Sewing machine

A technology of sewing machine and machine head, which is applied in the direction of sewing machine components, sewing machine needle holder, sewing machine thread take-up device, etc., can solve the problems of increasing cost, and achieve the effect of simple structure and restraining cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

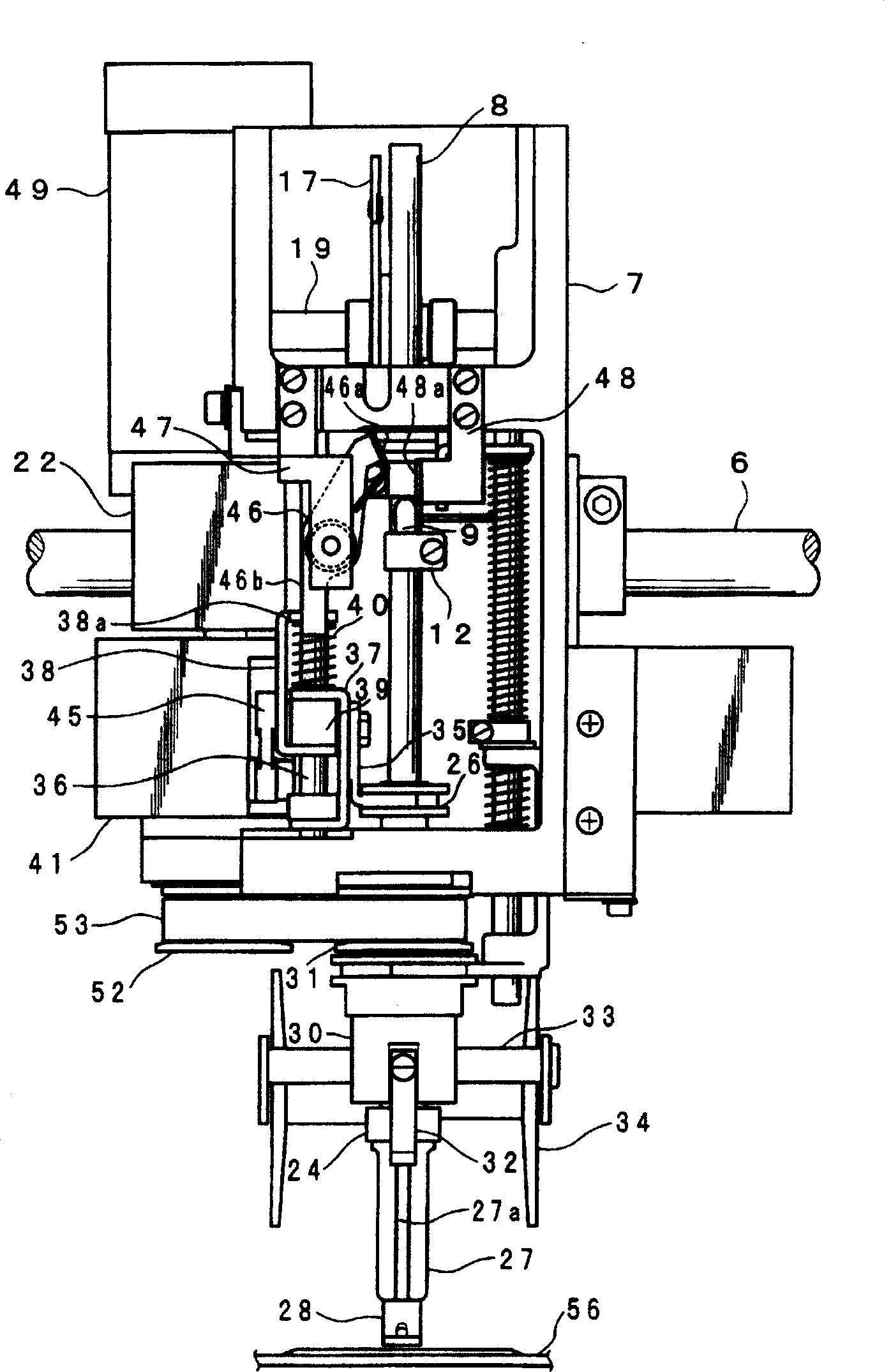

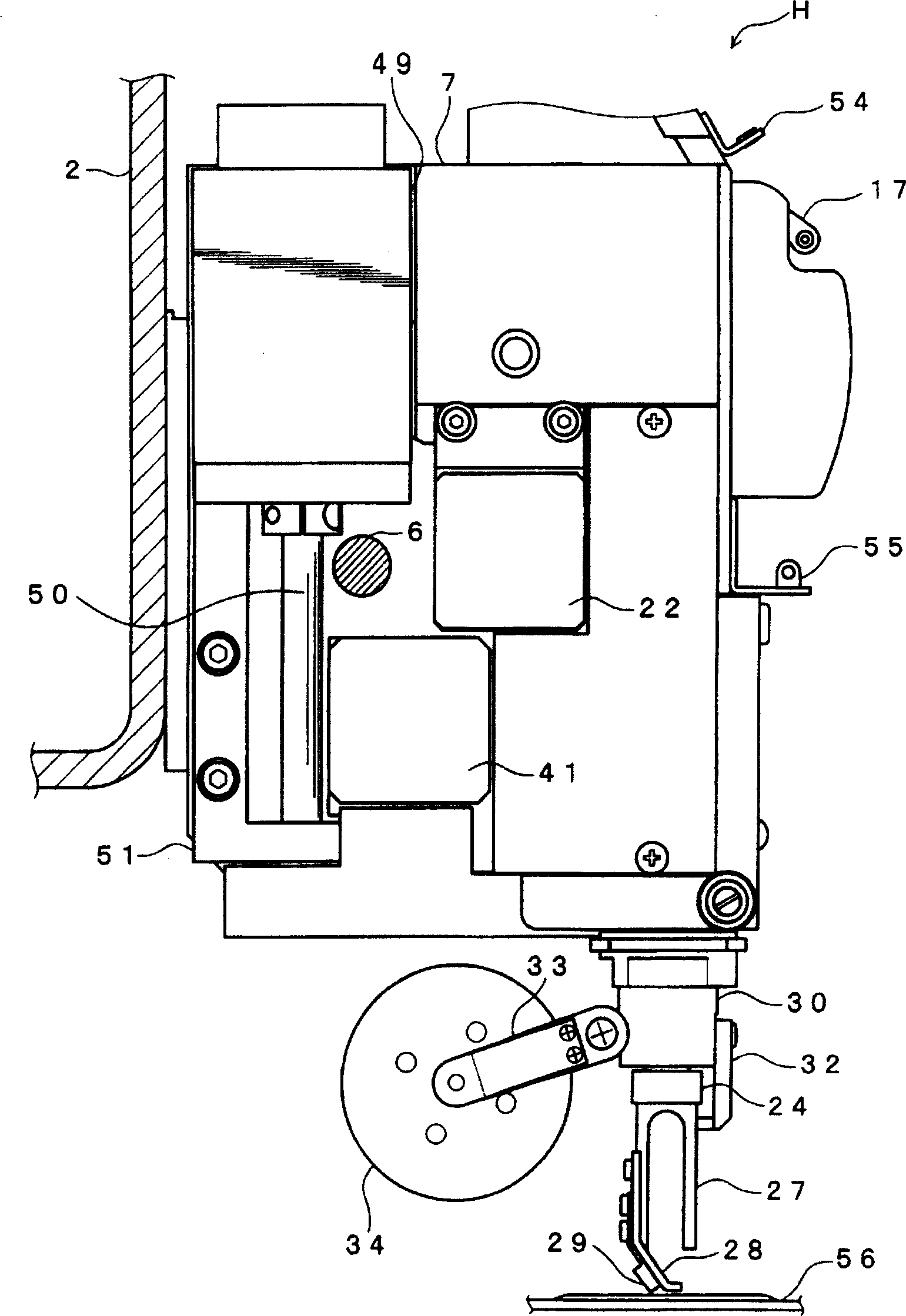

[0023] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

