Cloth feeding mechanism of sewing machine

A cloth feeding mechanism and sewing machine technology, applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine control devices, etc., can solve the problems of narrow application range, low cloth feeding efficiency, and inability to satisfy knitting and weaving at the same time, and reach the applicable scope Wide, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

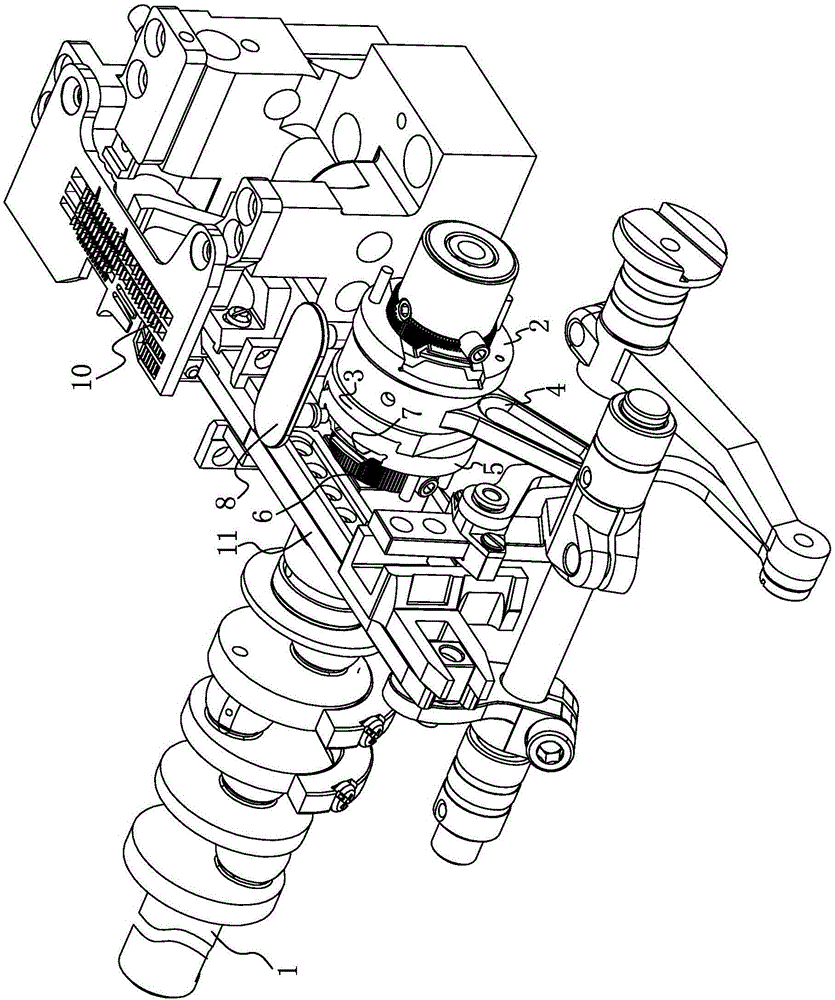

[0024] Such as figure 1 As shown, the sewing machine feed mechanism includes a main shaft 1 arranged in the sewing machine frame.

