Air purification device for chemical gas production

An air purification device and gas production technology, applied in gas treatment, transportation and packaging, climate change adaptation, etc., can solve the problems of enterprise cost burden, high manufacturing cost, inconvenient cleaning and cleaning of filter devices, etc. The effect of increased contact time and enhanced photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

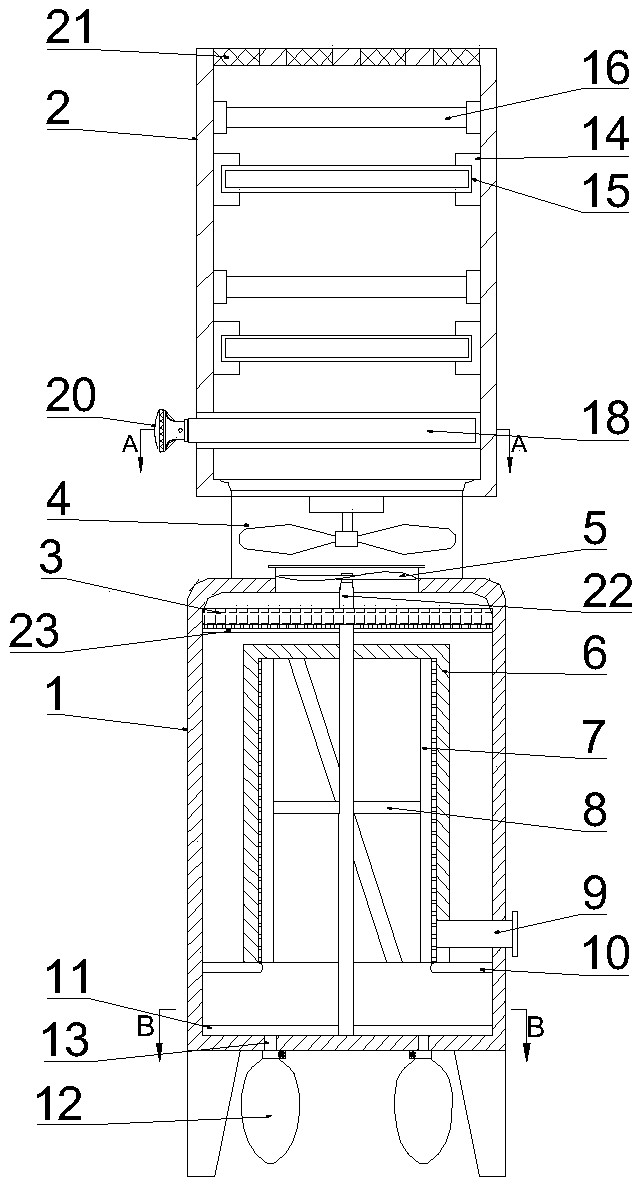

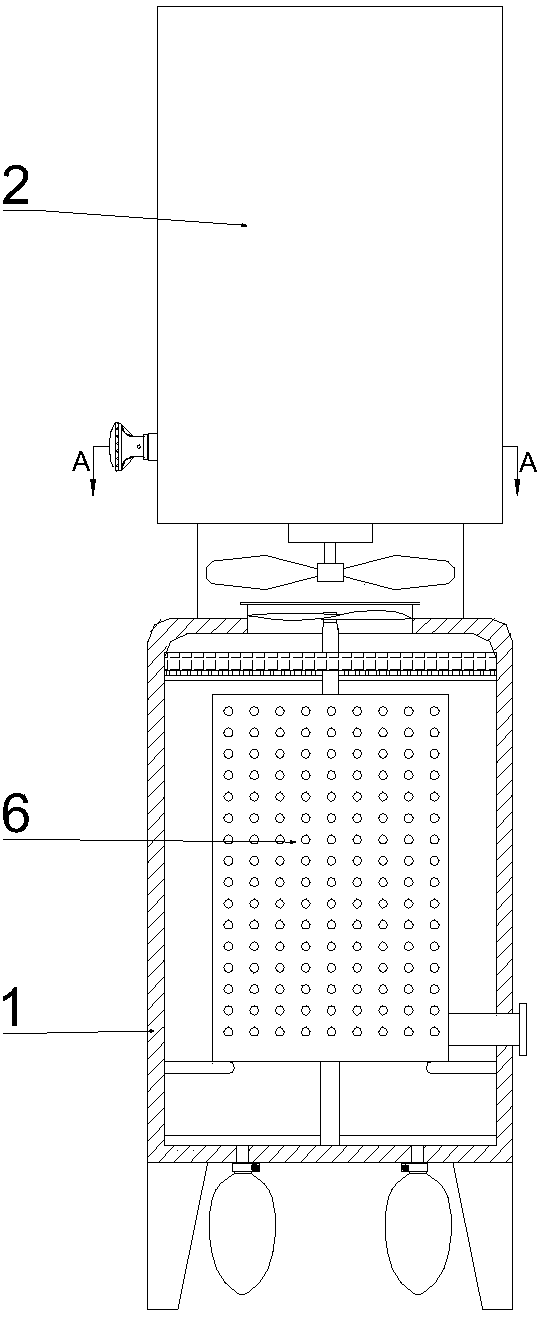

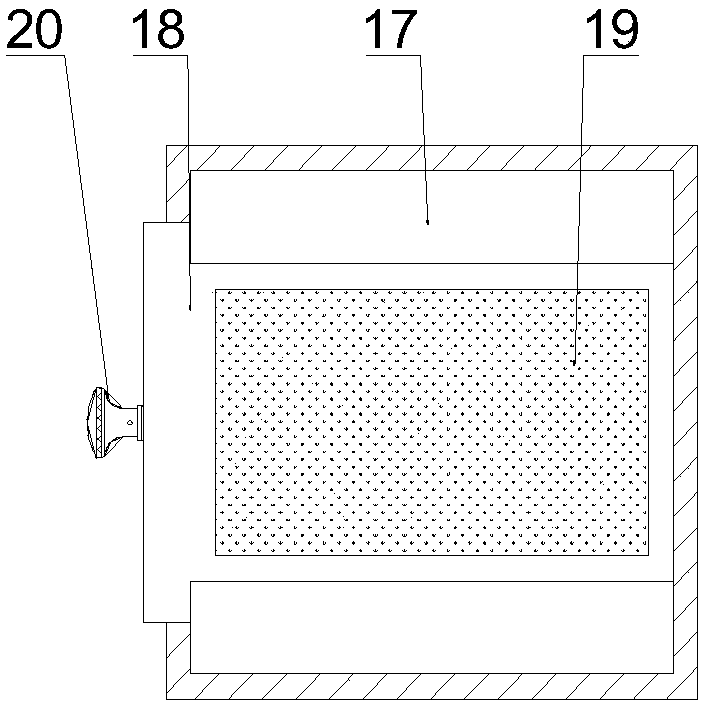

[0019] see Figure 1-4 , an air purification device for chemical gas production, comprising an upper cylinder 2 and a lower cylinder 1, the lower side of the inner wall of the lower cylinder 1 is fixedly connected with a plurality of support rods 10 along the circumferential direction, and the upper part of the support rod 10 The inner cylinder 6 with the lower end opening is fixedly connected, and the circumferential surface of the inner cylinder 6 is evenly provided with a number of sieve holes. 1 is fixedly installed with an axial flow fan 4, and the lower part of the axial flow fan 4 is provided with a propeller 5, and the upper side of the inner wall of the lower cylinder 1 is fixedly connected with a first filter screen 3, and the lower part of the axial flow fan 4 is fixedly connected with a The rotating column 22 that moves through the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com