Patents

Literature

40results about How to "Installation quality is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

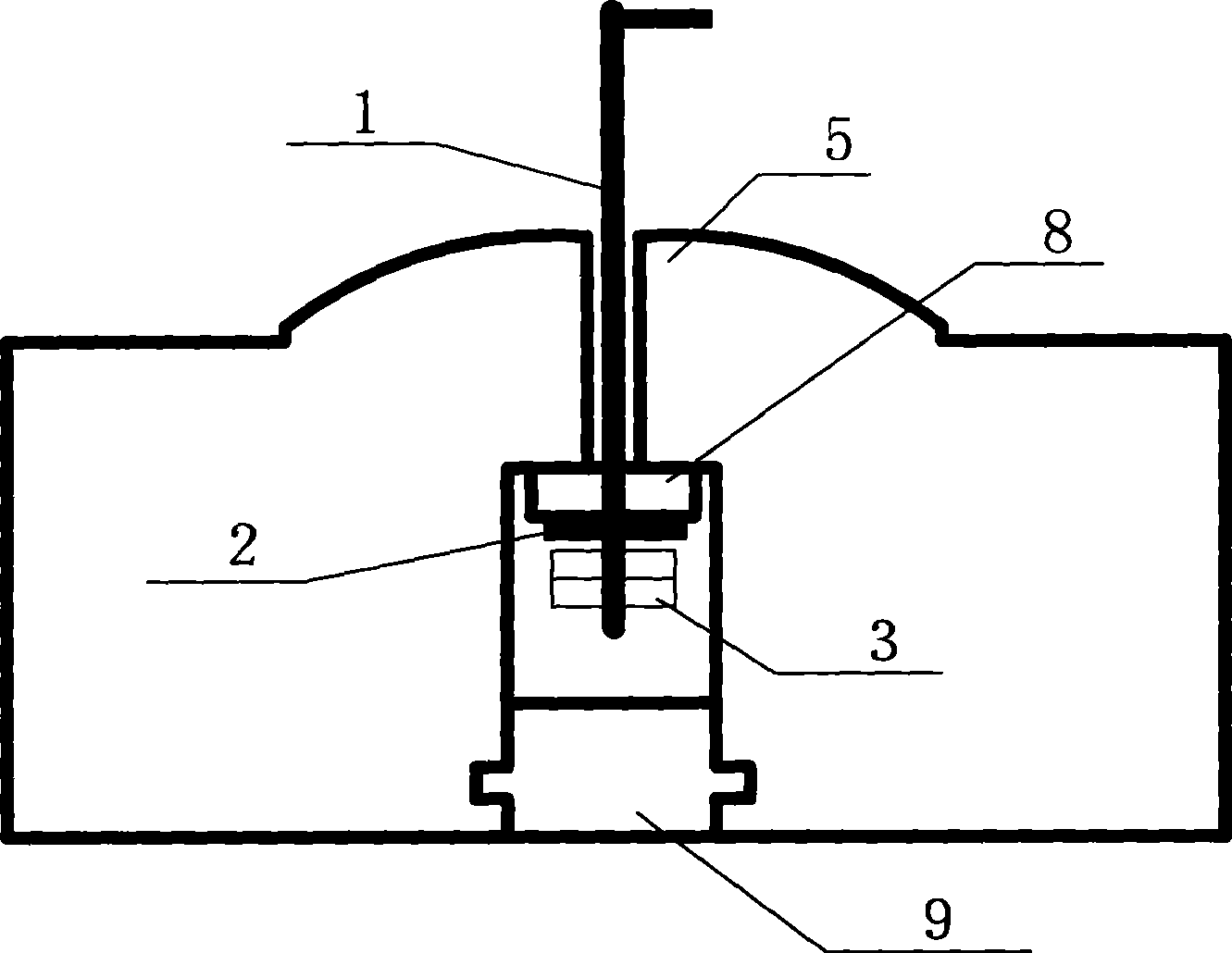

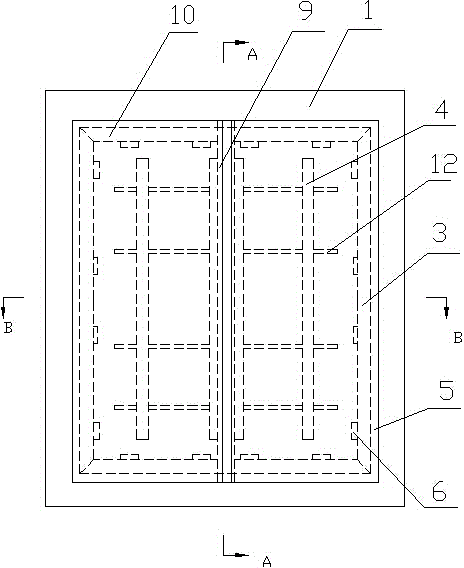

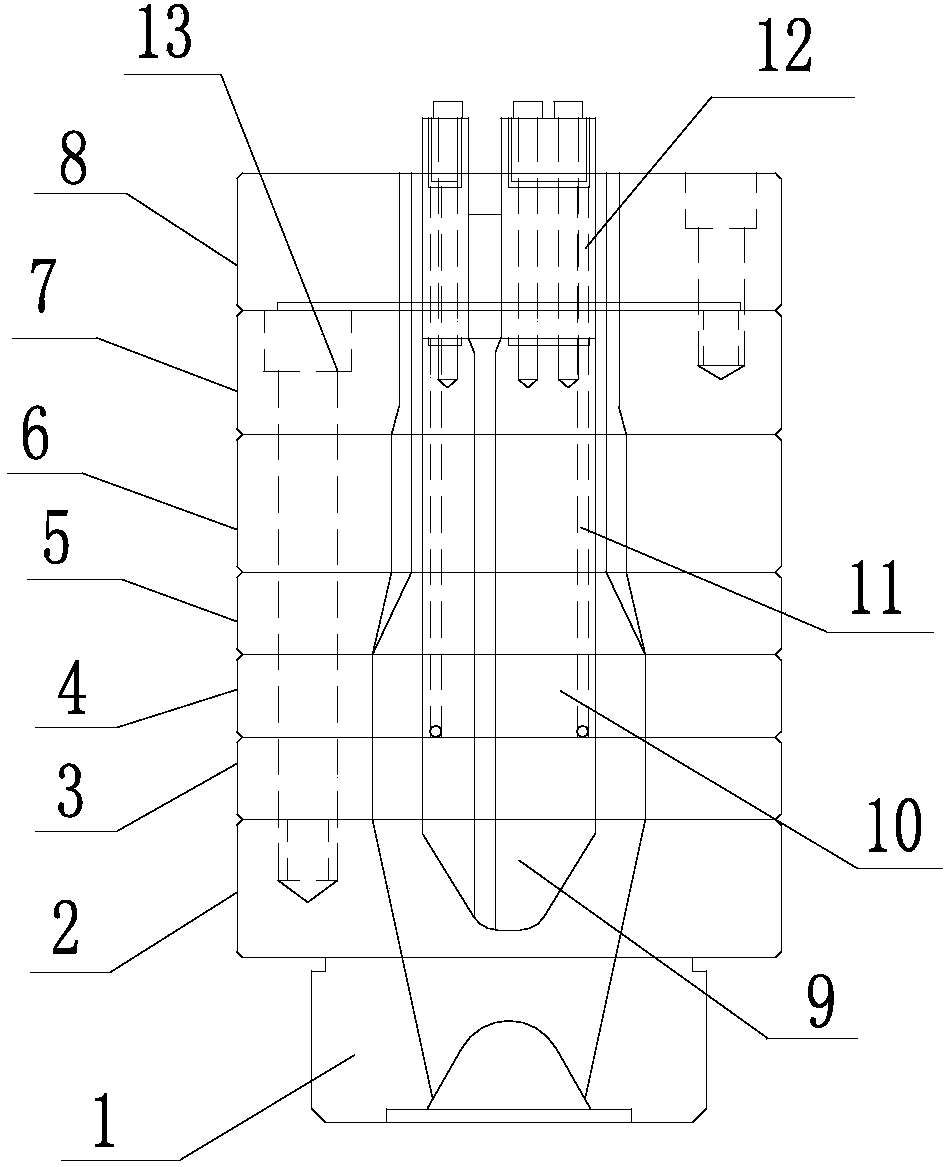

Filing layered sedimentation monitoring device and method

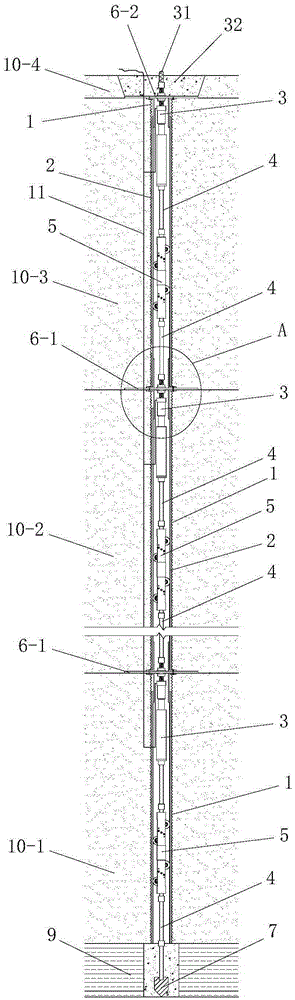

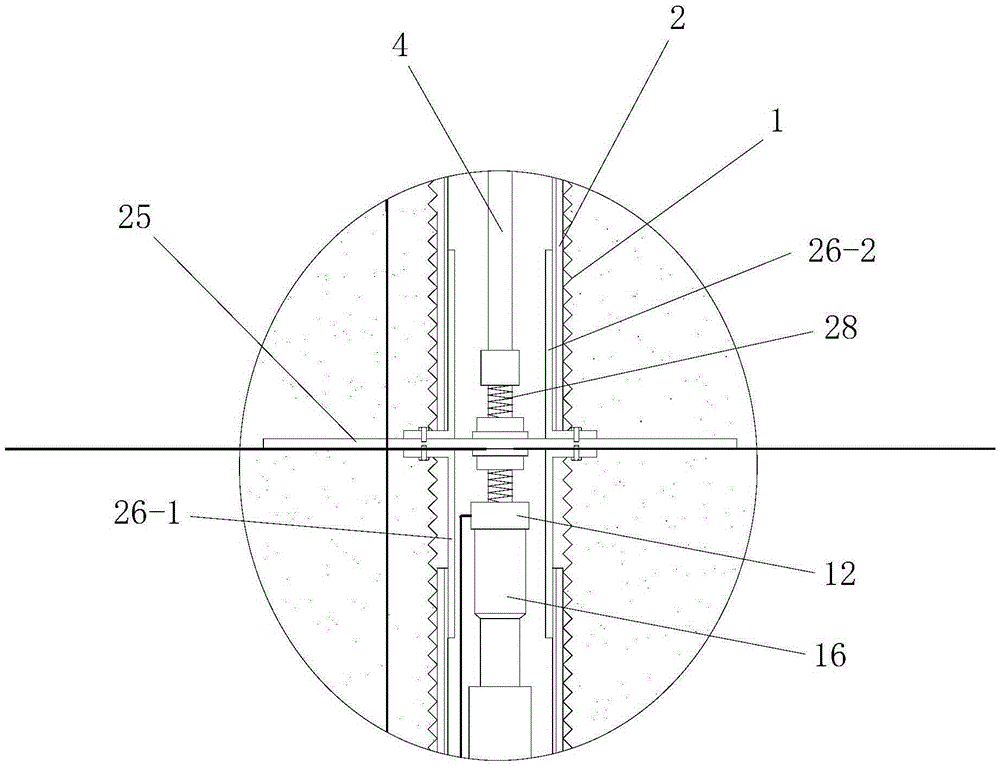

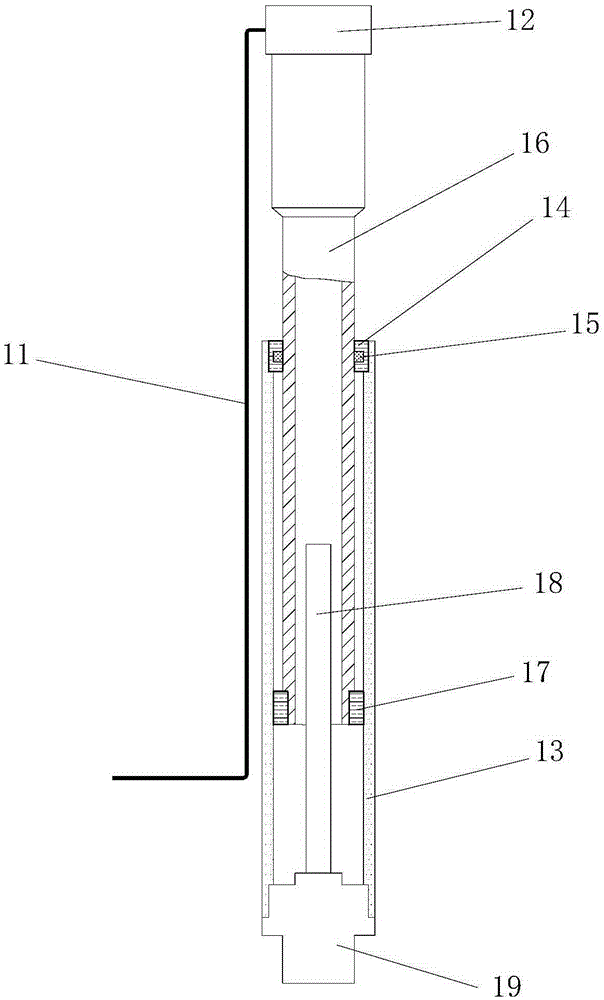

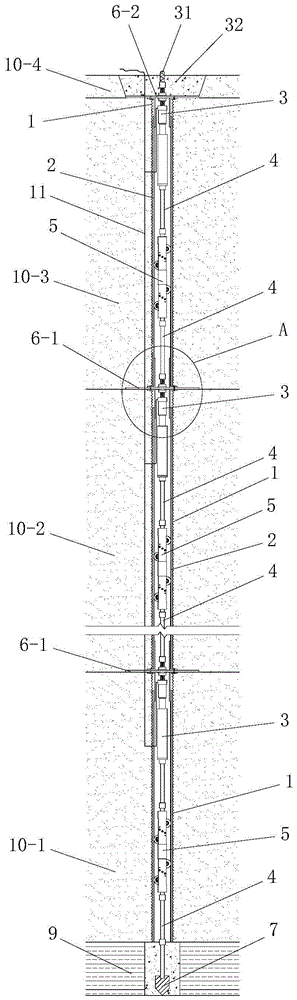

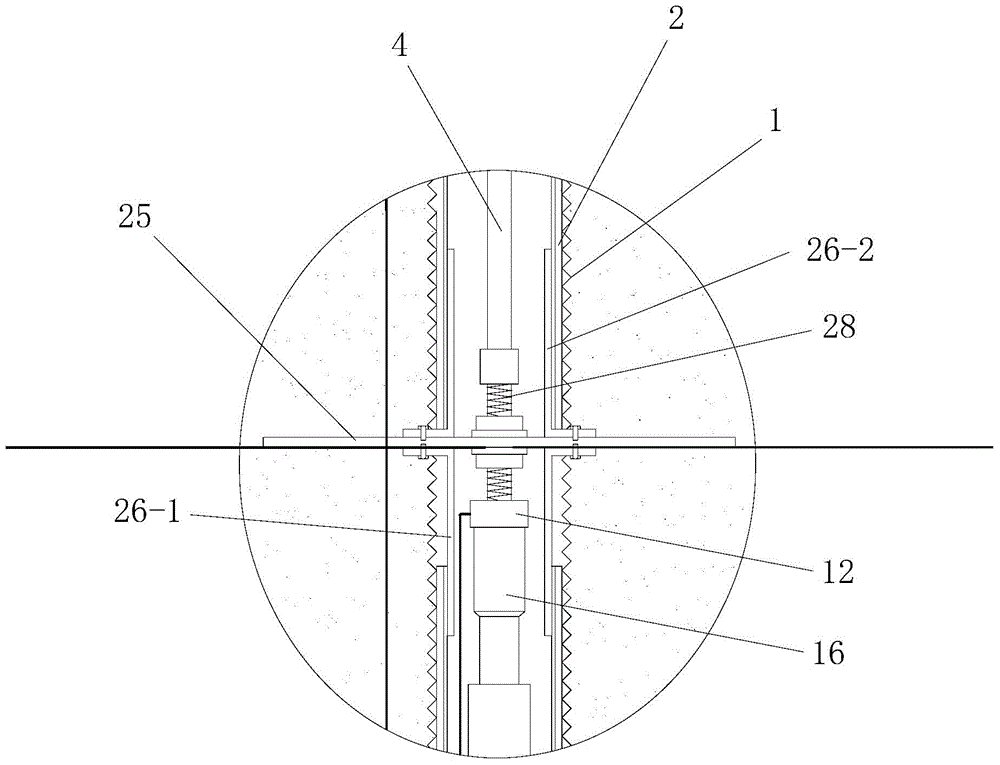

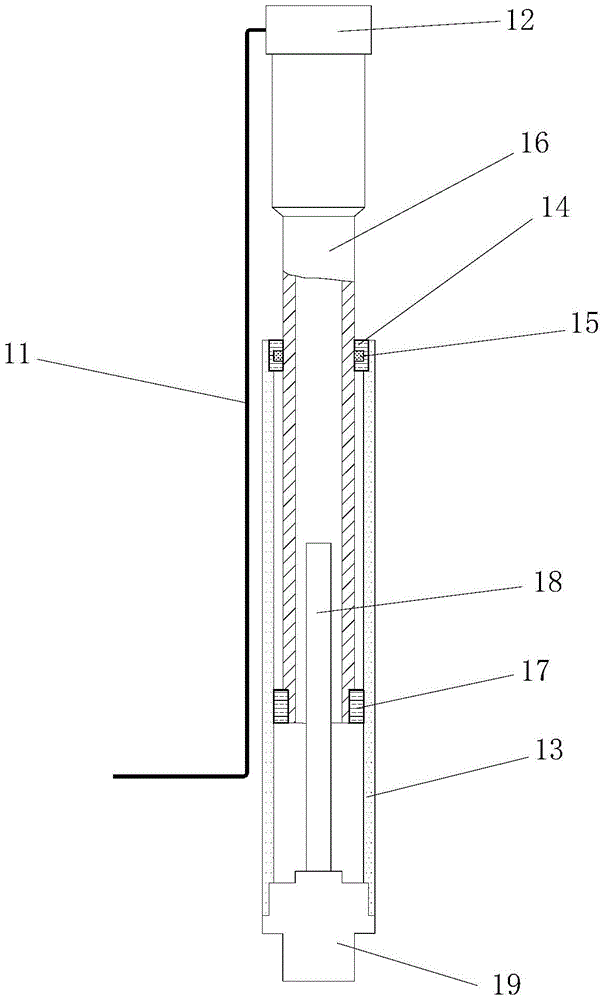

The invention discloses a filing layered sedimentation monitoring device and method. The monitoring device comprises a bottom sedimentation monitoring unit, a middle sedimentation monitoring unit and a ground surface sedimentation monitoring unit which are buried in a soil layer to be monitored from bottom to top and are vertically arranged. Burying holes are formed in the soil layer to be monitored. An anchoring head is arranged under the bottom sedimentation monitoring unit. The bottom sedimentation monitoring unit, the middle sedimentation monitoring unit and the ground surface sedimentation monitoring unit are all provided with inclinometer pipes, extensible pipes arranged on the outer sides of the inclinometer pipes in a sleeving mode and displacement sensors installed on the upper portions of the inner sides of the inclinometer pipes. The monitoring method comprises the steps that firstly, drilling of the burying holes is conducted; secondly, the bottom sedimentation monitoring unit is installed; thirdly, the middle sedimentation monitoring unit is installed; fourthly, the ground surface sedimentation monitoring unit is installed; and fifthly, layered sedimentation monitoring is conducted. The filing layered sedimentation monitoring device and method are reasonable in design, convenient and easy to operate, convenient to bury, high in measuring precision and capable of effectively solving the problems that existing layered sedimentation monitoring equipment is large in equipment burying workload and low in measuring precision.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

