Numerically controlled single-needle quilter

A quilting machine, single-needle technology, applied in sewing machine components, sewing machines for sewing quilts, cloth feeding mechanisms, etc., can solve the problems of inability to achieve thick fabrics, complex and unreasonable structure, slow quilting speed, etc., and achieve a simple structure. , The effect of good quilting stability and fast quilting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

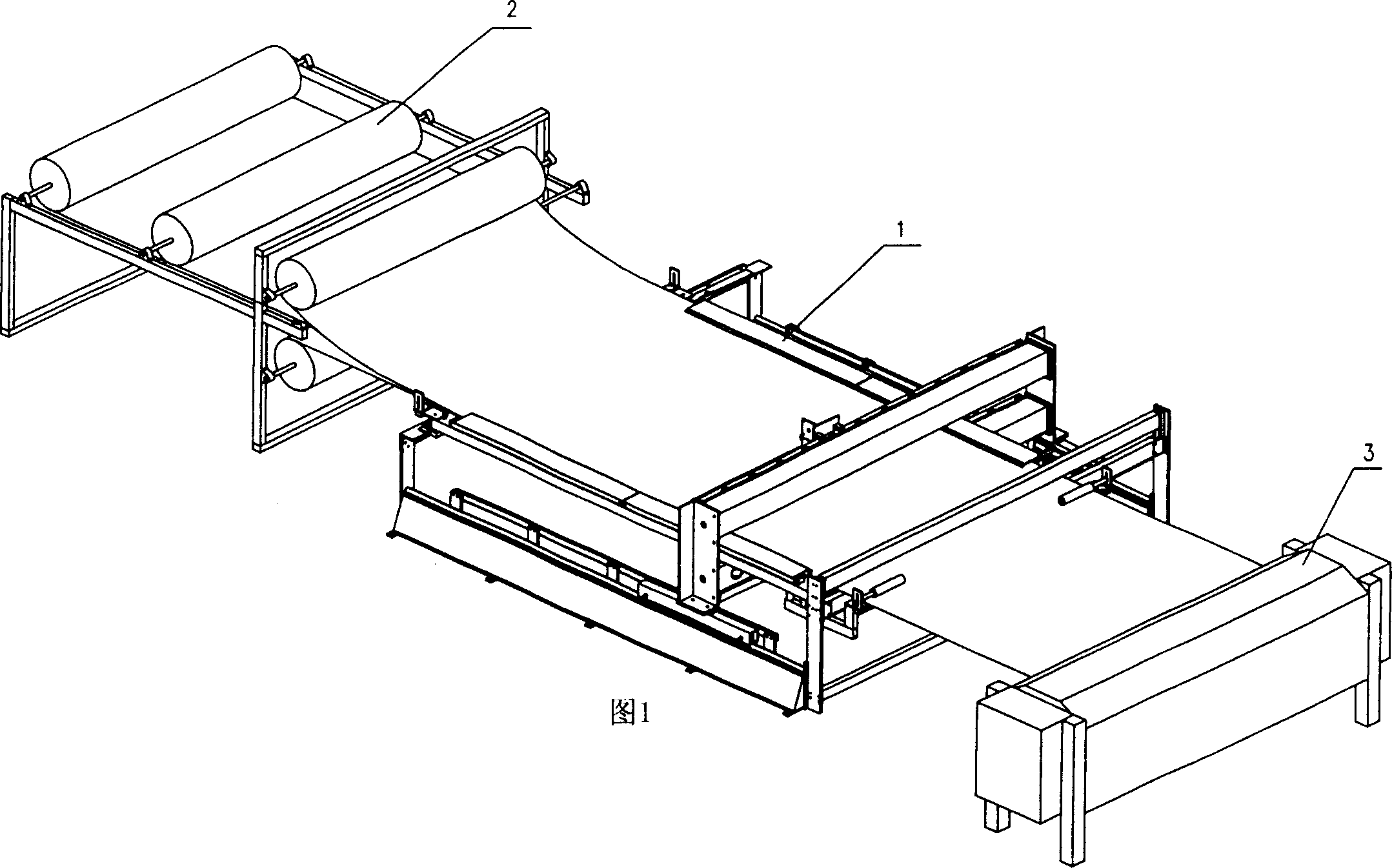

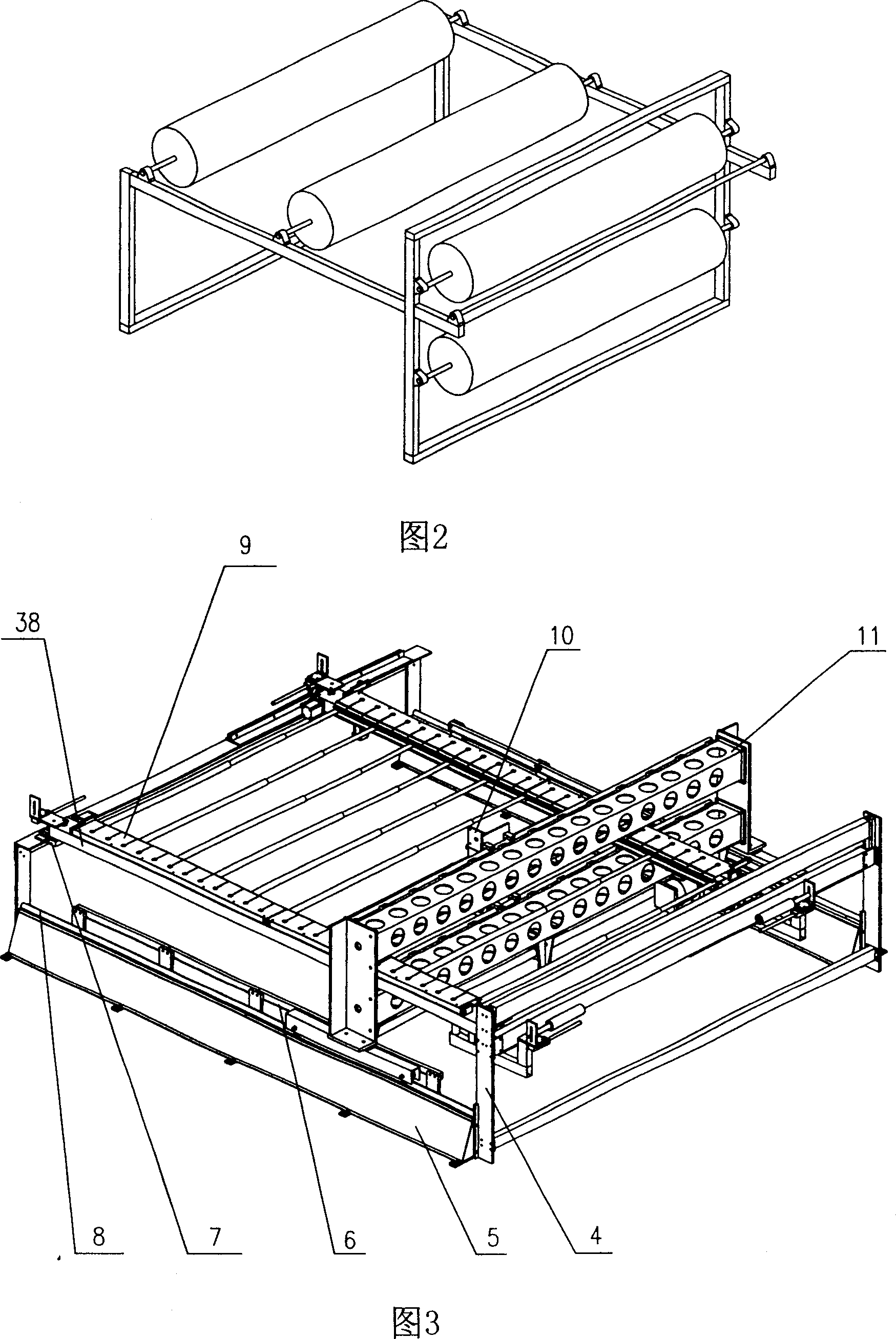

