Movable type double rotary shuttle stent mechanism

A support mechanism and a double-rotating hook technology, which are applied to sewing machine ring mechanisms, sewing machine components, textiles and papermaking, etc., can solve the problems of thin quilting fabrics, slow quilting speed, and inability to quilting patterns of different sizes Requirements and other issues, to achieve the effect of thick quilted fabric and fast quilting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

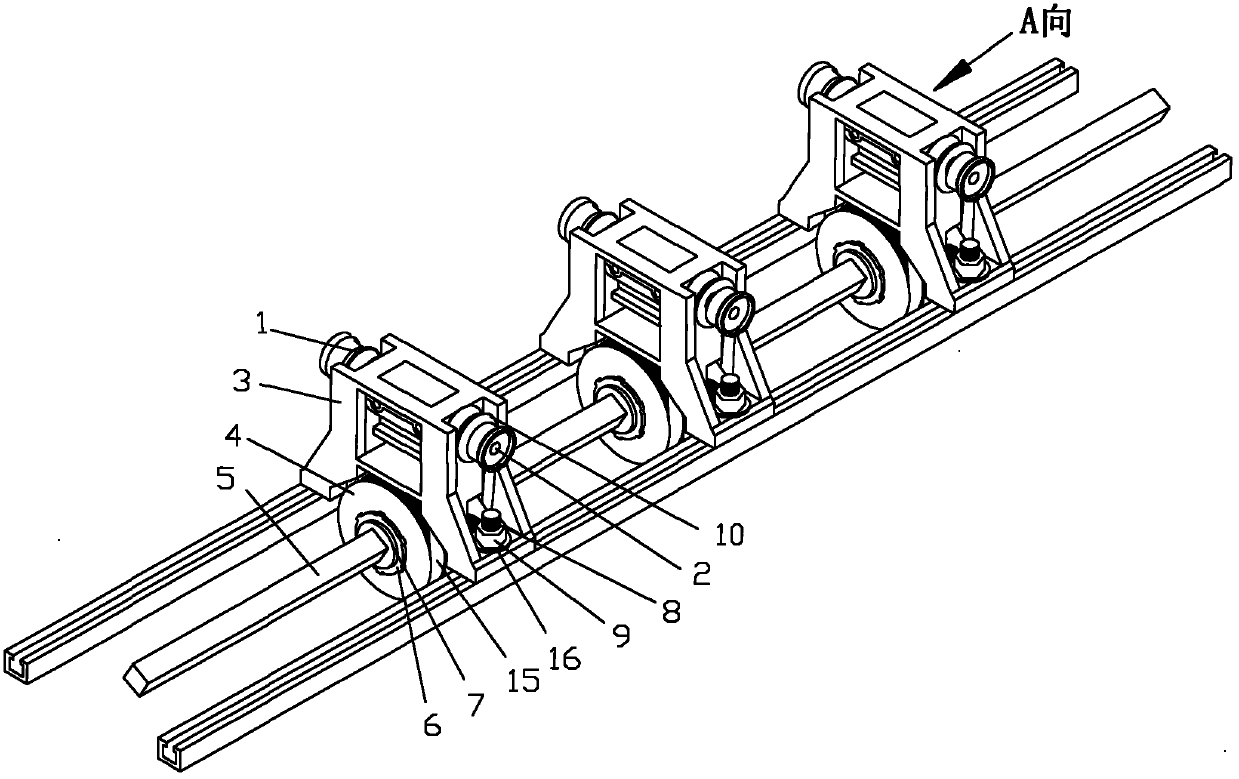

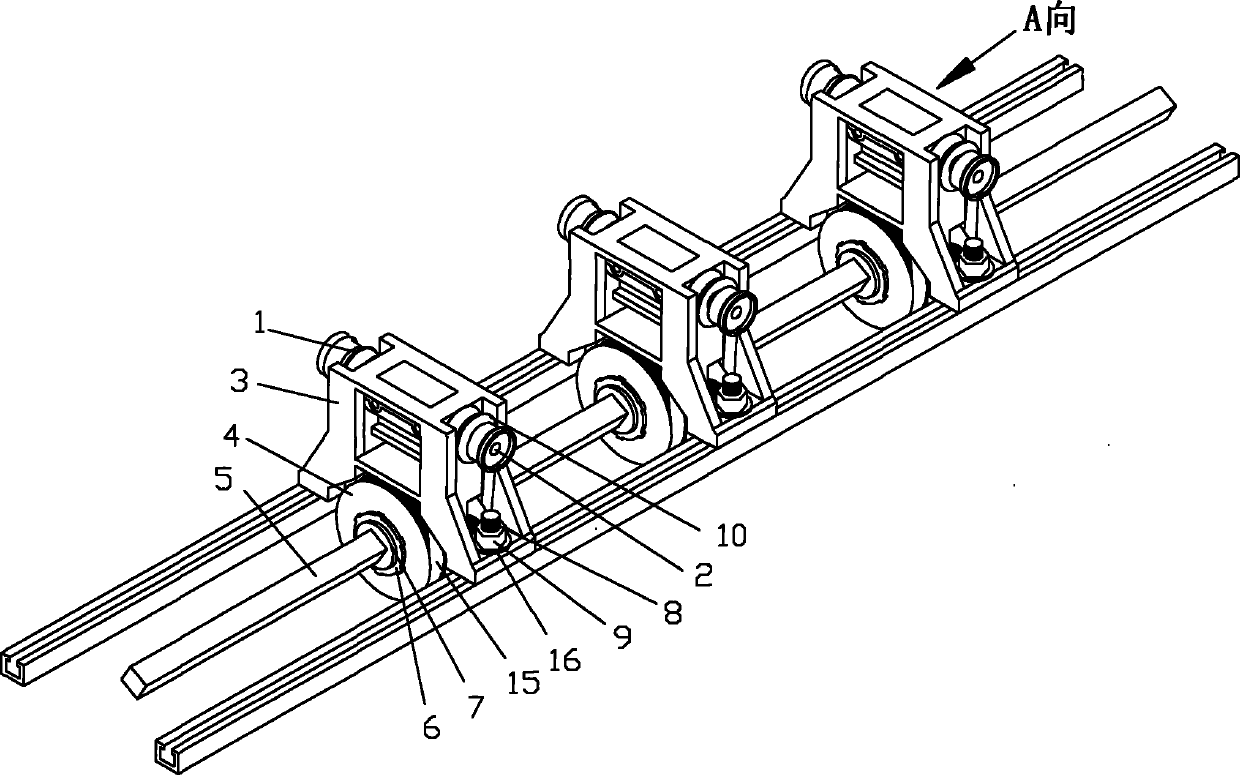

[0012] Such as figure 1 As shown, the present invention is provided with the rotary hook support 3, and the large bearing is externally fixed in the rotary hook support, the shaft 7 passes through the inner hole of the large bearing, the first synchronous