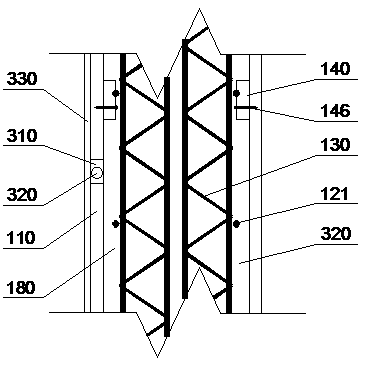

Concrete shear wall structure and wall internal pipeline separated construction method

ActiveCN111075062AInstallation quality is easy to controlStrict installation qualityWallsBuilding reinforcementsArchitectural engineeringMesh reinforcement

The invention relates to a concrete shear wall structure and wall internal pipeline separated construction method. The concrete shear wall structure and wall internal pipeline separated construction method comprises the steps of shear wall structure construction and wall internal pipeline construction, wherein in the shear wall structure construction, steel bar truss fixing formworks serve as shear wall formworks for pouring shear wall concrete, after the shear wall concrete is poured, face plates of the steel bar truss fixing formworks are solidified on the surface of a shear wall concrete layer and are not disassembled, and steel meshes and steel bar trusses in the steel bar truss fixing formworks are solidified in the shear wall concrete layer and form steel bars of the shear wall concrete layer; and in the wall internal pipeline construction, grooves for distributing pipelines are formed in the face plates of the surface of a shear wall body, the pipelines are distributed in the grooves, and the wall structure is not damaged. The concrete shear wall structure and wall internal pipeline separated construction method is beneficial to reduction of the work amount and labor intensity of construction, the degree of influences of human factors on building quality is reduced, construction cost is reduced, distribution of the pipelines in the wall is facilitated, and damage to thewall structure due to distribution of the pipelines is avoided.