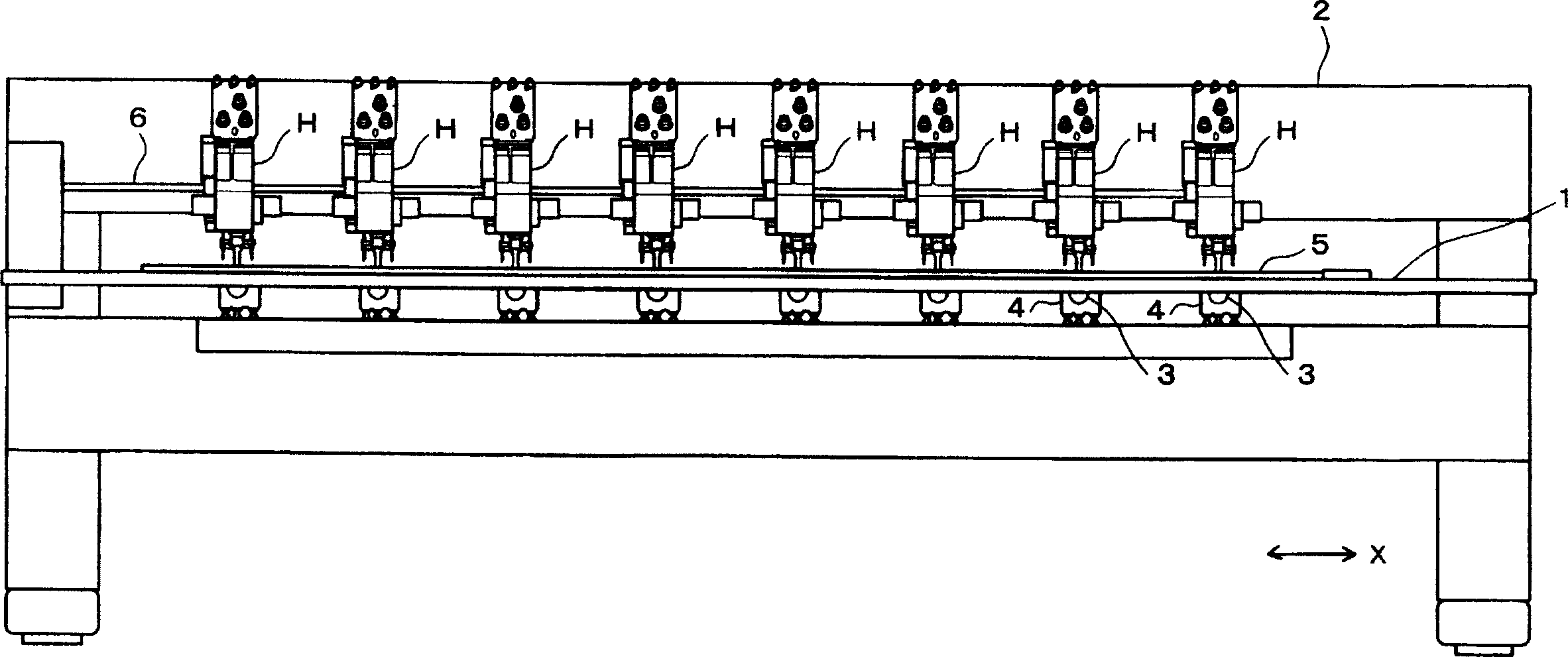

[0024] First, the outline of the multi-head sewing machine of the present invention will be briefly described. figure 1 It is a front appearance view showing an embodiment of the multi-head sewing machine of the present invention. This embodiment shows a multi-head sewing machine having a plurality (eight in the figure) of sewing machine heads H capable of sewing a string-like member. in addition figure 1 Among them, the front side corresponds to the front of the multi-head sewing machine at the actual position where the operator performs sewing work or the like.

[0025] figure 1 In the shown multi-head sewing machine, an upper frame 2 is disposed above an elongated sewing machine table 1 extending in the horizontal direction (X direction in the figure), and on the front surface of the upper frame 2, along the upper machine Sewing machine heads H ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com