Steel reinforced concrete beam pouring and tamping support-free suspension molding plate structure and method

A concrete beam, unsupported technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connection, building structure, etc., can solve the problem of not being able to take advantage of the bearing capacity of section steel beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

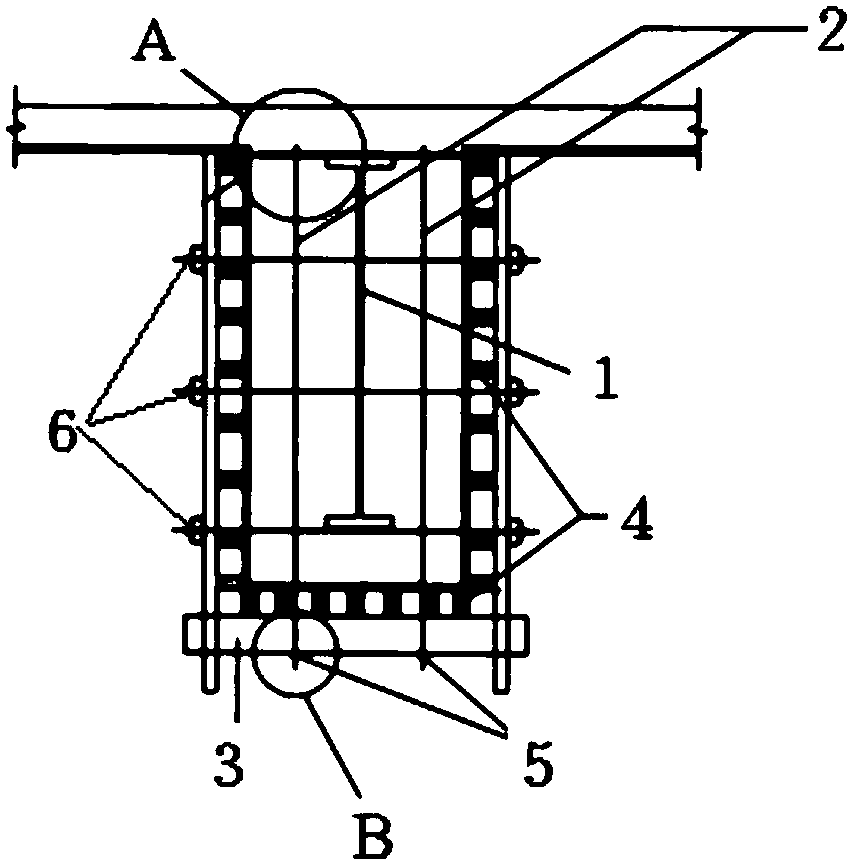

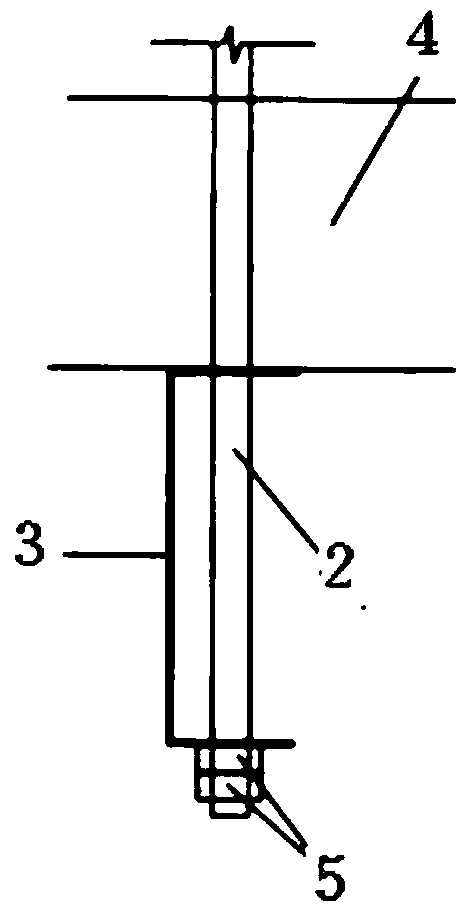

[0035] Such as Figure 1 to Figure 3 As shown, a beam formwork suspension structure poured and rammed for unsupported steel concrete structure beams includes suspenders 2, steel bars 7, steel plates 8, 14# channel steel 3, wood squares 4, tension bolts 6, and nuts 5. There is a suspender 2 on both sides of the steel beam 1, the upper part of the suspender 2 is fixed on the upper wing of the steel beam 1, the lower part of the suspender 2 passes through the wooden square 4 at the bottom of the steel beam 1, and an additional 14# channel steel 3 with a distance of 1000mm, the bottom of the 14# channel steel 3 is fixedly connected to the suspender 2 with two nuts 5; fixed.

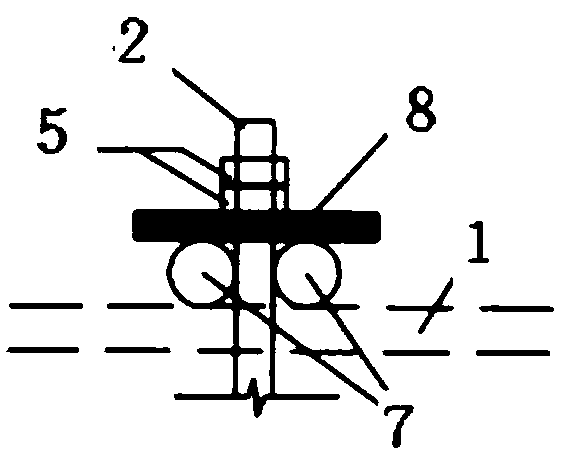

[0036] Such as figure 2 As shown, the upper part of the suspender 2 and the upper wing of the steel beam 1 are fixedly connected by two 25mm steel bars 7, a 10mm thick 100mm*100mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com