Owner:ZHONGQINGDA TECH HLDG CO LTD +1

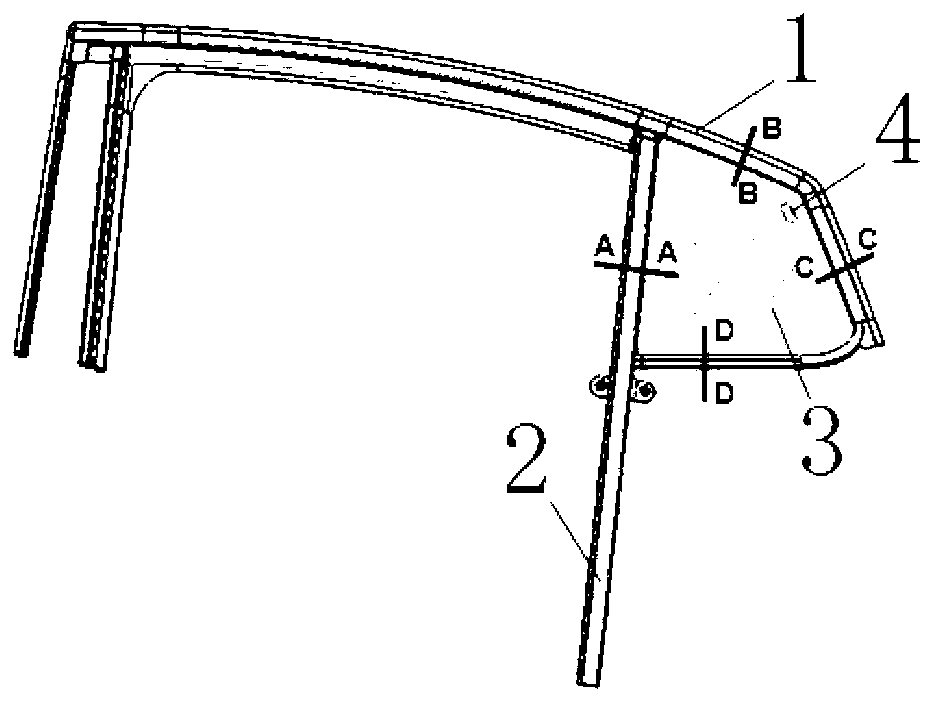

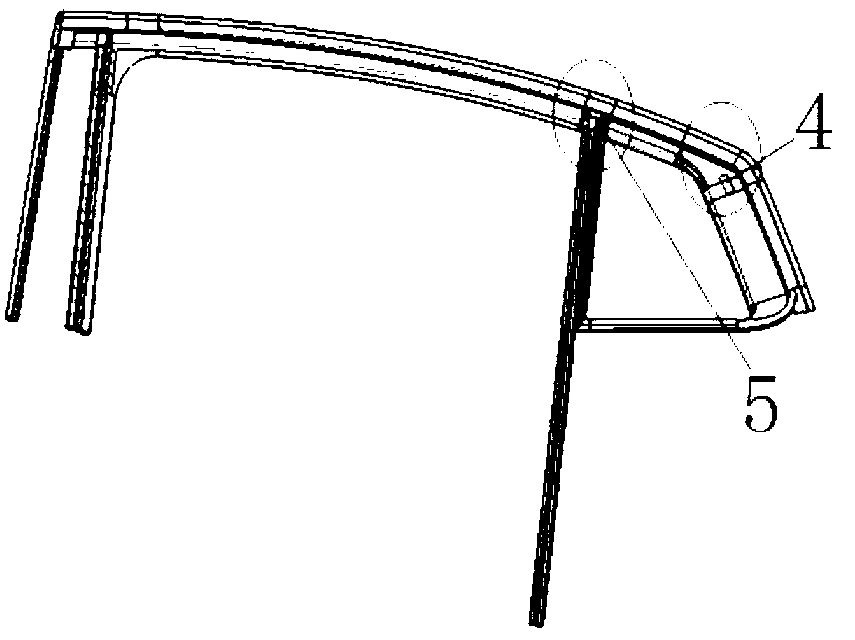

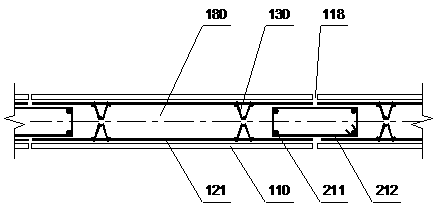

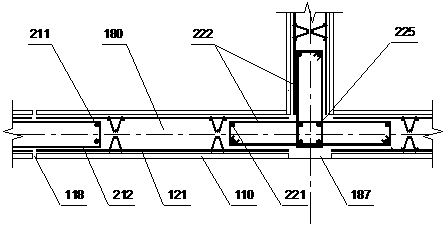

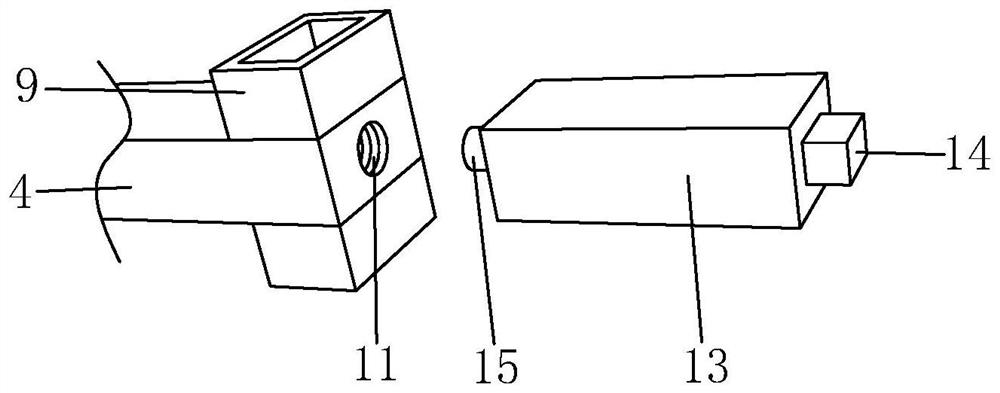

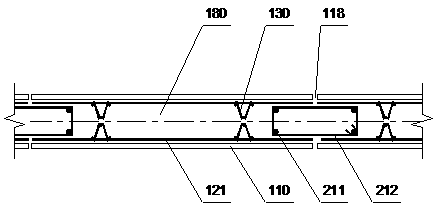

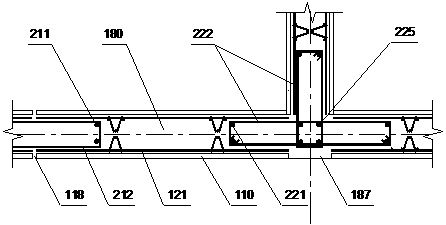

Split-type glass guide rail structure for car door and fixing method thereof

ActiveCN103253107AReduce scrap rateEasy assembly and clampingWindowsWindscreensRejection rateComputer engineering

The invention discloses a split-type glass guide rail structure for a car door and a fixing method thereof. The split-type glass guide rail structure comprises an upper glass guide groove and a back guide rail, wherein an inserting groove is formed in the upper glass guide groove, and the top end of the back guide rail penetrates through the inserting groove and is matched with a metal plate hole in a metal plate of the car door. The fixing method of the split-type glass guide rail structure for the car door includes the steps: firstly, installing four-corner window glass on the back guide rail; installing the back guide rail and the four-corner window glass on the upper glass guide groove, wherein the back guide rail and the four-corner window glass are installed together; finally, clamping the back guide rail, the four-corner window glass and the upper glass guide groove together on the metal plate of the car door. The split-type structure of the upper glass guide groove, the back guide rail and the four-corner window glass of the car door is easy and convenient to assemble and clamp, installing quality is convenient to control, good appearance is guaranteed, parts are manufactured in a separated mode, precision is convenient to control, a rejection rate of finished products is reduced, and cost is low.