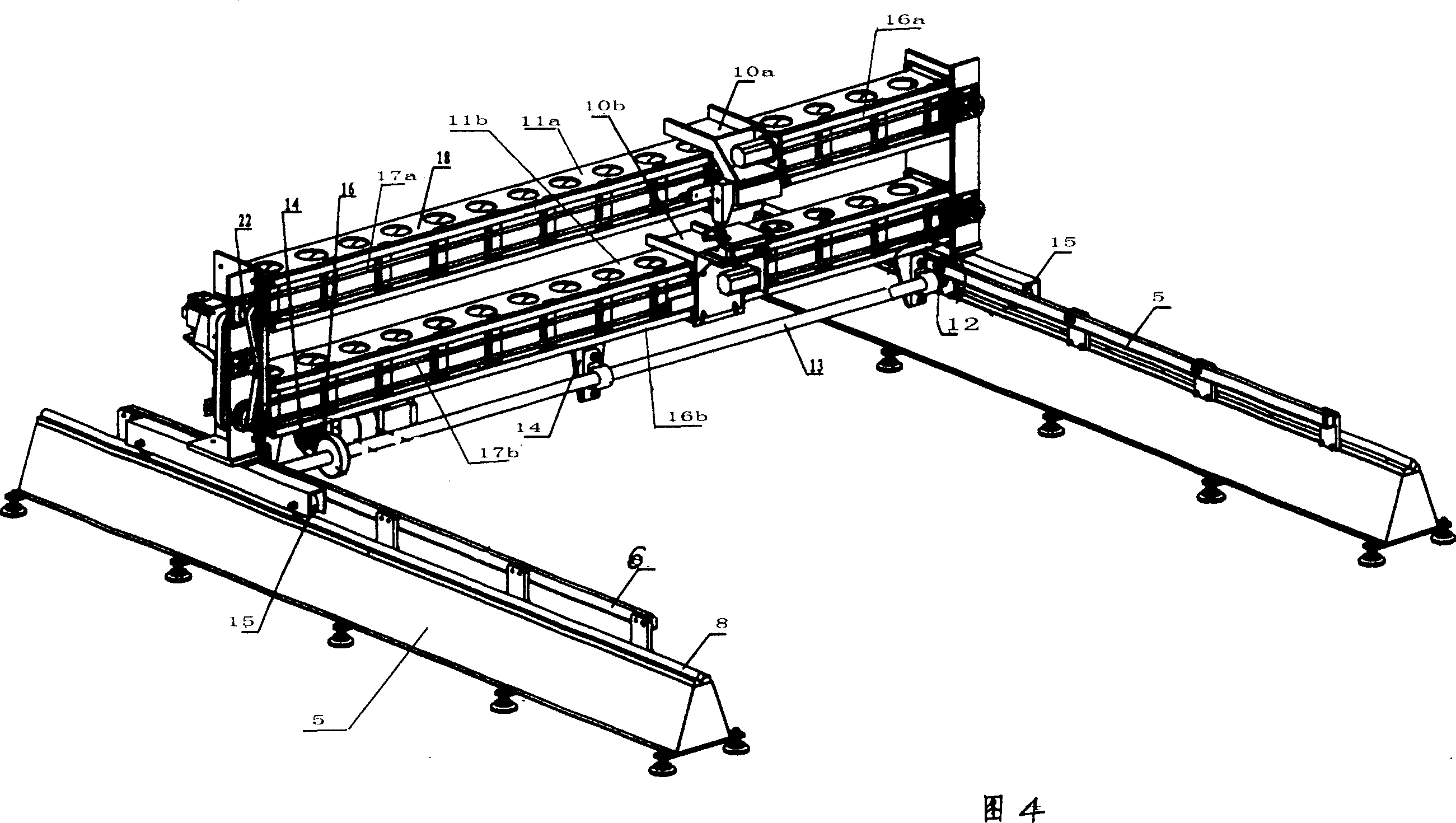

[0020]As shown in Figure 1, the CNC single-needle quilting machine is composed of four independent parts: the cloth feeding support frame 2, the main body of the quilting machine 1, the tensioning device 3 with a cross cutter and the electric control cabinet. As shown in Figure 2, the cloth feeding support frame is composed of a support frame and several cloth rolls mounted on the support frame, and is used to transmit the cloth to the main body of the quilting machine. As shown in Figure 3, the main body of the quilting machine is composed of a frame 4, a machine head 10, a gantry moving device, a machine head moving timing belt device, and a fabric adjusting and clamping mechanism. The cores 10 are an upper core 10a and a lower core 10b. As shown in Figure 3 and Figure 4, the gantry moving device is provided with two parallel gantry bases 5 and gantry 11 symmetrically arranged, and the upper and lower frame bodies 11a and 11b of the gantry 11 are respectively parallel to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com