Method for automatically tracking unilateral sewing laser visual sense paths of composite material three-dimensional structural member

A composite material and three-dimensional structure technology, applied in sewing equipment, sewing machine components, program-controlled sewing machines, etc., to achieve the effects of single-sided sewing path tracking, rapid positioning, and improved calibration efficiency and calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

[0044] Such as Figure 1 to Figure 7 as shown,

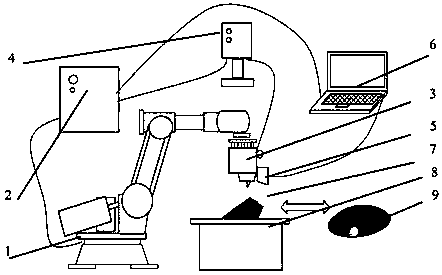

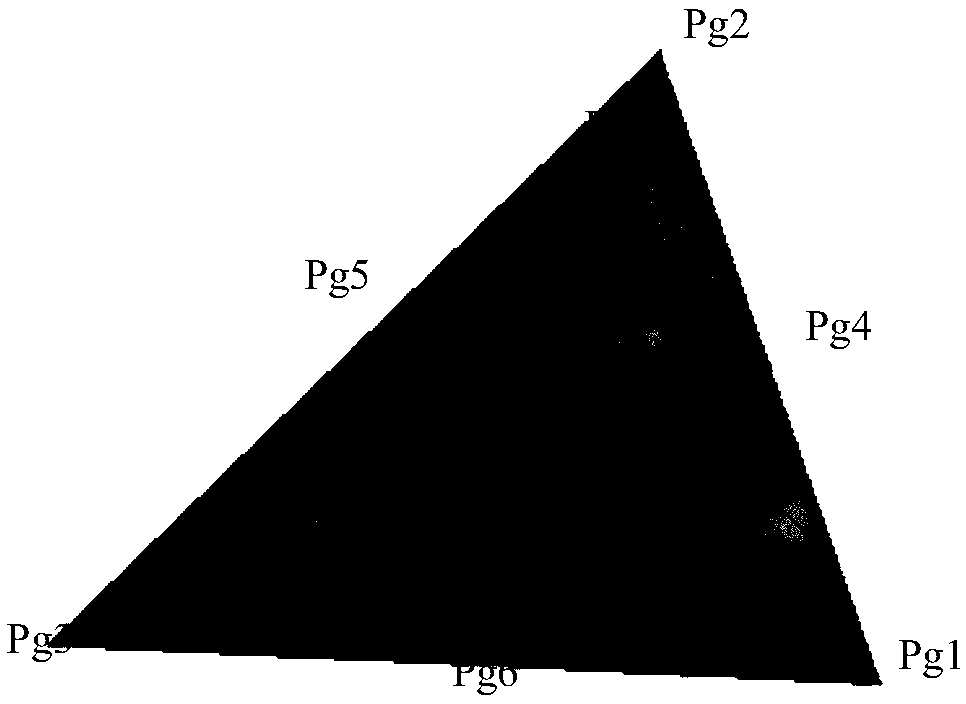

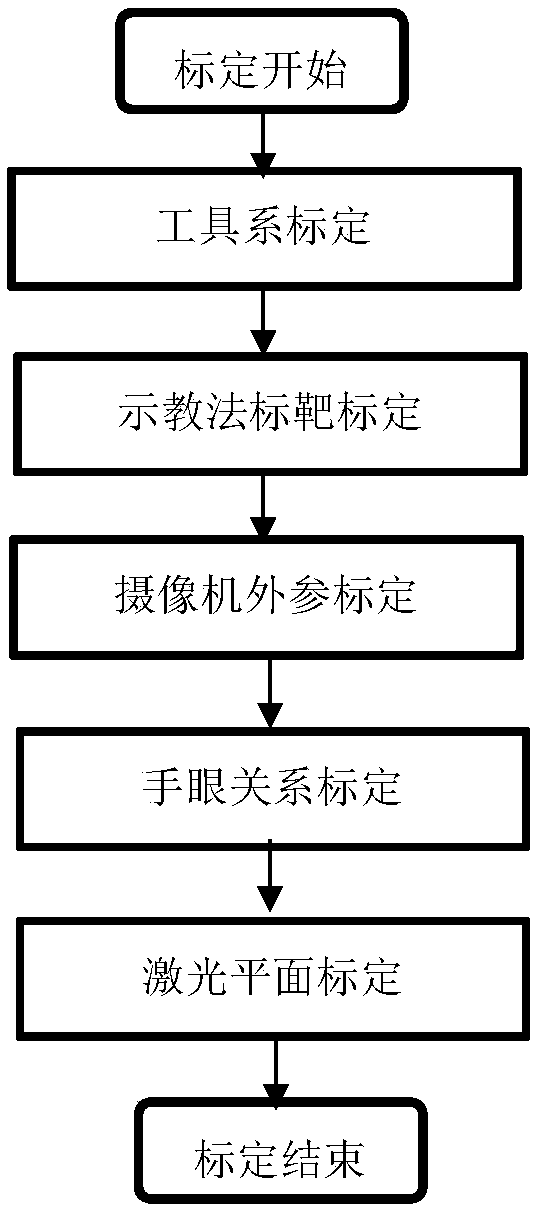

[0045] figure 1 The unilateral sewing robot and the three-stripe laser vision tracking system include an industrial robot 1 and its matching control cabinet 2, a composite material unilateral sewing head 3 is installed at the end of the mechanical arm, and its dedicated control system 4 is controlled by the robot through the Profibus bus technology Coordinated communication of the system; the three-stripe laser vision sensor 5 is installed at the front end of the composite material single-side sewing head 3 for image acquisition during the composite material sewing process, and the computer 6 performs the extraction of the spatial position of the sewing curve and the calculation of the sewing posture, And communicate with the robot electric control cabinet through industrial Ethernet; during calibration, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com