Owner:CHERY AUTOMOBILE CO LTD

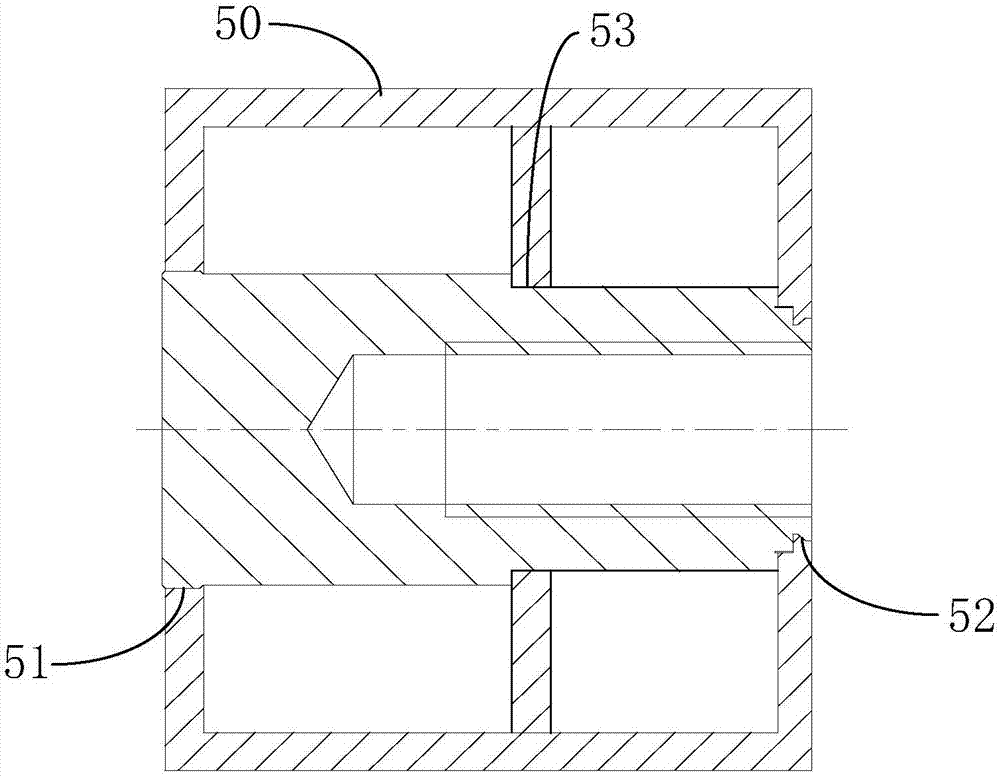

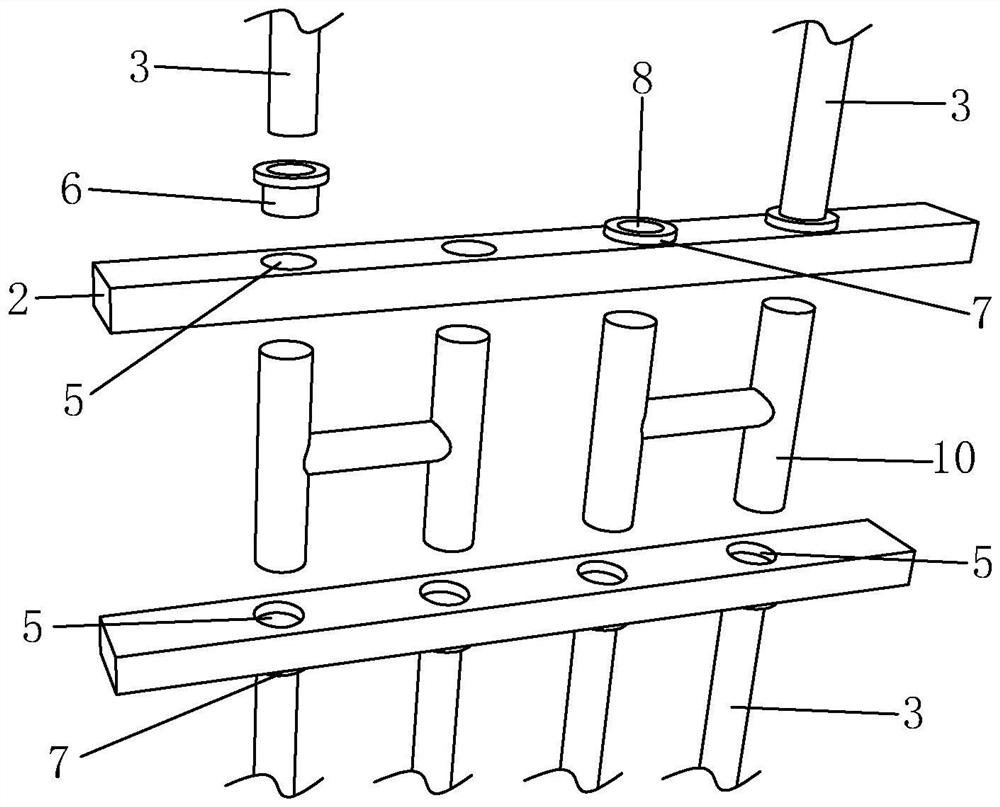

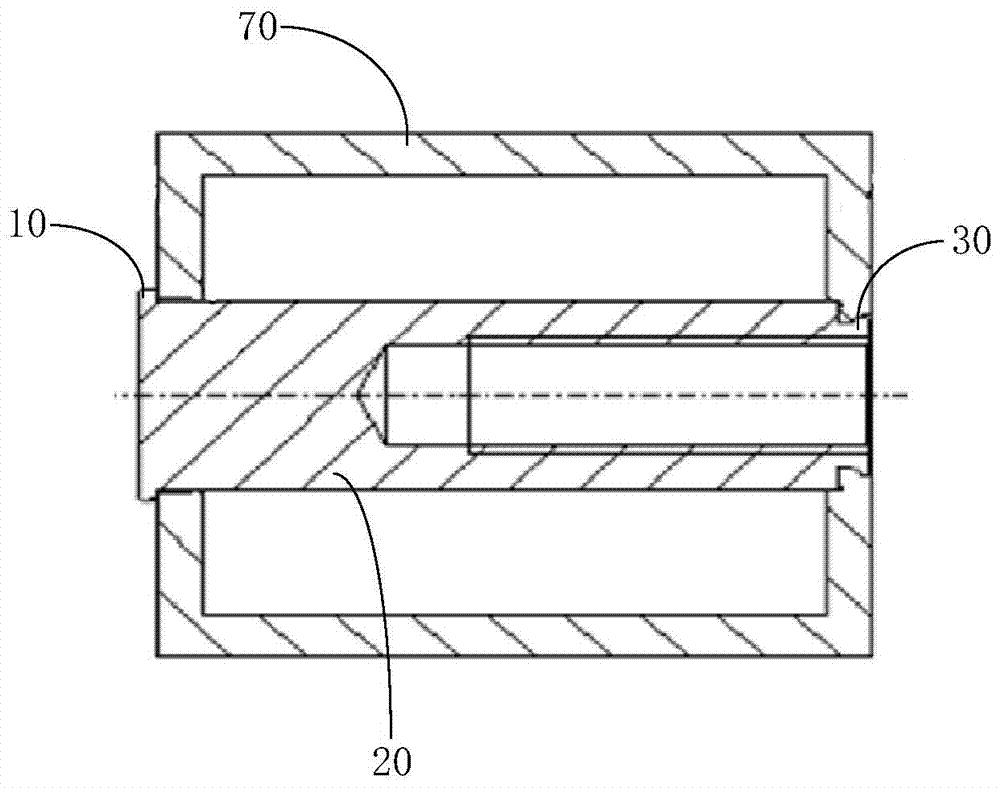

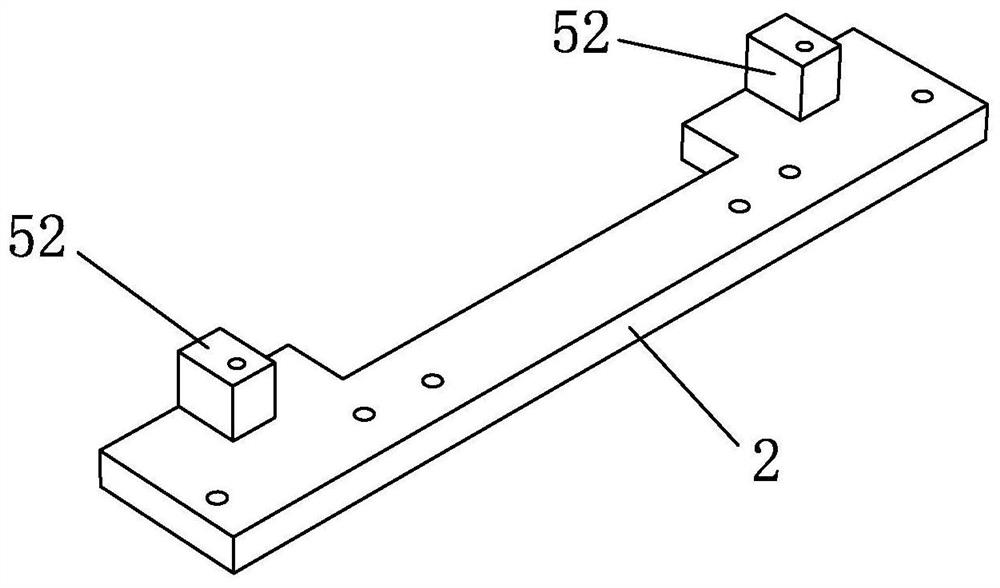

Profile material reinforcement connecting structure part

ActiveCN106907567AFirmly connectedEasy to installElongated constructional elementsShrinkage connectionsInterference fitEngineering

The invention relates to a profile material reinforcement connecting structure part used for fastening connection of profile materials with at least two parallel vertical surfaces. The profile material reinforcement connecting structure part comprises a barrel. First teeth arranged in the peripheral direction of the outer surface of the barrel are arranged at one end of the barrel. Interlocking keys arranged in the peripheral direction are arranged at the other end of the barrel. The first teeth and the interlocking keys are fixedly connected with the two parallel vertical surfaces of the profile materials correspondingly. At least one of the two ends of the barrel is fixedly connected with a matched fitting through a connector. According to the profile material reinforcement connecting structure part, the first teeth are in interference fit connection with one vertical surface of the profile materials, the interlocking keys achieve self-fastening with the other vertical surface of the profile materials through flowing of materials, fastening connection of the profile materials is realized through the structure part, and no special requirements exist for the wall thickness, width and tolerance of the profile materials. Installation is convenient, welding and re-tapping are not needed, and the cost and energy consumption are lowered. The two vertical surfaces of the profile materials are connected at the same time, the connecting reliability is increased, the barrel can serve as a reinforcement bar, and therefore the rigidity of the profile materials is increased.

