Supporting system of pre-stressed concrete laminated slab of shear wall structure

A technology of support system and shear wall, which is applied in on-site preparation of building components, building structure, formwork/formwork/work frame, etc., can solve the problems of unguaranteed strength, poor concrete appearance and low safety factor, etc. To achieve the effect of simple and convenient construction operation, reduce pollution and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

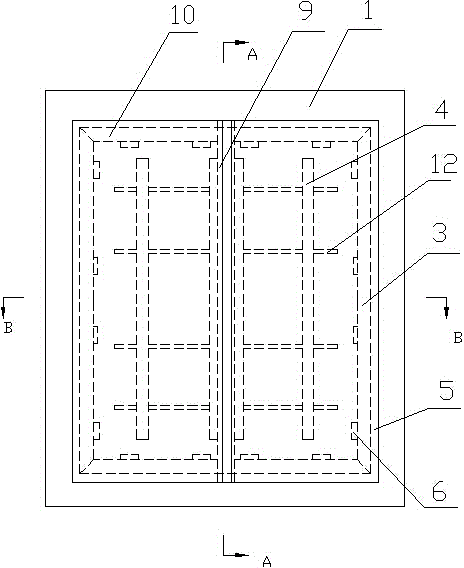

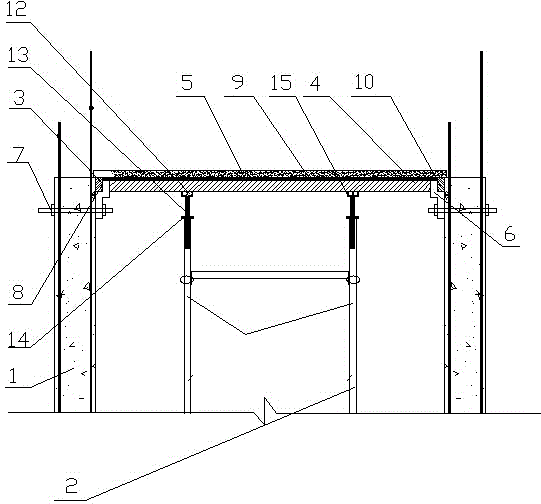

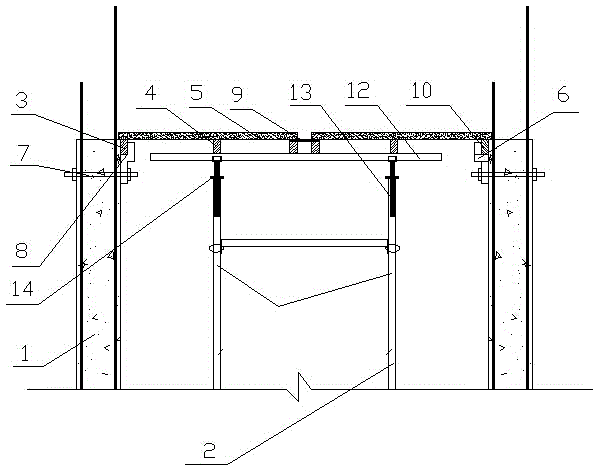

[0016] Such as figure 1 , 2 , 3, the present invention includes a four-sided shear wall body of wall 1, scaffolding 2, the first wooden frame 3, the second wooden frame 4 and two laminated panels 5.

[0017] The upper circumference of the inner wall of the four-sided shear wall body 1 is evenly distributed with Z-shaped fixing parts 6, and the lower part of the Z-shaped fixing parts 6 is attached to the body of the shear wall body 1, and passes through the body of the shear wall body 1. The wall screw 7 is fixed, the first U-shaped groove 8 is formed between the top of the Z-shaped fixture 6 and the wall 1, and the first U-shaped groove of a row of Z-shaped fixtures on the top of each shear wall wall 1 The first wooden frame 3 is clamped inside 8, and the first wooden frame 3 on the four-sided shear wall body 1 forms a rectangular frame 10, and the upper end surface of the first wooden frame 3 is flat with the upper end surface of the shear wall body 1 together.

[0018] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com