Load bearing unit of carrying tool for babies

A technology for vehicles and infants, which is applied to children's carriages/baby carriages, children's carriages/cradle car accessories, motor vehicles, etc., and can solve problems such as time-consuming and troublesome, reduced riding comfort, and reduced seat strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structure of the carrying unit of the baby carrier is as follows:

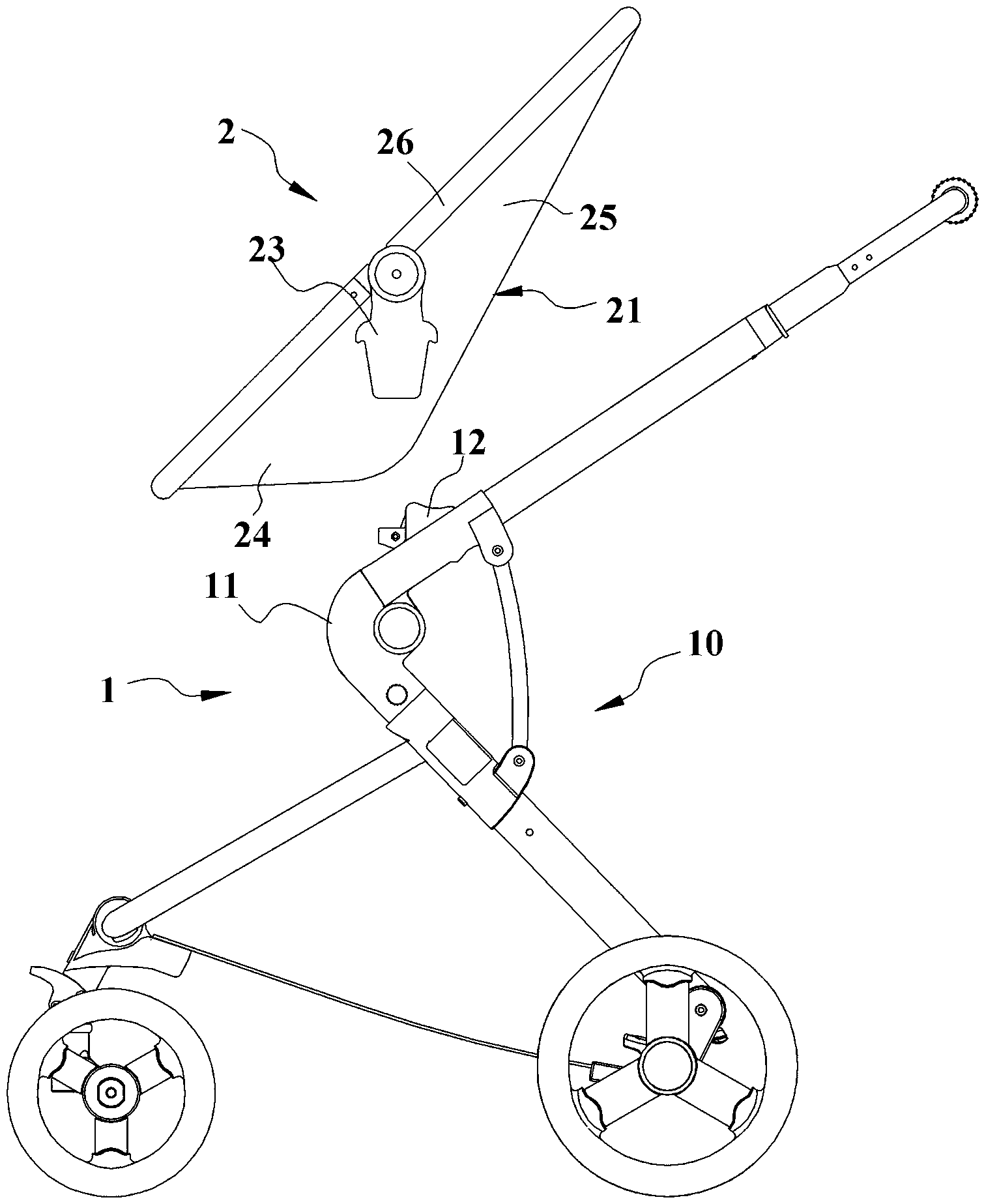

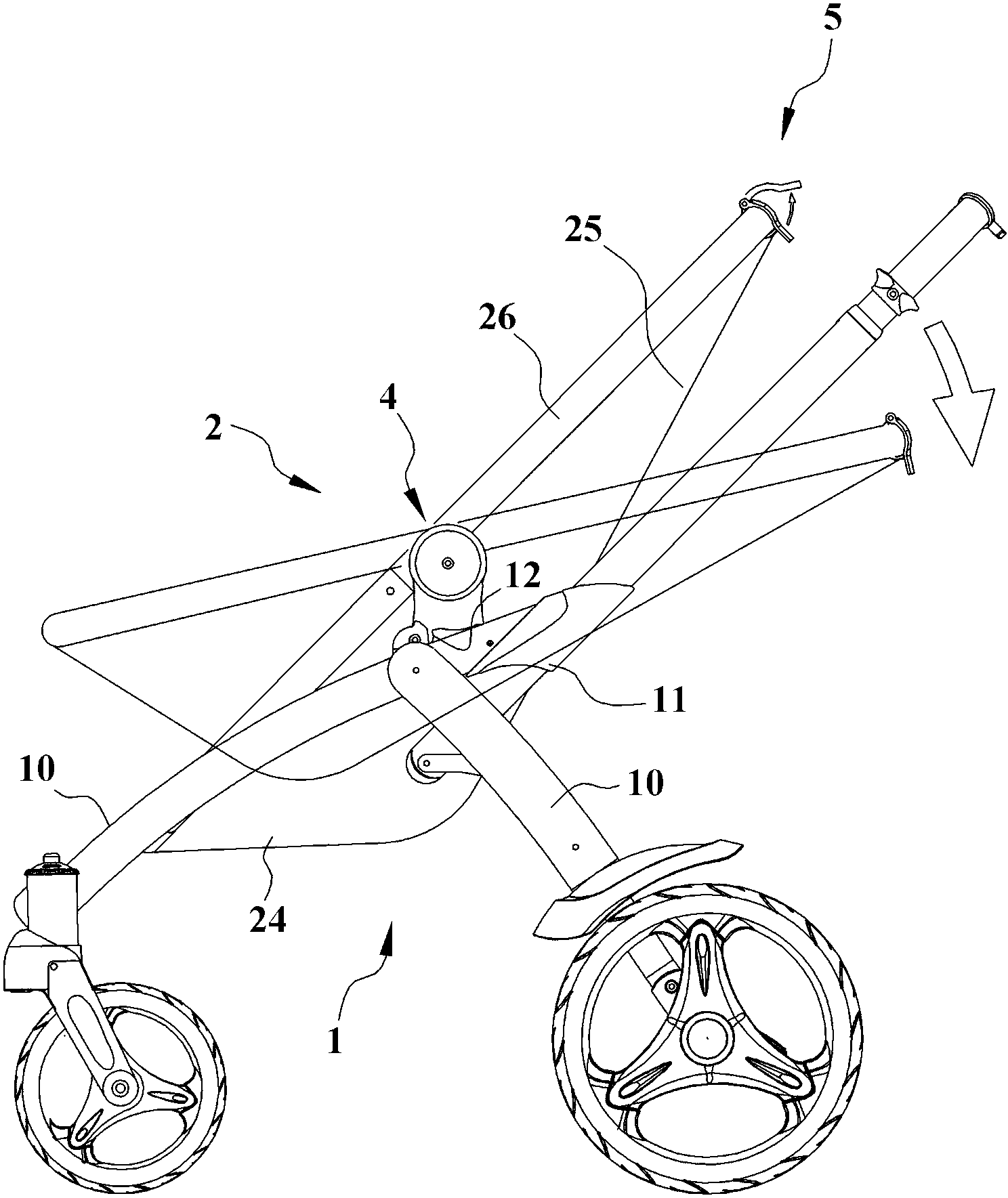

[0030] Such as figure 1 As shown, the baby carriage is composed of a plurality of branch pipes 10 and joint groups 11 pivotally connected to form a baby carriage skeleton 1, on which a socket 12 is provided for installing the carrying unit 2 of the present invention.