Owner:PEM CHINA

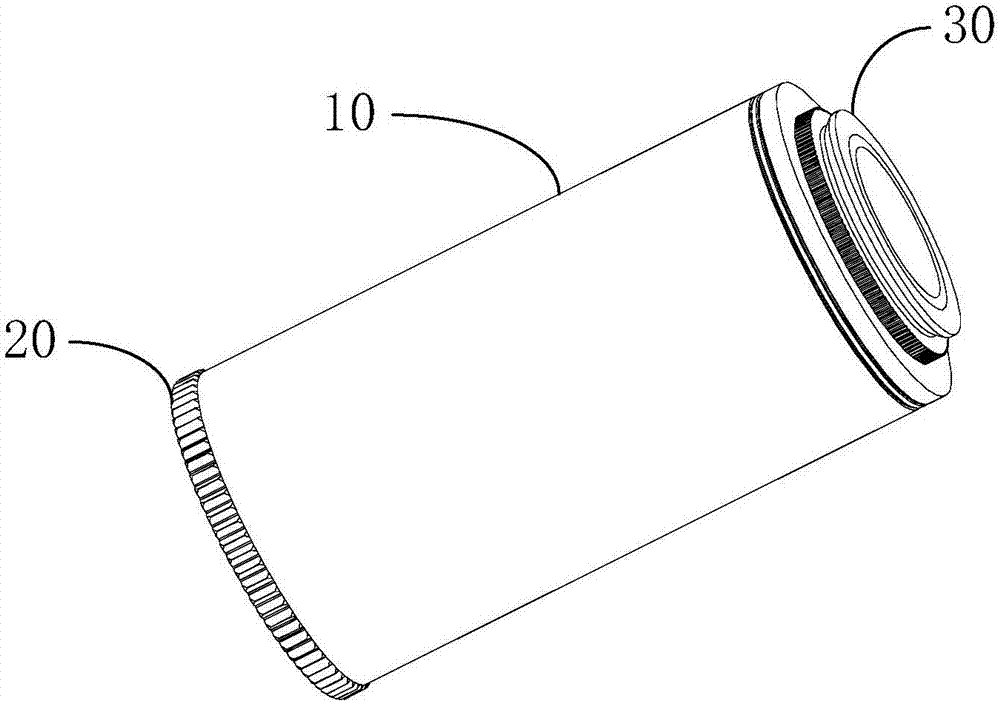

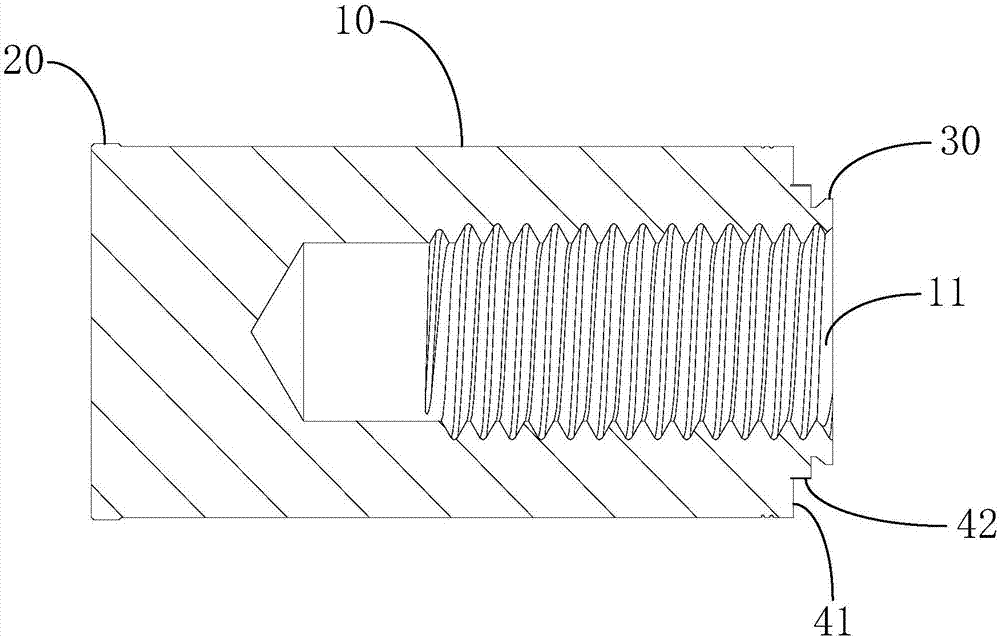

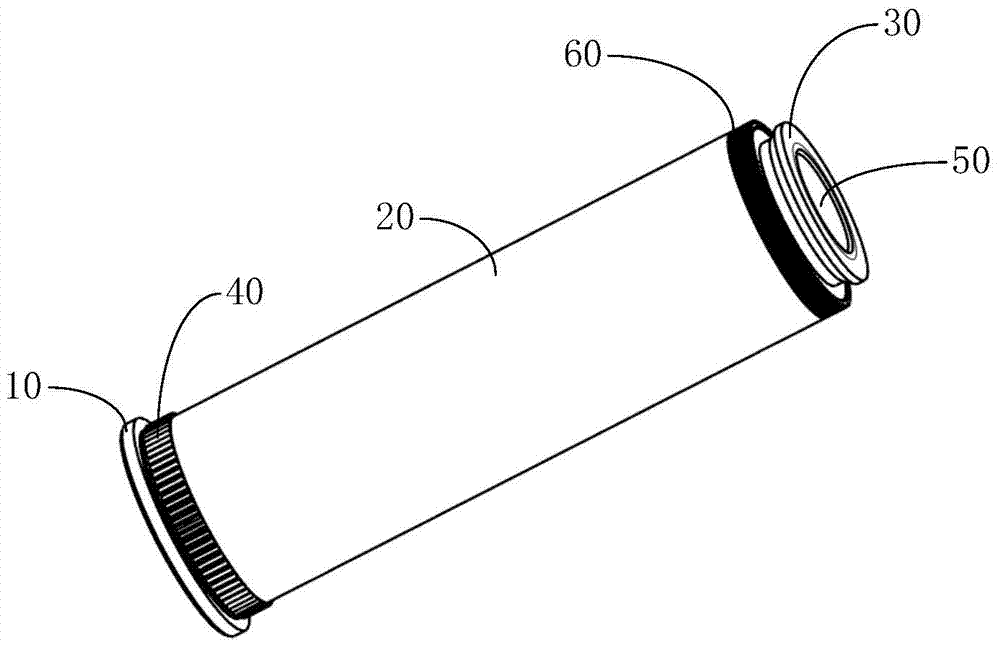

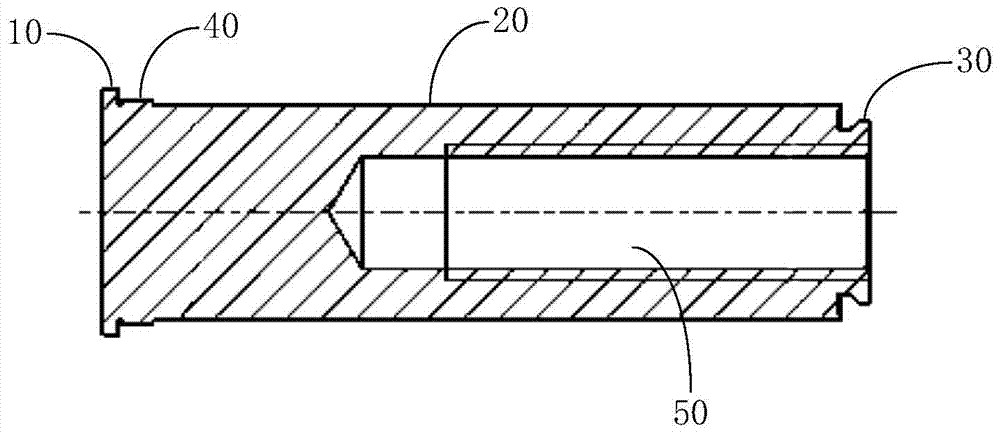

Sleeve nut, fastener and installation method of fastener

The invention relates to a sleeve nut, a fastener and an installation method of the fastener. The sleeve nut comprises a base, a sleeve and an interlocking key, wherein the base, the sleeve and the interlocking key are sequentially arranged. The outer diameter of the base is larger than that of the sleeve, and a circumferentially-arranged first knurled gear is arranged at the end, close to the base, of the sleeve. A through hole is formed inside the sleeve, or a threaded hole is formed in the side, close to the interlocking key, of the interior of the sleeve. According to the sleeve nut, as the end provided with the base is connected with a section in an interference fitting mode through the first knurled gear, and the end provided with the interlocking key is buckled to the section through flowing of a material, the sleeve nut is connected with the section in a fastened mode, no requirement for the wall thickness of the section exists, welding and re-tapping are not required, and cost and energy consumption are reduced.

