Screw-drive adjusting type multi-angle cutting device for range hood processing

A cutting device and screw drive technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of consuming processing time, cumbersome operation steps, and reducing production efficiency, so as to increase the contact surface and contact time, Ease of use and improved photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

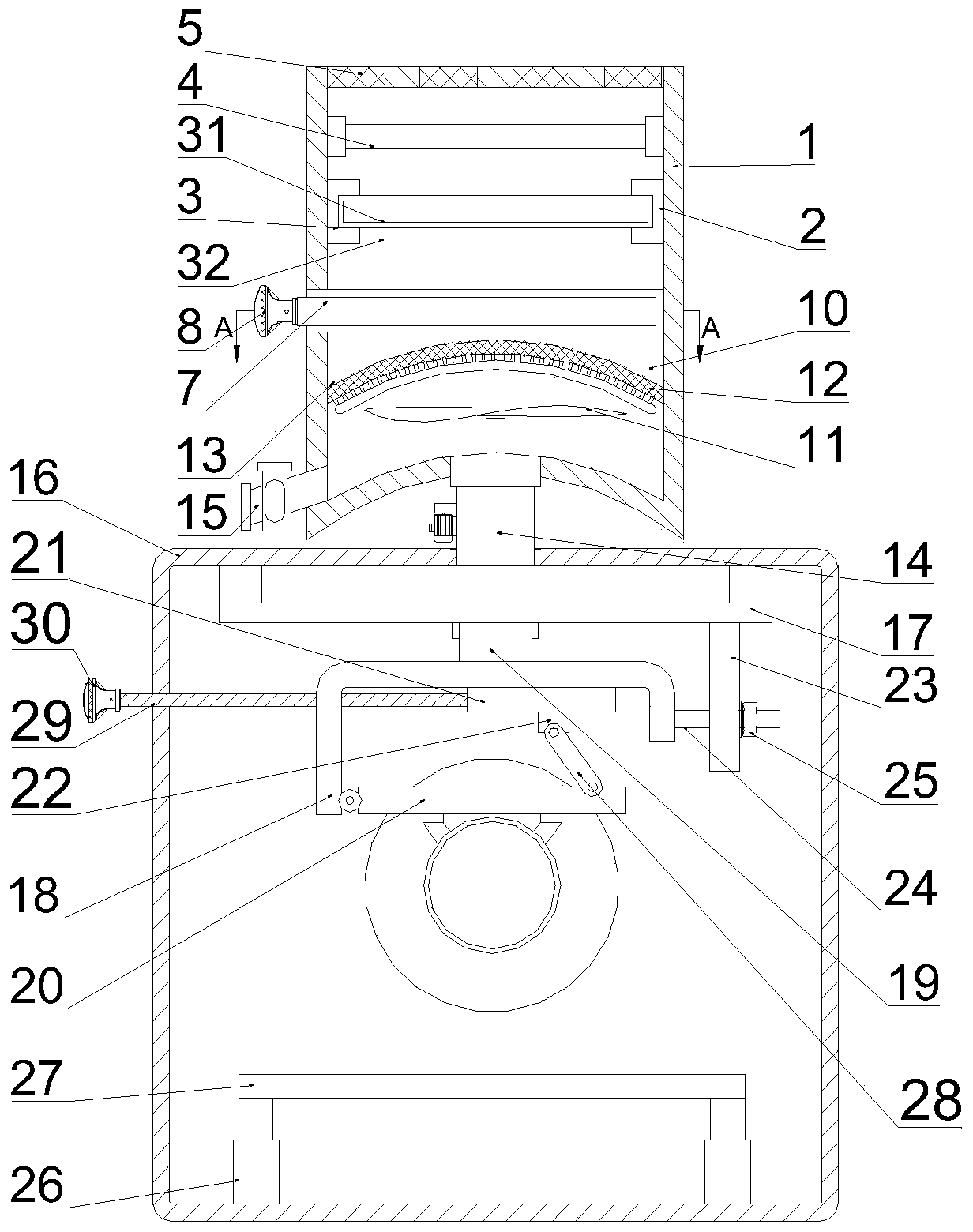

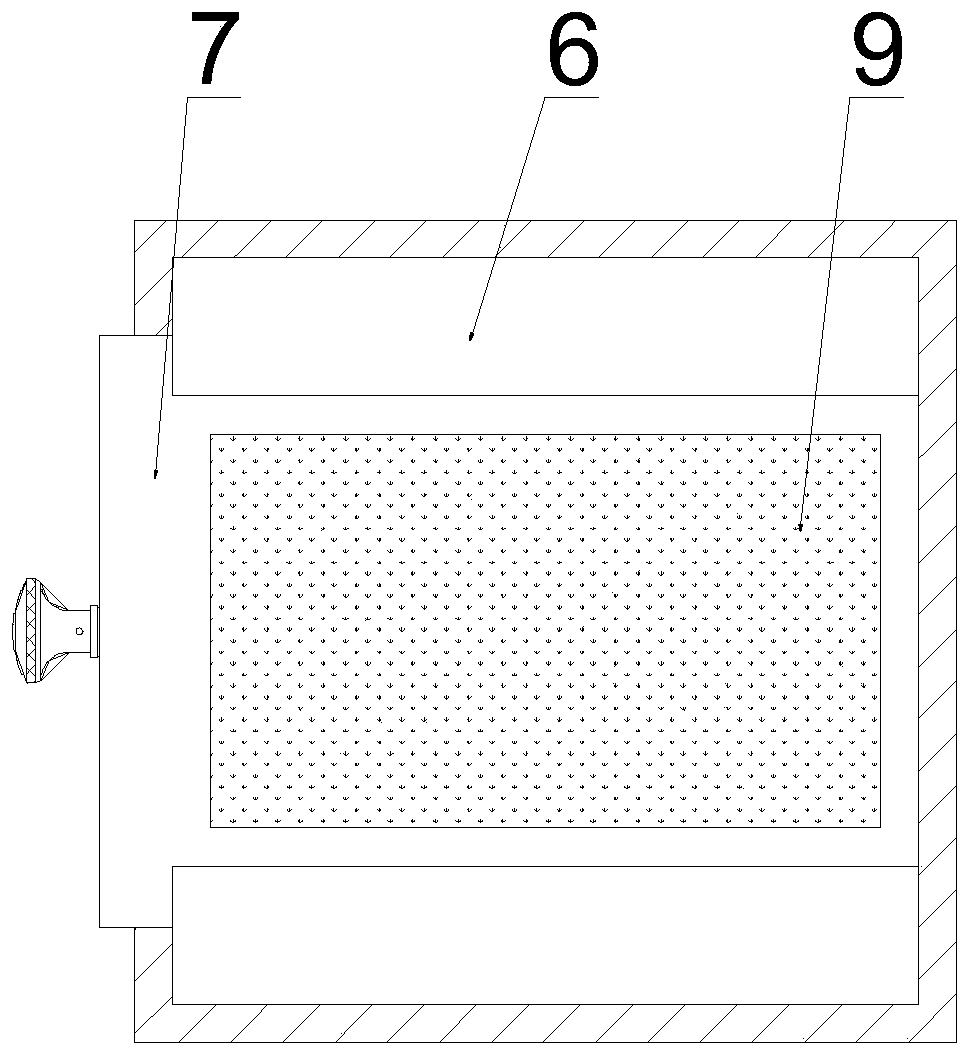

[0025] see Figure 1-2 , a screw-driven adjustable multi-angle cutting device for processing fume machines, comprising a cutting box 16, a multi-angle cutting device installed on the upper side of the cutting box 16, an elevating processing table device installed on the lower side of the cutting box 16, and settings In the cleaning box 1 on the top of the cutting box 16, the multi-angle cutting device includes a mounting frame 17 fixedly connected to the upper inner wall of the cutting box 16, and the bottom of the mounting frame 17 is provided with a U-shaped frame 18 that is arranged in an inverted U-shape The top of the U-shaped frame 18 is fixedly connected to the connecting plate 19 arranged horizontally, the other end of the connecting plate 19 is hinged with the U-shaped frame 18, the bottom of the U-shaped frame 18 is provided with a motor,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com