Beam plate post-cast strip template support system and construction method thereof

A formwork support and post-casting belt technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problem of difficult removal of loose concrete on both sides of the post-casting belt, and the safety and quality of the main structure cracking , Concrete pouring and tamping at the post-pouring belt is not compact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

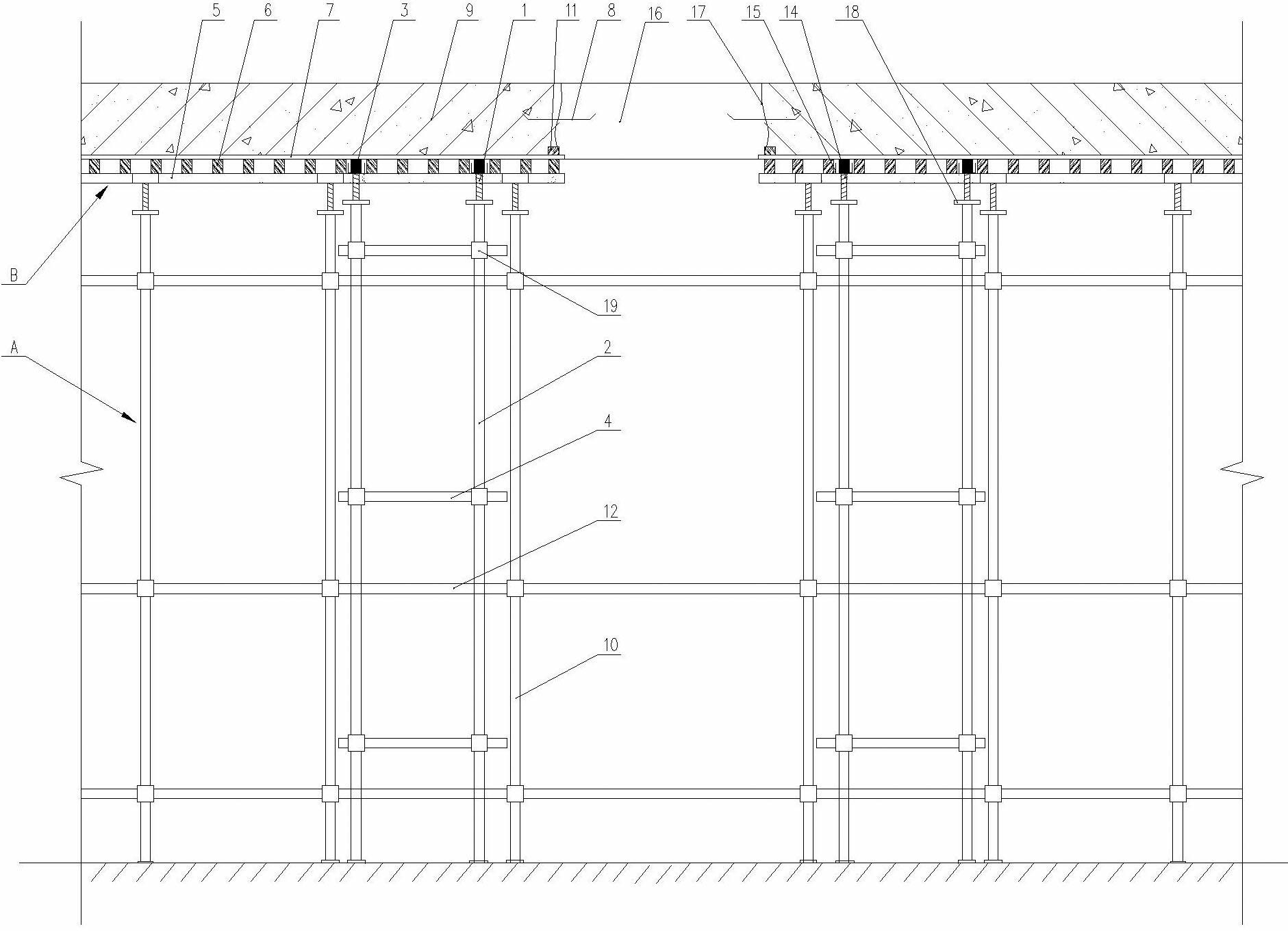

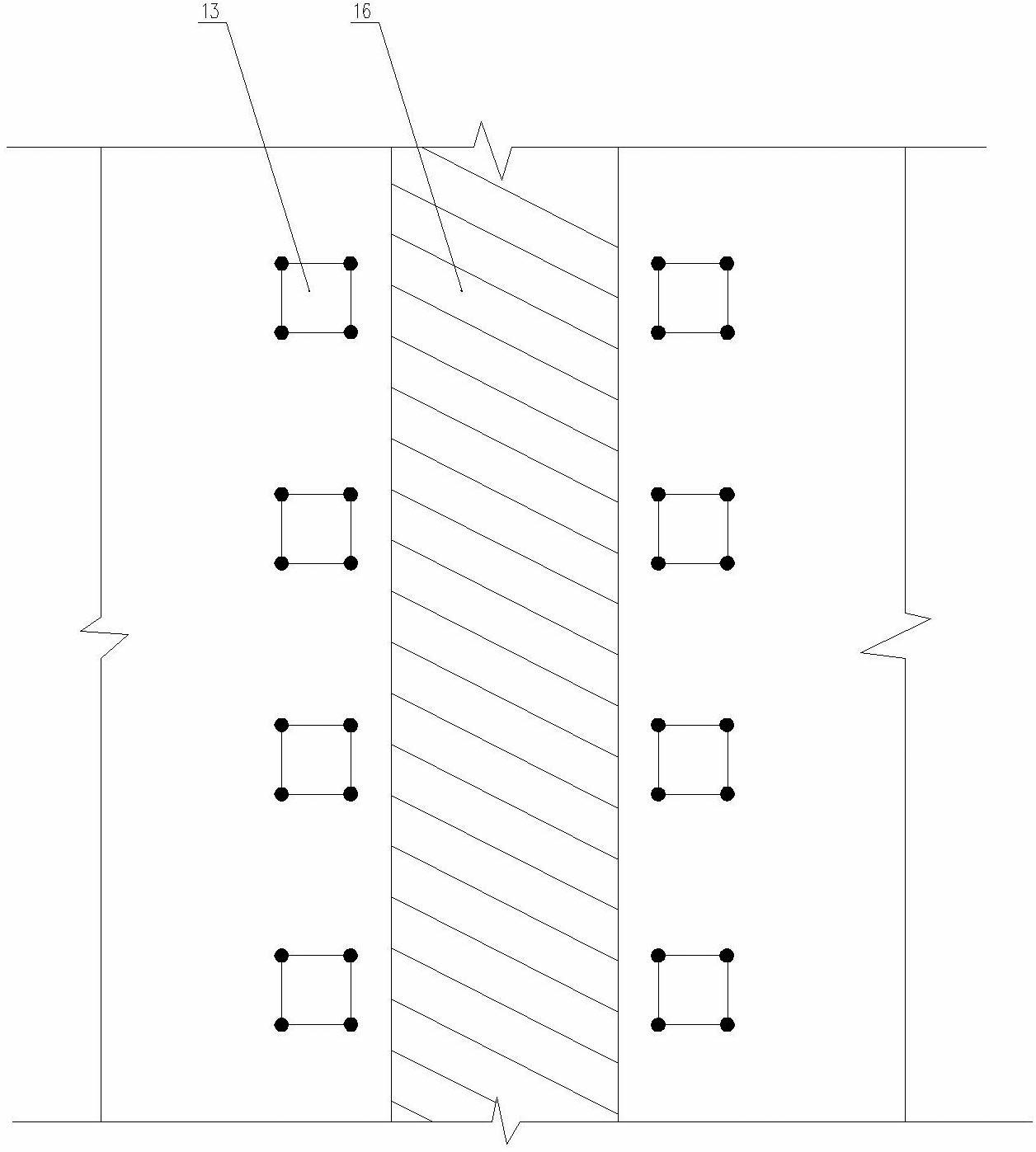

[0023] Preferred embodiment one, such as figure 1 , figure 2 As shown, the present invention is used for the construction of a reinforced concrete slab support system without beams and with post-cast belts. Its construction steps are as follows:

[0024] First set up the main formwork support system: it includes the support frame body A standing on the ground or the floor and the support corrugated system B arranged horizontally on the support frame body A. The support frame body A is a support pole 10 and a horizontal connecting rod 12 through steel A support formwork frame system formed by a connection method of fastener type, disc buckle type or bowl buckle type. The top of the support pole 10 has an adjustable jacking 1, and the support flute system B includes the main flute 5 and the secondary flute 6. The secondary flute 6 is evenly arranged on it perpendicular to the main flute 5. Both the main flute 5 and the secondary flute can be made of wooden squares, square ste...