Owner:PEM CHINA

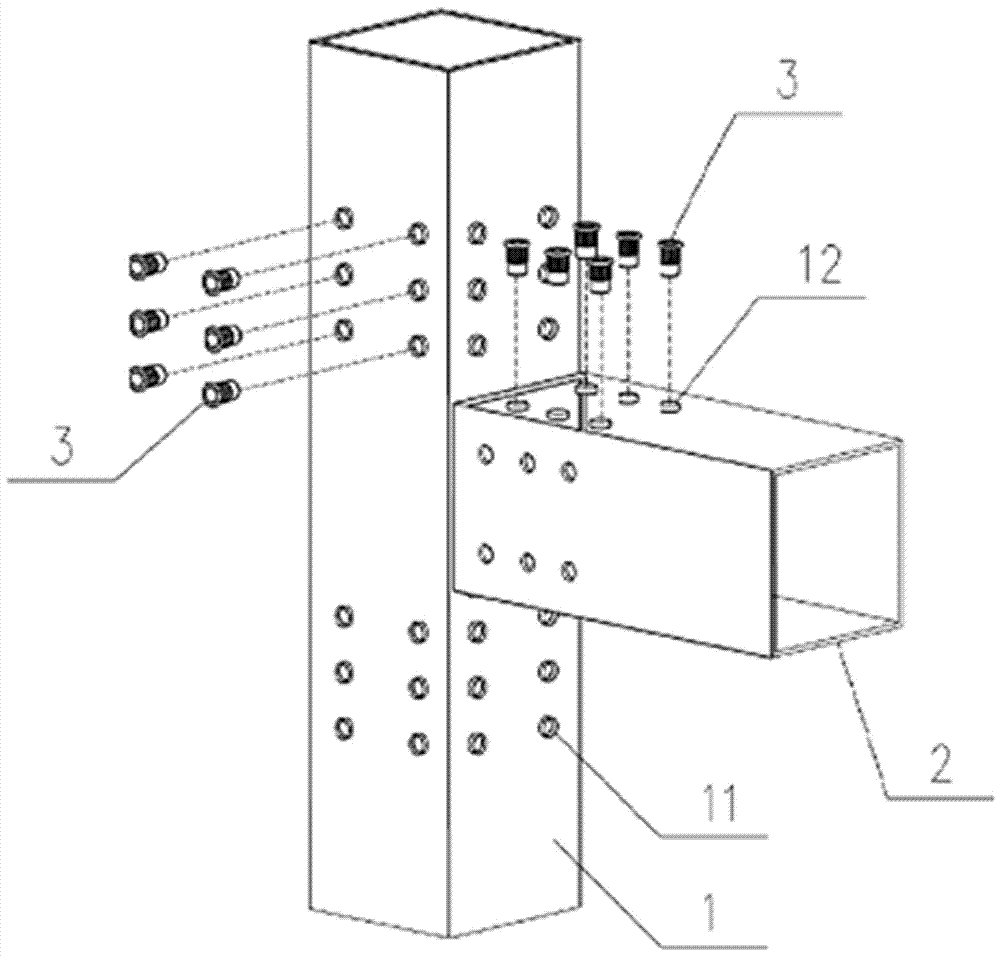

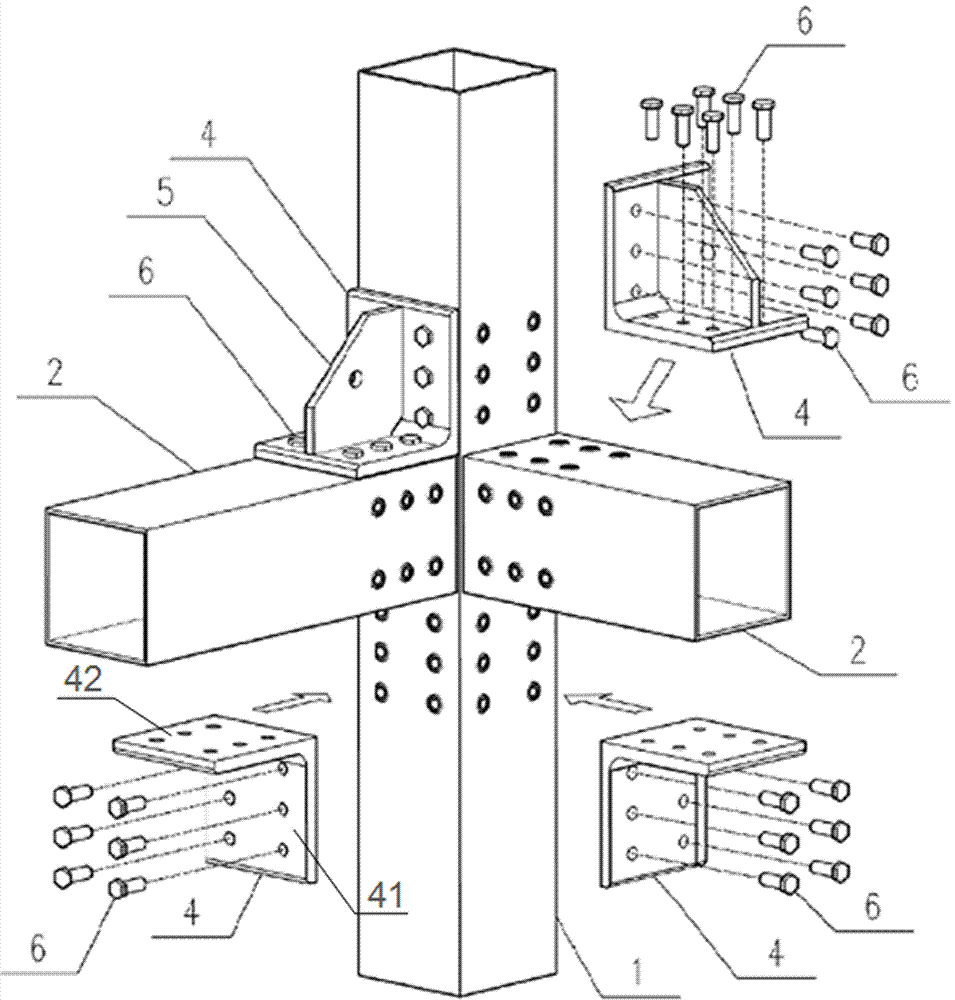

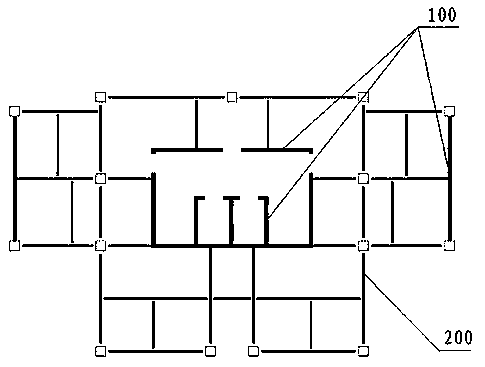

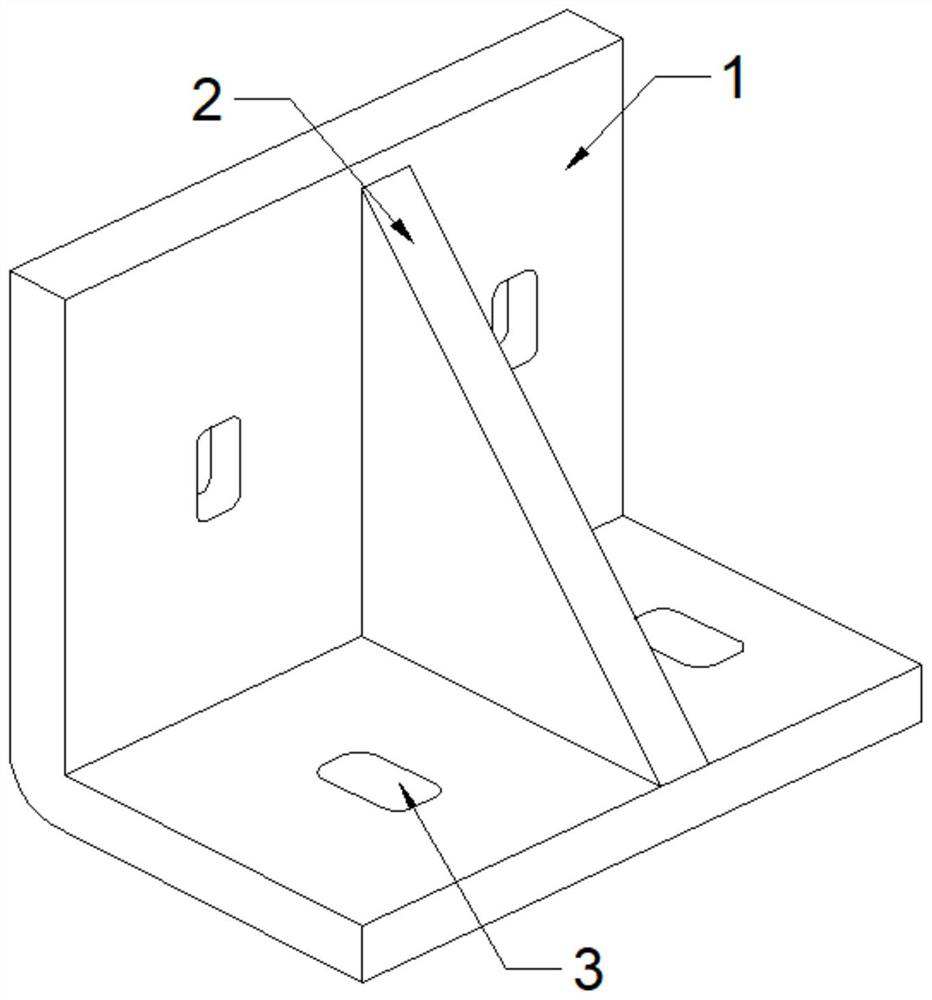

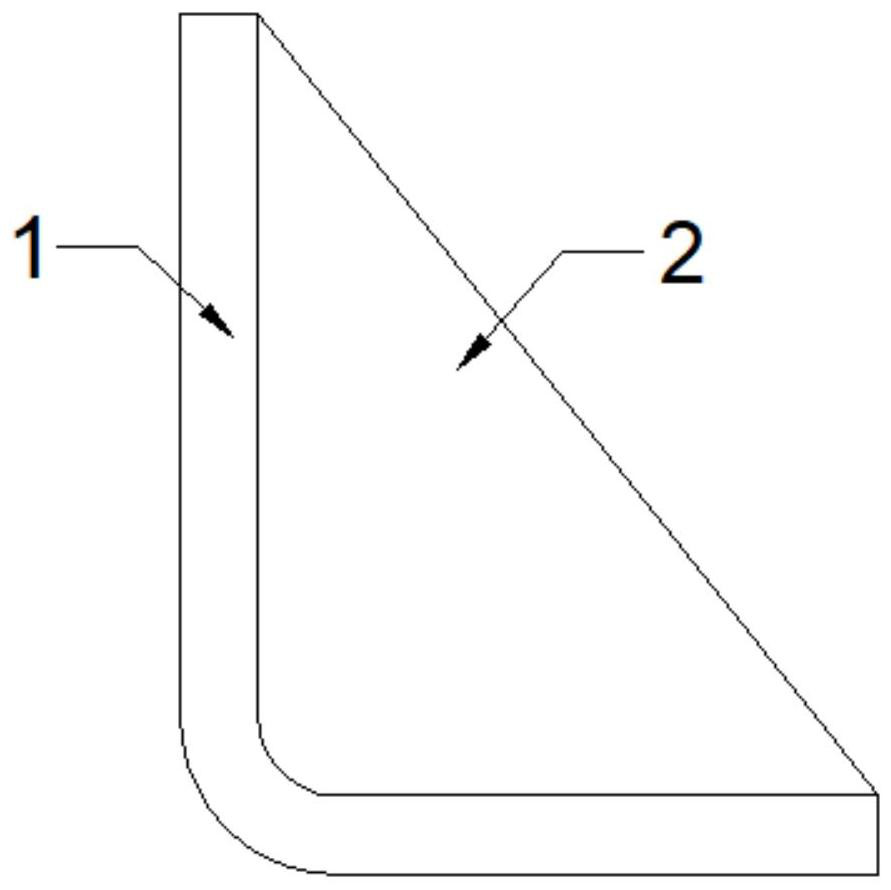

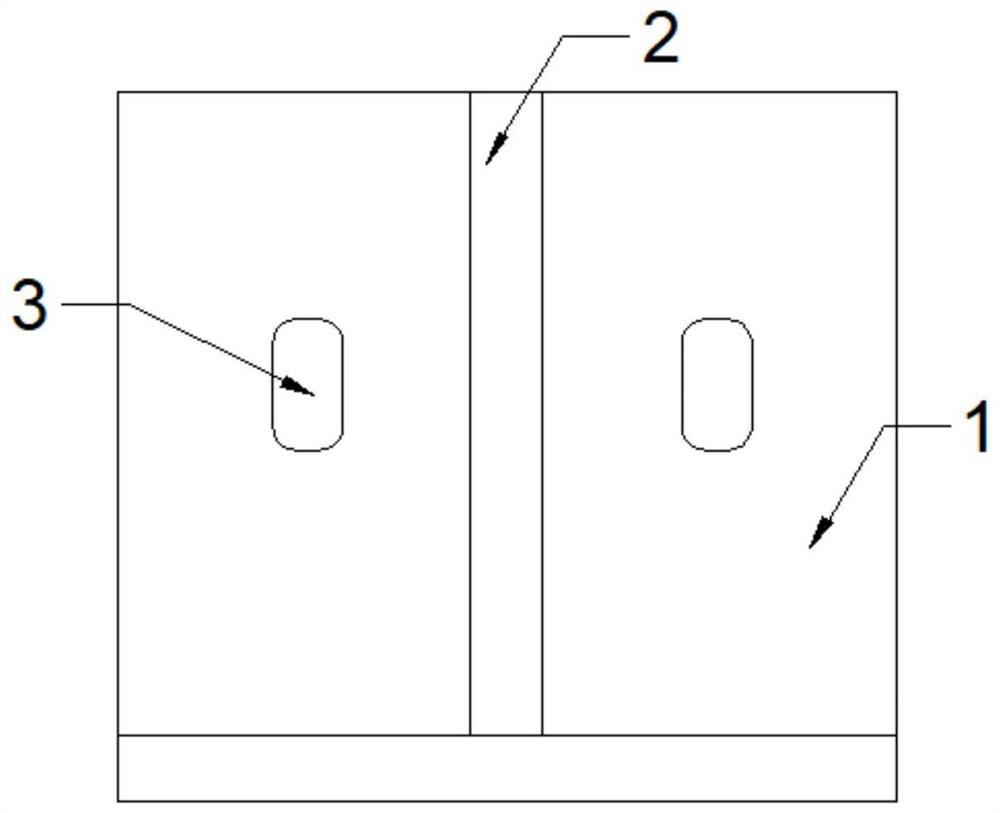

Modular building connection structure

PendingCN107503437AFor later reuseSimple construction methodBuilding constructionsConstruction engineeringSteel columns

A modular building connecting structure comprises a plurality of steel columns, a plurality of steel beams and a plurality of connecting steel angles; a plurality of fastening components are arranged in steel column connection holes and steel angle connection holes respectively and in steam beam connection holes and steel angle connection holes respectively and used for fixing the steel columns and steel beams through the cooperation of the connecting steel angles. Workers on site have no need to use rulers for measurement, the structure is not affected by the structural system installation accuracy, no welding is needed, no special installation tools are needed, the construction method is simple, the installation quality in the installation process is controllable, the connection strength is high, the installation accuracy is high, late maintenance and dismantling are convenient to conduct, later use of column and beam components is easily achieved, meanwhile the structure comprehensively exceeds existing connection modes in the market in the aspects that the installation cost is saved and the site construction efficiency is improved, and the structure has unique superiority.

