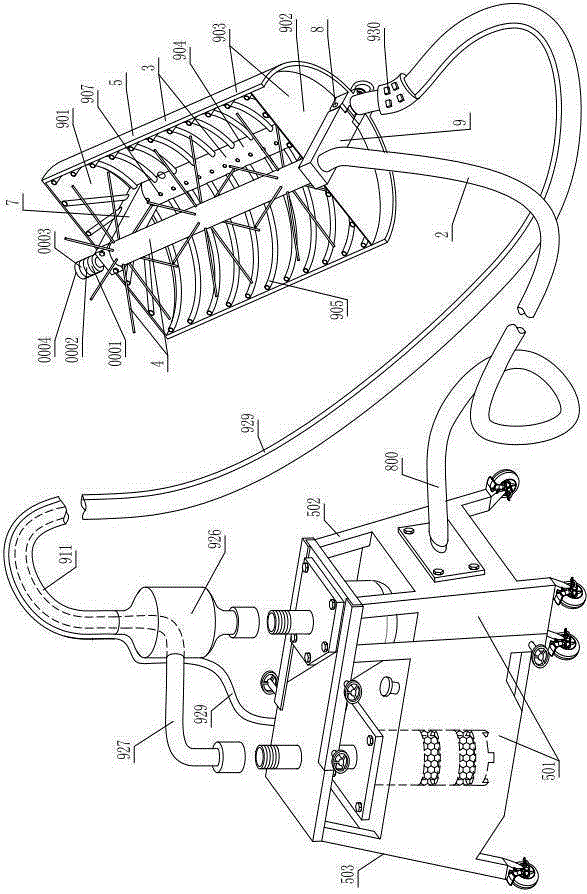

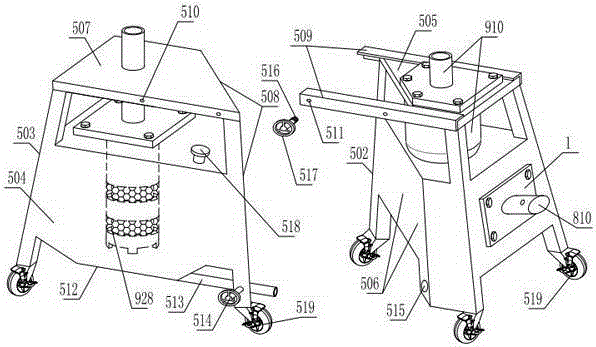

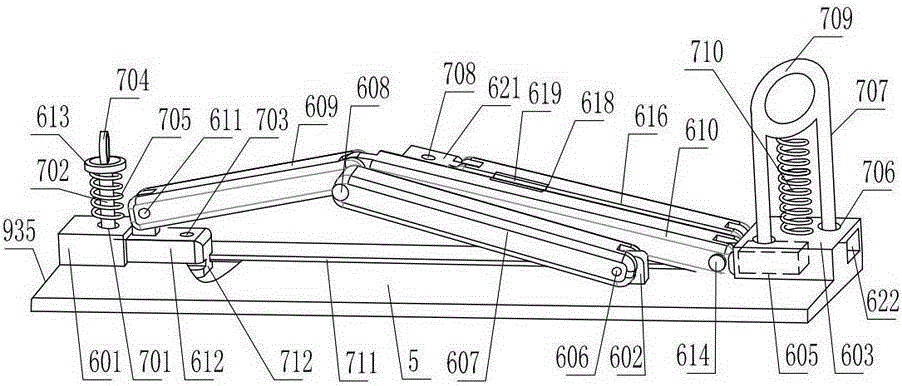

[0029] As shown in the figure, the auxiliary device for maintaining insulation performance of electric devices includes a cleaning head 3 driven by a power device 1 through a transmission hose 2. The cleaning head includes a vertically arranged rotating brush 4, and one side of the rotating brush is covered with a horizontal A protective cover 5 with a C-shaped cross-section, a handle 6 is fixed on the outside of the protective cover, and a horizontally extending upper rod 7 is fixed on the inner upper end of the protective cover. The end of the upper rod can only rotate with the upper end of the rotary brush through the upper connecting device. The lower end of the inner side of the cover is hinged with a lower rod 9 that can swing up and down through a horizontal shaft 8, and the lower rod is rotatably matched with the lower end of the rotating brush through the lower connecting device, and the lower rod is also inserted and matched with the lower end of the rotating brush thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com