wheel 4 is also sleeved on the shaft 7, and then the retaining ring 6 Clamped in the groove at the shaft 7 to fix the outer end of the synchronous wheel 4, the main shaft 5 passes through the inside of the shaft 7, so that the stepper motor drives the main shaft to rotate, and it can be brought to the synchronous wheel 4 to rotate accordingly.

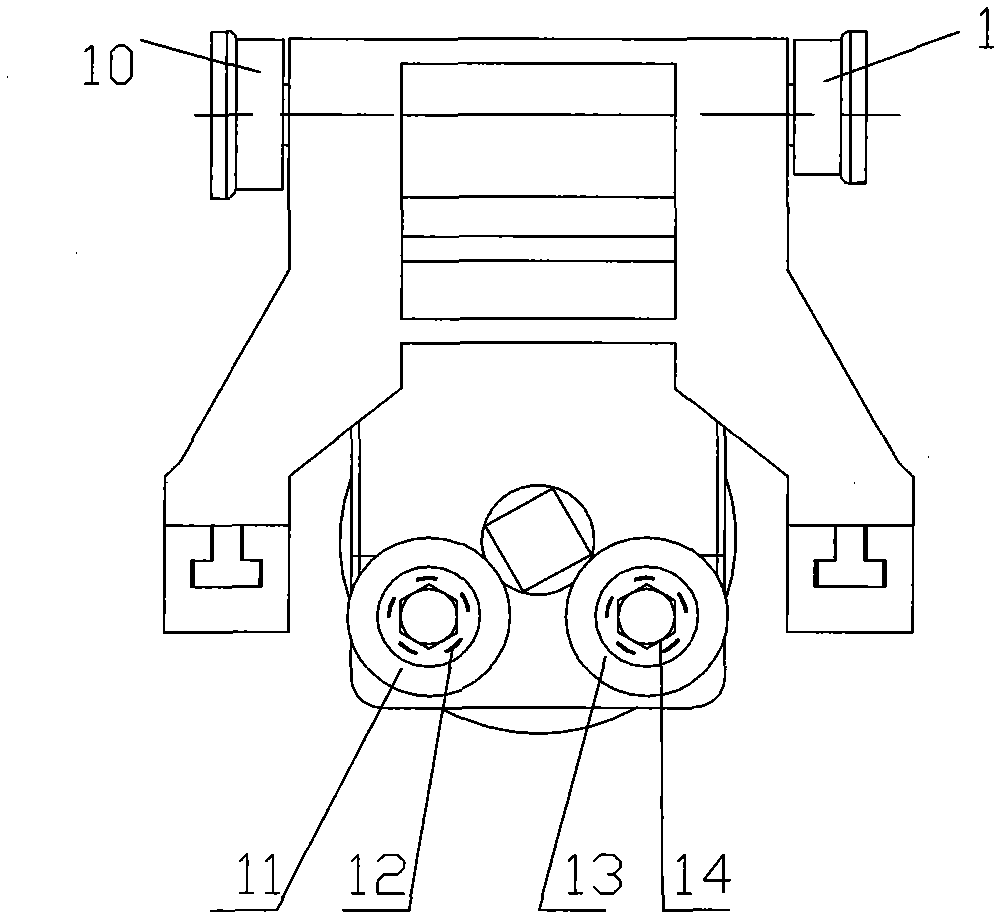

[0013] Such as figure 2 As shown, two shafts 12 are fixed in the holes of the rotary hook bracket 3, and the outer circles of the two shafts 12 are respectively sleeved in two bearing holes, and the outer circles of the two bearings are respectively sleeved on two tensioning wheels (11, 13) in the hole, fix the outer end of tensioning wheel (11,13) respectively with two washers, loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com