Owner:USAS BUILDING SYST SHANGHAI

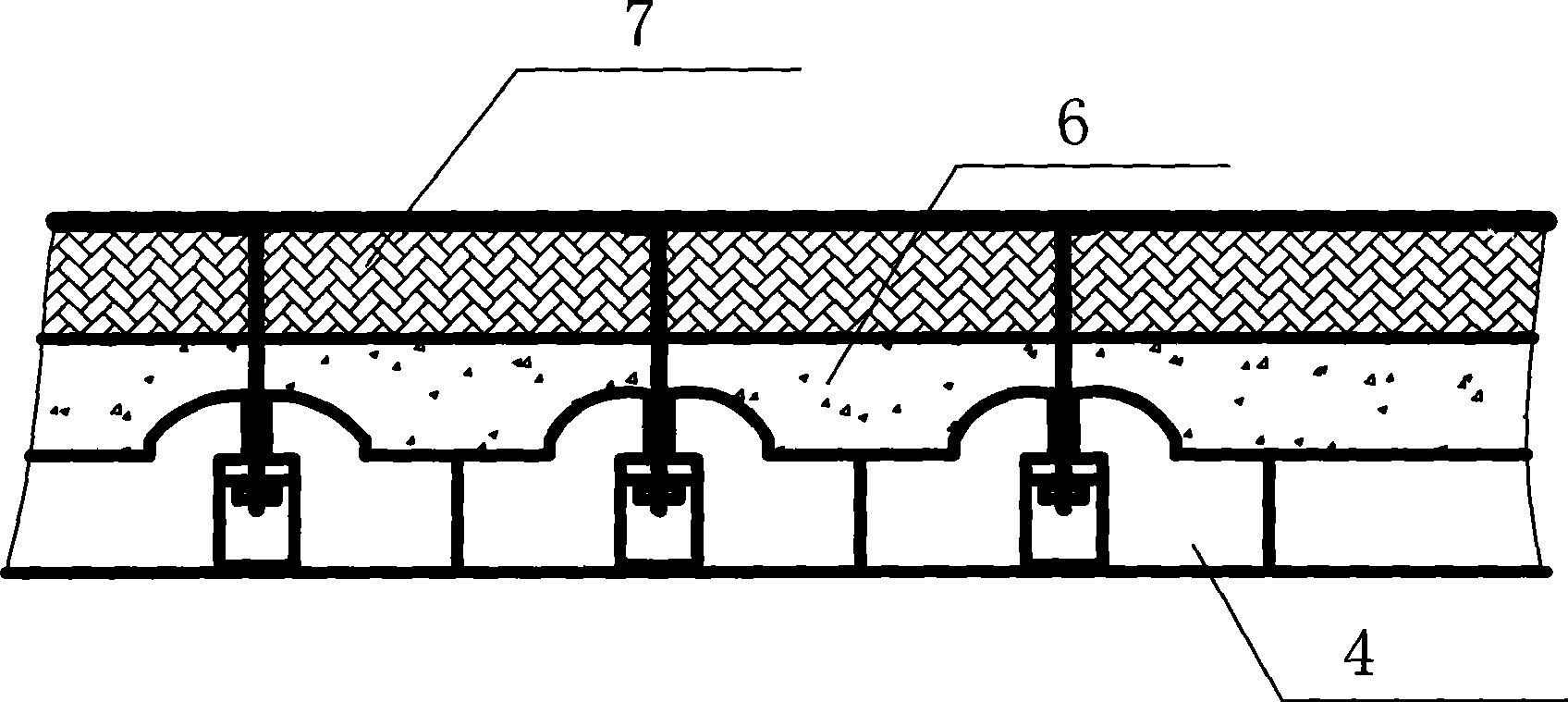

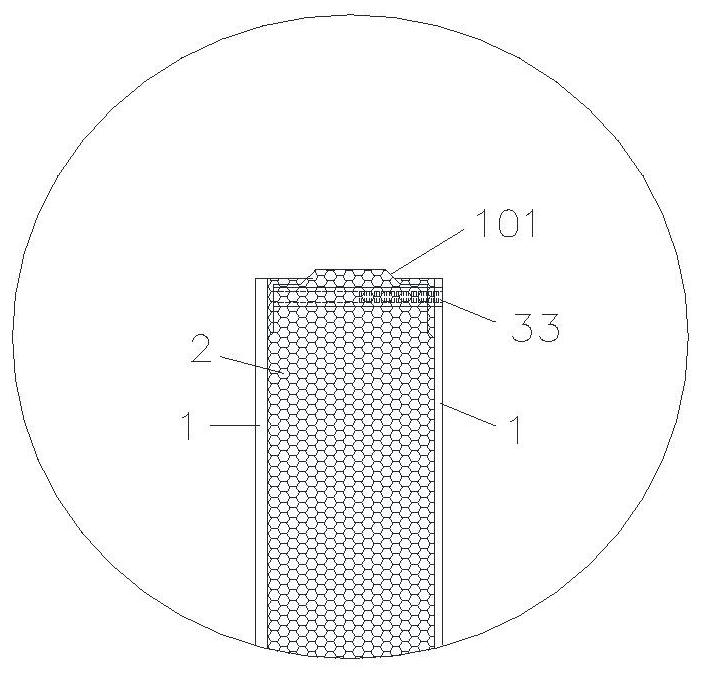

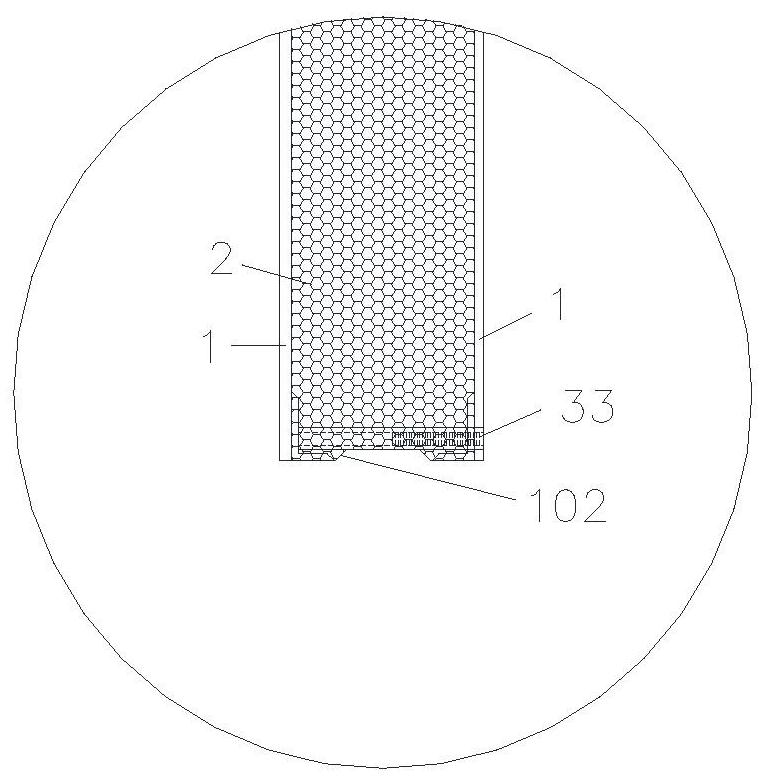

Fire-resistant abrasion-proof inner lining structure for heat insulation surface of industrial furnace

InactiveCN101504250AQuality controllableInstallation quality is easy to controlLinings repairRefractory wearFiber

The invention discloses a refractory wear-resistant lining structure for the thermal insulation surface of an industrial furnace, which comprises a heat resistant bolt, a heat resistant flat cushion, a heat resistant nut and a refractory wear-resistant brick; the refractory and wear-resistant brick is prefabricated for forming; the inside of the refractory wear-resistant brick is provided with a stepped through hole vertically; the fastening end of the heat resistant bolt passes through the wall body of the industrial furnace or a heat insulation casting material and a ceramic fiber brick on the furnace top, and is welded onto a steel plate on the wall body or a steel frame on the furnace top; and the thread end of the heat resistant bolt passes through the stepped through hole of the refractory wear-resistant brick, is arranged into the heat resistant flat cushion and is locked by the heat resistant nut. The refractory wear-resistant lining structure is a novel structure for replacing the prior industrial furnace, in particular the wall body and the furnace top on the heat insulation surface of a circulating fluidized bed boiler. The invention adopts a fixed module type refractory wear-resistant brick structure; because the refractory wear-resistant brick is manufactured by a factory, the refractory wear-resistant brick is not limited by the site construction condition and has easy control in quality, convenient mass production, and small quality difference; and the refractory wear-resistant lining structure has convenient site construction, simple mounting and easy control of mounting quality, and also brings great convenience to overhauling.

Owner:宜兴市张泽耐火电瓷厂有限公司

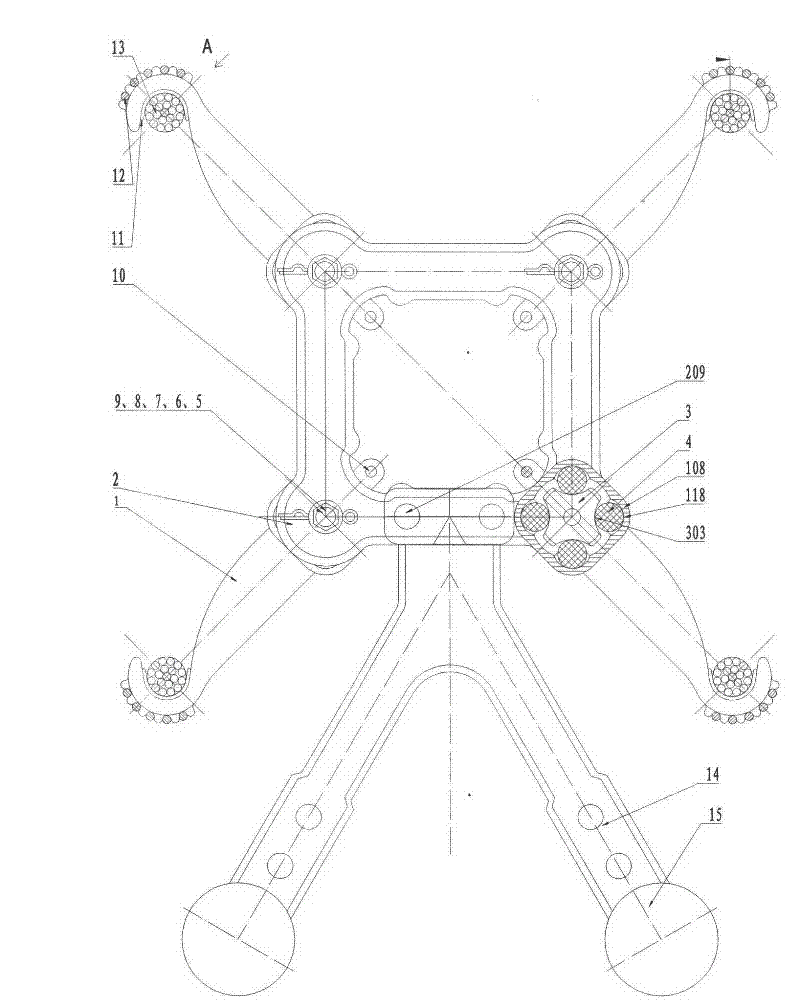

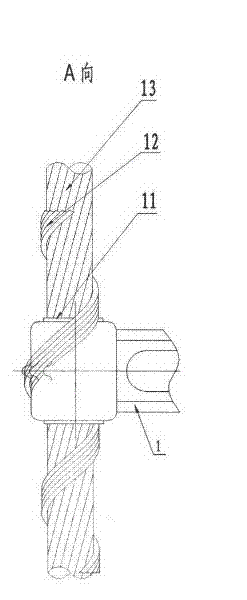

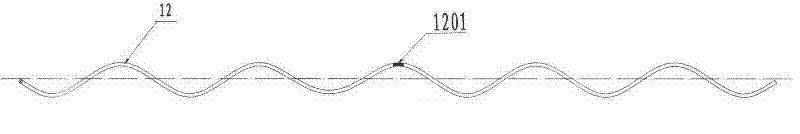

A pre-twisted anti-galling damping spacer

InactiveCN102290764APrevent axial displacementPrevent cascadingMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsYarnEngineering

The invention relates to a pre-twisted anti-slip anti-dancing damping spacer. It includes a bracket and a wire clip, the wire clip is arranged at the end corner of the bracket for connecting the split wire, and the wire clip also includes a pre-twisted wire; the head end of the wire clip used to connect the split wire is hook-shaped, The back of the hook is provided with a positioning structure for positioning the pre-twisted wire; the tail end of the clamp is connected to the end corner of the bracket through a damping and limiting device; the lower part of the middle of the bracket is fixed Connect the herringbone pendulum device; the herringbone pendulum device includes a herringbone frame plate and a spherical pendulum, the top of the herringbone frame plate is fixedly connected to the lower frame in the middle of the bracket, the spherical The pendulum is fixedly connected to the ends of the two feet of the herringbone frame plate. The method of connecting the split wires of the present invention is improved to a pre-twisted wire connection method with a limit structure, which can be installed by hand, is convenient to install, has good reliability, and is easy to control the installation quality.