Embodiment 2

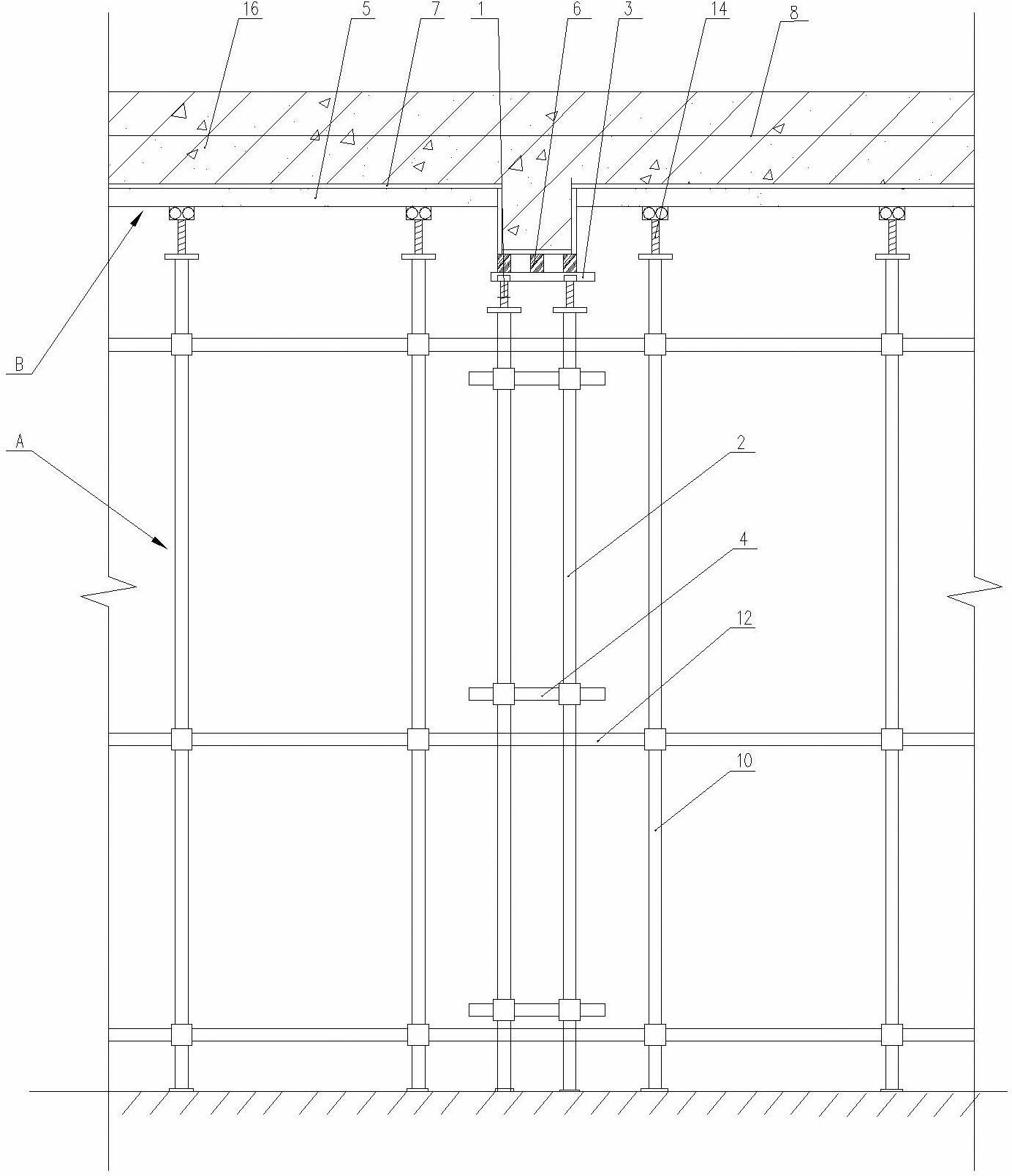

[0032] Preferred embodiment two, such as image 3 , Figure 4 As shown, the present invention is used for the beam-slab support system construction of the post-cast belt with beams passing through. The basic construction steps are the same as the previous embodiment, except that the supporting position of the supporting lattice column is at the end of each beam near the rear pouring belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com