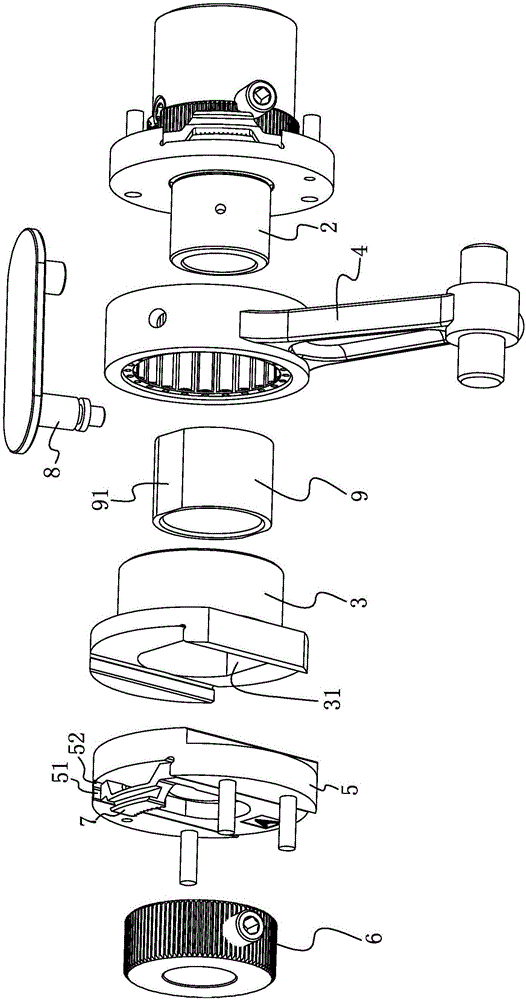

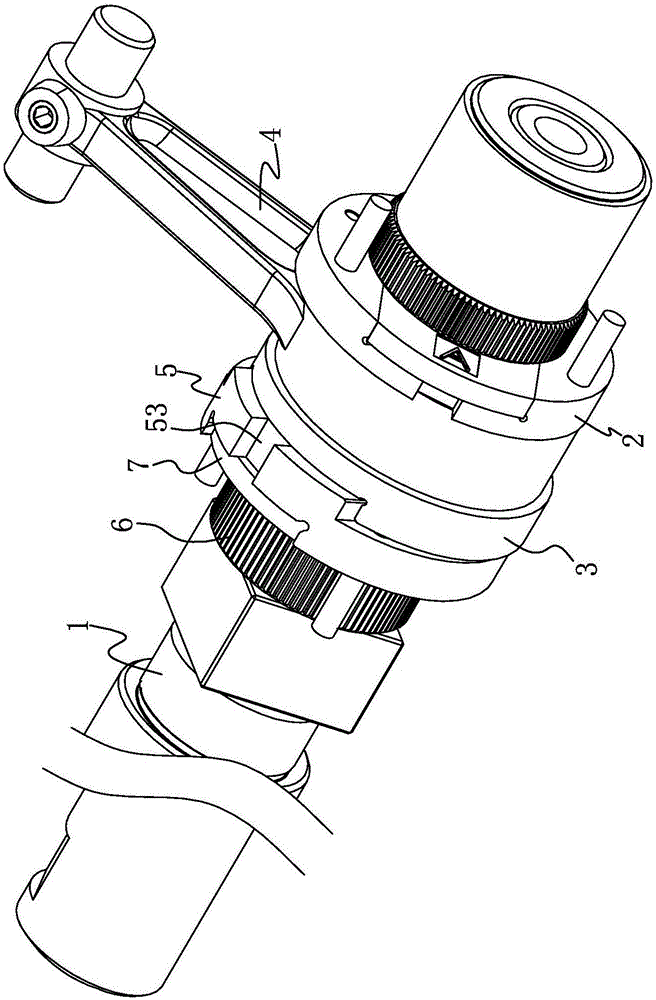

[0025] Such as figure 1 and figure 2 As shown, in this embodiment, a ratchet 6, a base 5, an eccentric wheel 3, a cloth feeding connecting rod 4, and a needle distance eccentric wheel 2 are sequentially set on the main shaft 1 from left to right, and the outside of the needle distance eccentric wheel 2 The cover is provided with a limit sleeve 9, and the limit sleeve 9 is located in the eccentric wheel one 3. Wherein, the ratchet 6, the base 5, the eccentric wheel 3, the needle distance eccentric wheel 2 and the limit sleeve 9 are all in the shape of a ring, and the end of the cloth feeding connecting rod 4 which is sleeved on the eccentric wheel 3 is also in the shape of a ring . One end of the eccentric wheel one 3 is slidably arranged on the base 5 along the radial direction of the main shaft.

[0026] Specifically, such as Figure 5 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com