Computer control system of industrial sewing machine

An industrial sewing machine and computer-controlled technology, applied in the direction of sewing machine control devices, sewing machine components, program-controlled sewing machines, etc., can solve problems such as difficulty in meeting the actual needs of users, lack of flexibility and scalability, and poor versatility of software and hardware platforms. Achieve the effect of friendly man-machine interface, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The industrial sewing machine computer control system of the present invention will be described in detail below in conjunction with the accompanying drawings.

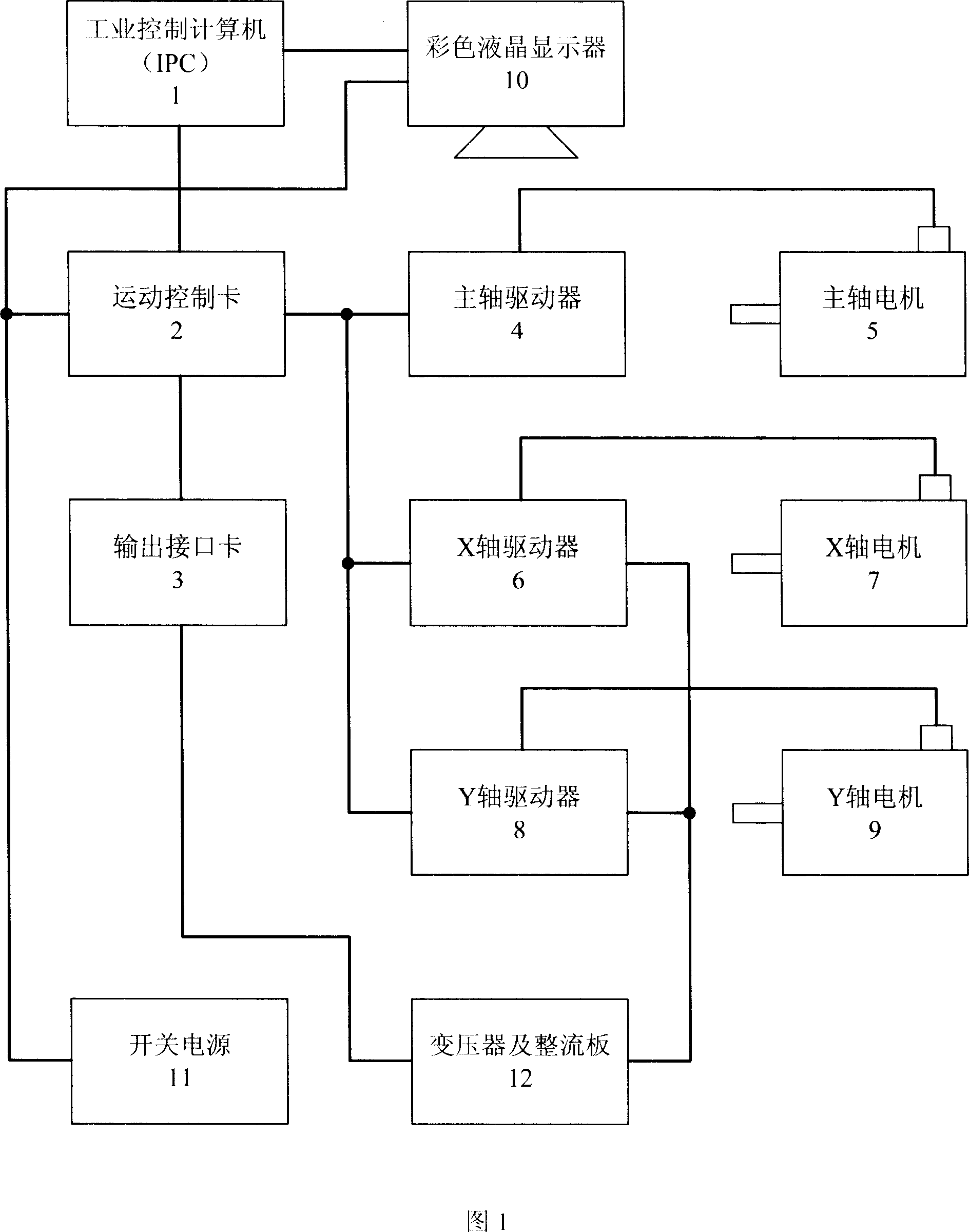

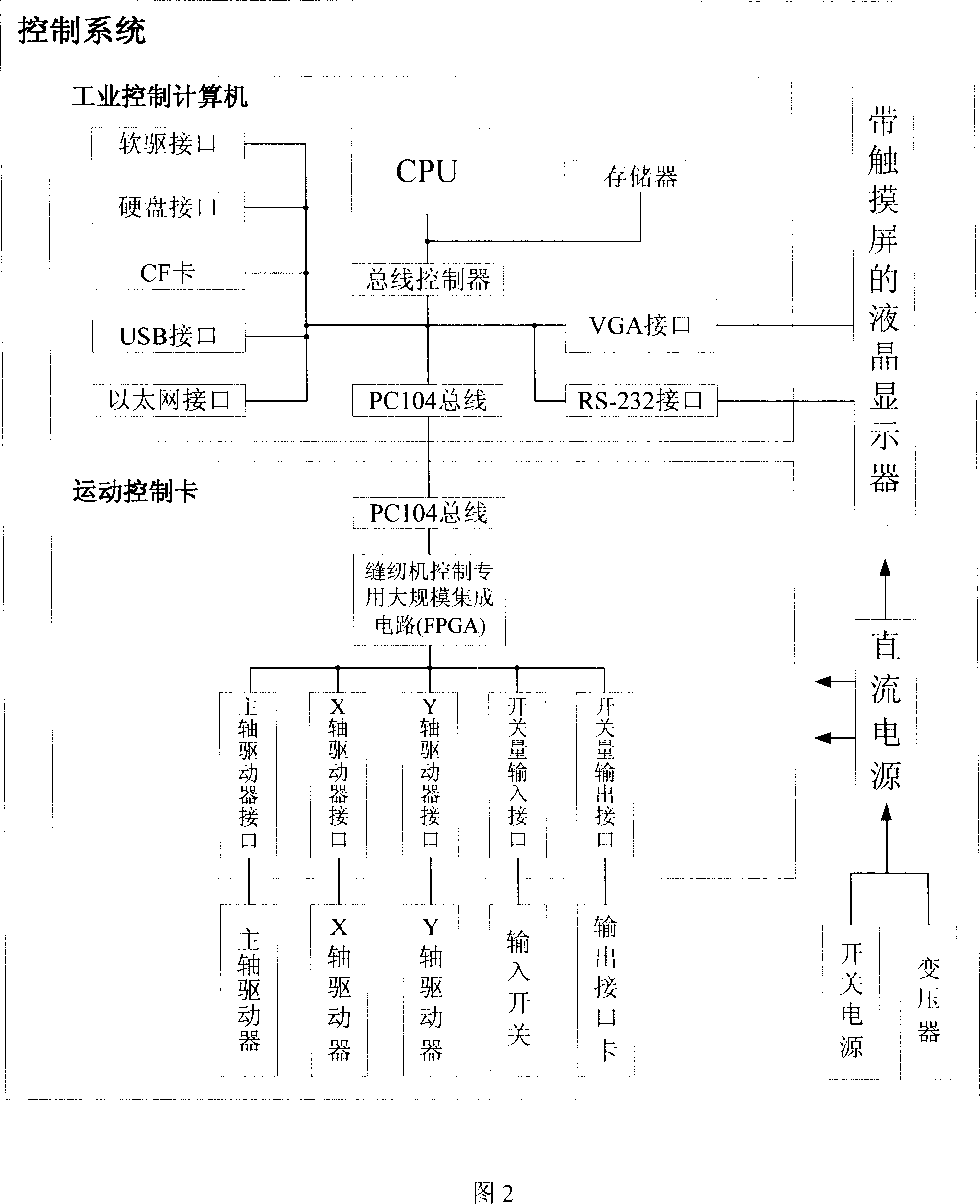

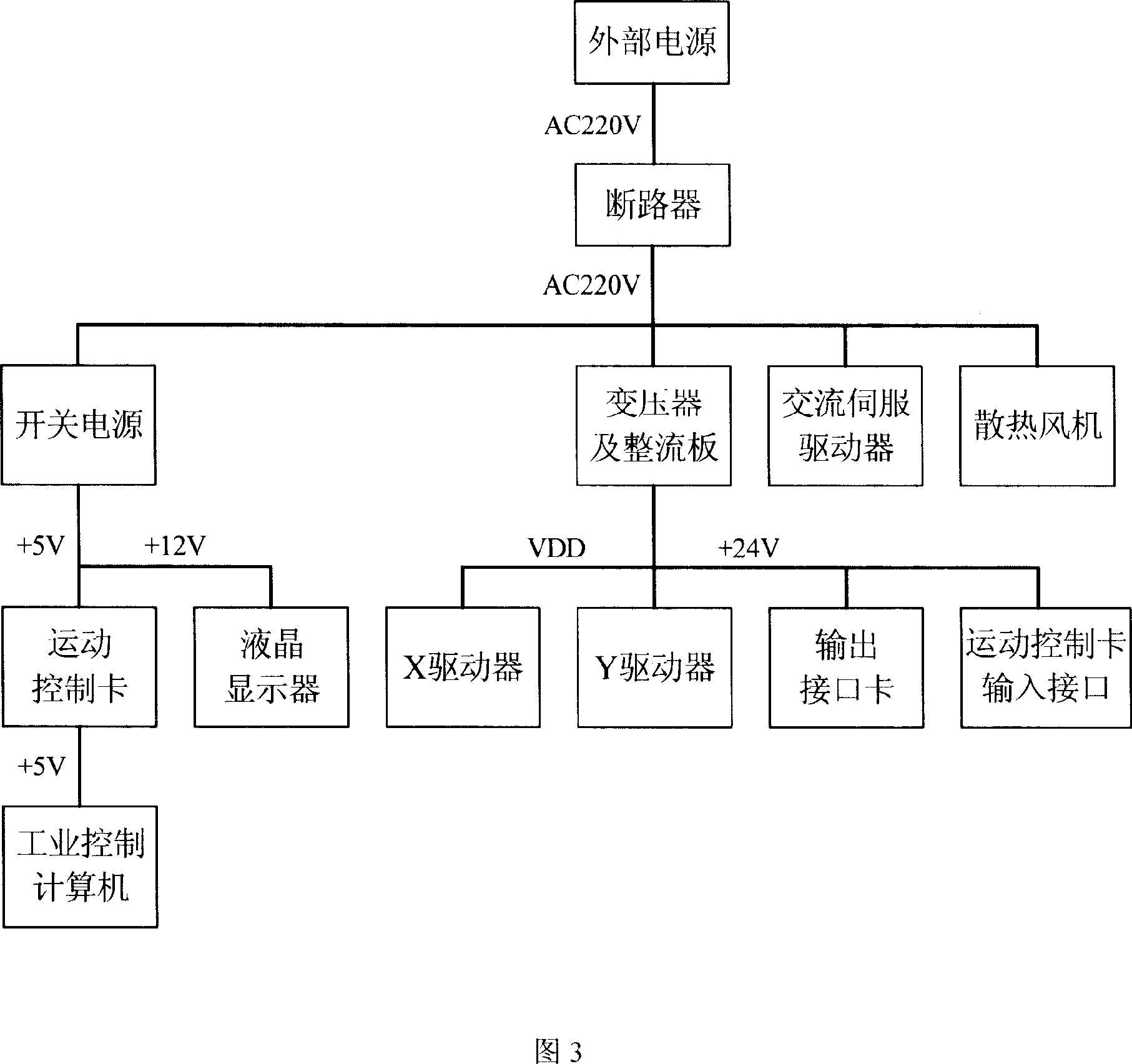

[0038] The industrial sewing machine computer control system of the present invention comprises a computer control unit, a servo drive unit, a man-machine interface unit and a system power supply unit. The computer control unit includes an industrial control computer (IPC) 1, a motion control card 2 and an output interface card 3; the servo drive unit includes a spindle driver 4 and a spindle motor 5, an X-axis driver 6 and an X-axis motor 7, a Y-axis driver 8 and a Y-axis driver Shaft motor 9, the main shaft motor adopts AC servo motor, and the X-axis and Y-axis motors adopt stepper motor or AC servo motor; the man-machine interface unit includes a color liquid crystal display 10 with touch screen function; the system power supply unit includes a switching power supply 11 and a transformer and rectifying plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com