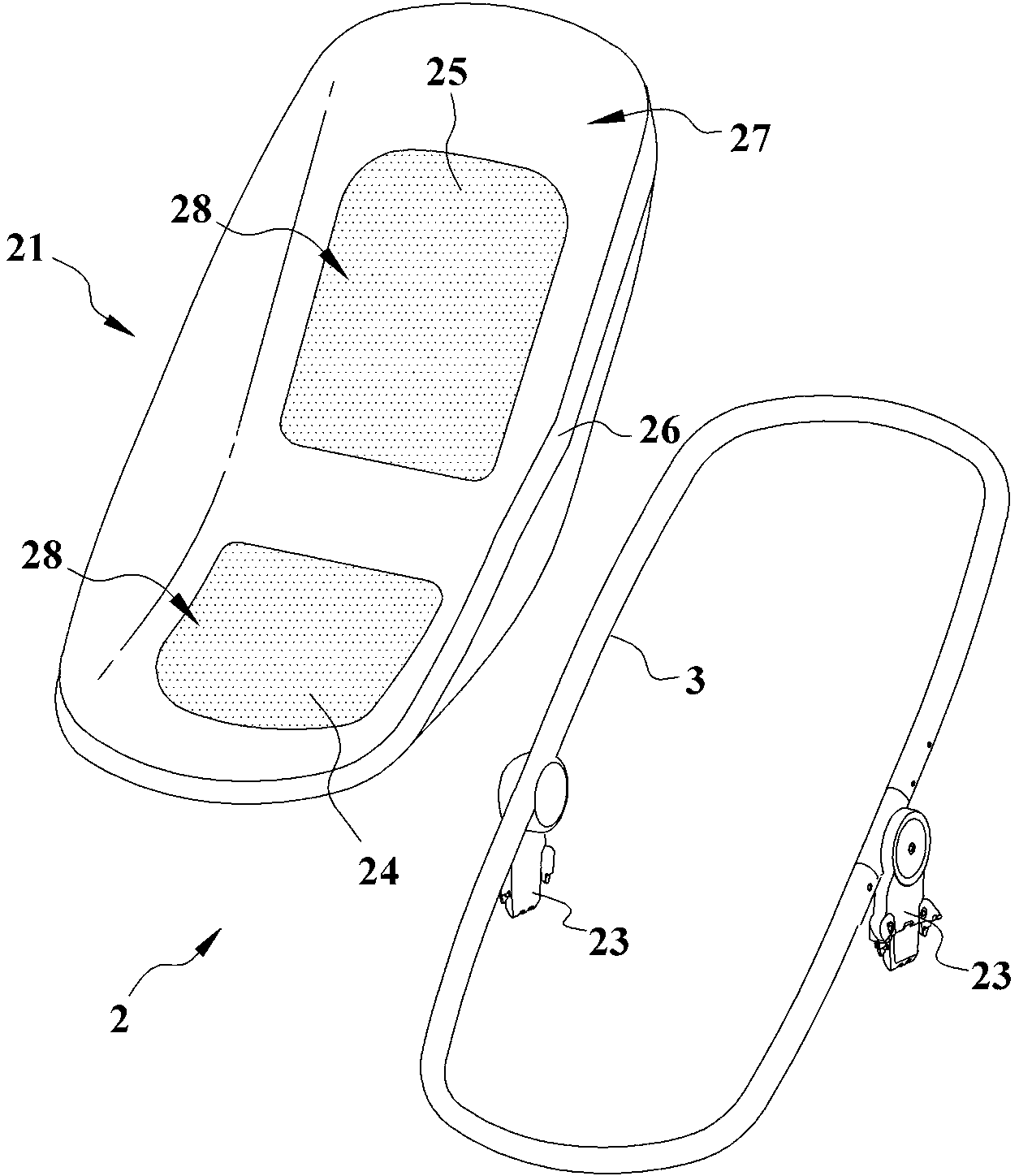

[0031] figure 2 The carrier unit 2 shown is composed of a body 21, a supporting frame 3 and a pair of inserts 23. The body 21 at least includes a seat portion 24, a back support portion 25 and a connecting portion 26. The connecting portion 26 is used for Connect the support frame 3; the body 21 can be made of a soft material, such as rubber, ethylene-vinyl acetate polymer in a mold integrally molded, or can be molded with two different physical properties, of which a softer material can be used to form the seat 24 And the back support part 25 to increase the comfort during riding, and the other parts are made of the second rigid material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com