Owner:江苏华厦电力成套设备有限公司

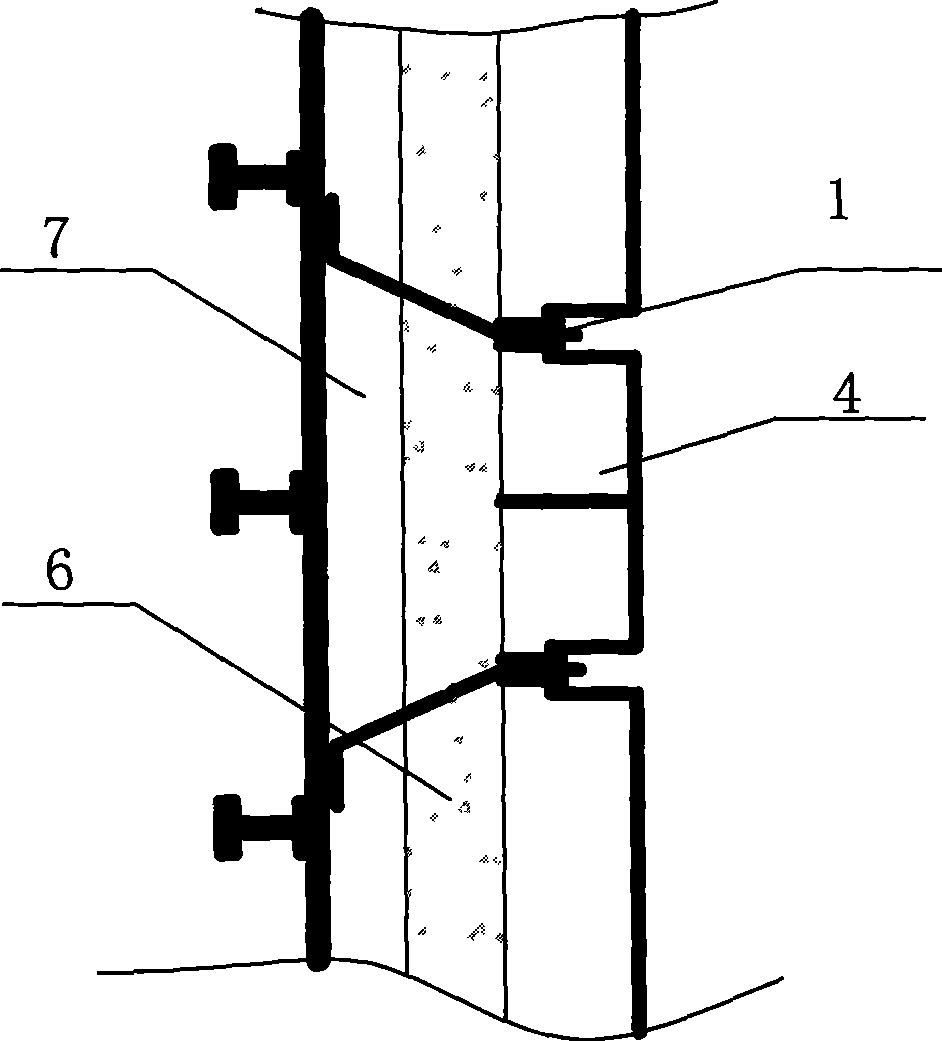

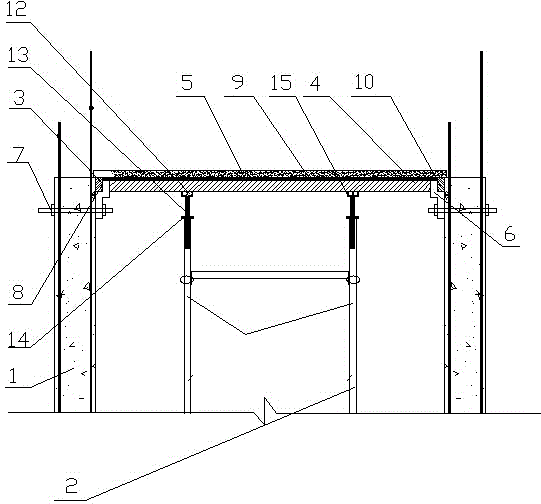

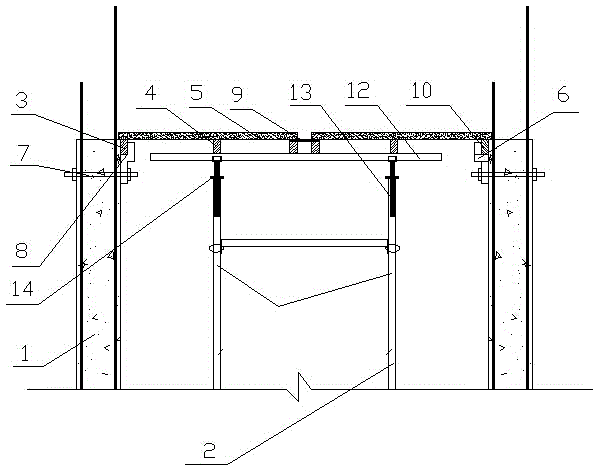

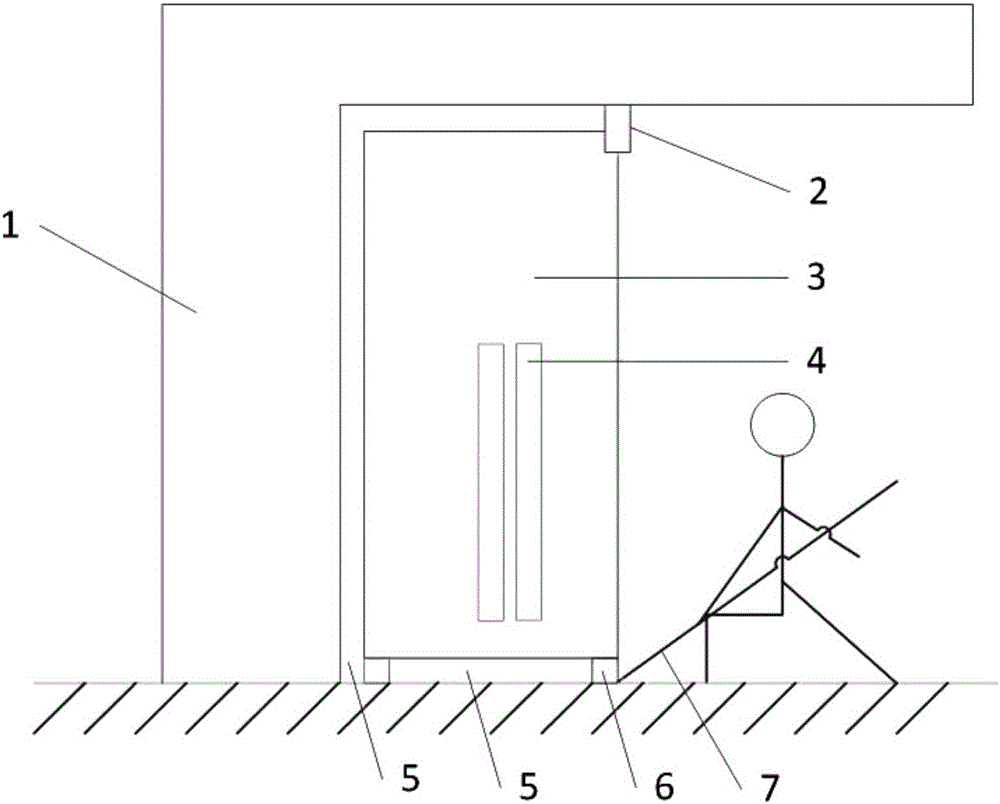

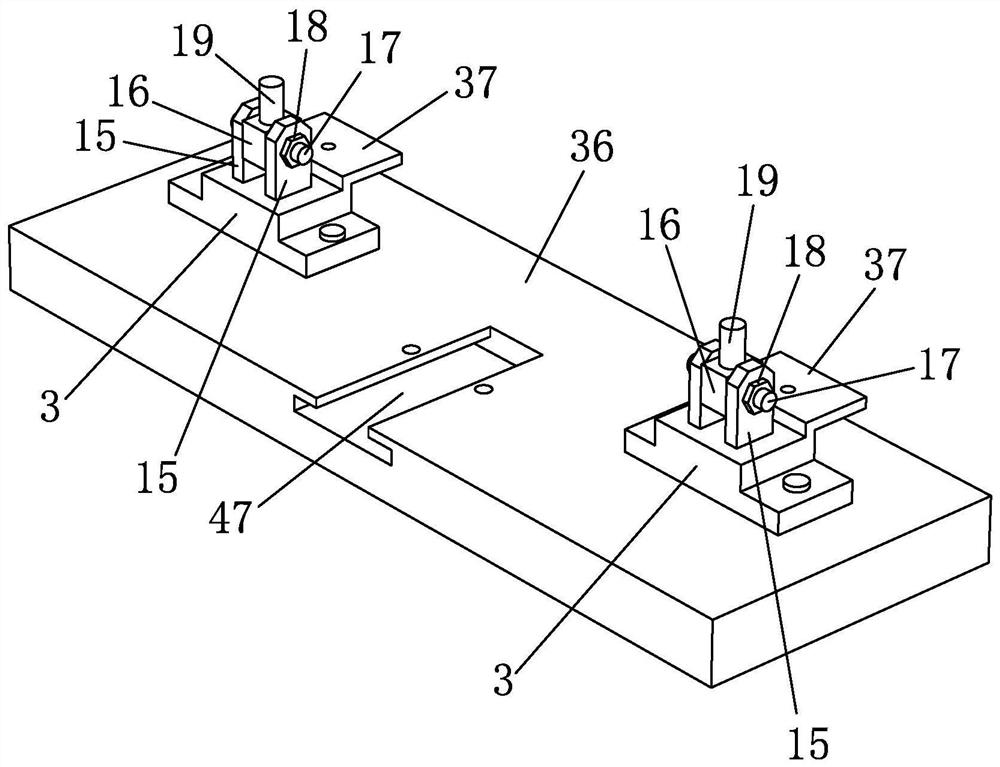

Supporting system of pre-stressed concrete laminated slab of shear wall structure

InactiveCN105275202AInstallation quality is easy to controlClear forceForms/shuttering/falseworksSupporting systemPre stress

A supporting system of a pre-stressed concrete laminated slab of a shear wall structure belongs to the field of building construction and comprises a quadruple shear wall body, a first wood brace, a second wood brace and a laminated slab, wherein Z-shaped fixation parts are arranged uniformly on the upper annular circumference on the inner wall of the quadruple shear wall body, the lower part of the Z-shaped fixation part is fixed on the shear wall body, an U-shaped groove is formed between the upper part of the Z-shaped fixation part and the wall part, and the first wood brace is respectively clamped in the U-shaped groove of the row of Z-shaped fixation parts on the upper part of each shear wall body. The supporting system of the pre-stressed concrete laminated slab of the shear wall structure provided by the invention is beneficial in that (1) construction operations of this invention are simple and convenient and can guarantee a construction period; (2) installation quality of the laminated slab can be controlled easily, and evenness can be guaranteed; and (3) the laminated slab provided by the invention is definite in load carrying, safe and reliable, and eliminates safety hidden dangers of template frame collapse with a traditional manner.

Owner:JIANGSU HUAJIANG CONSTR GROUP

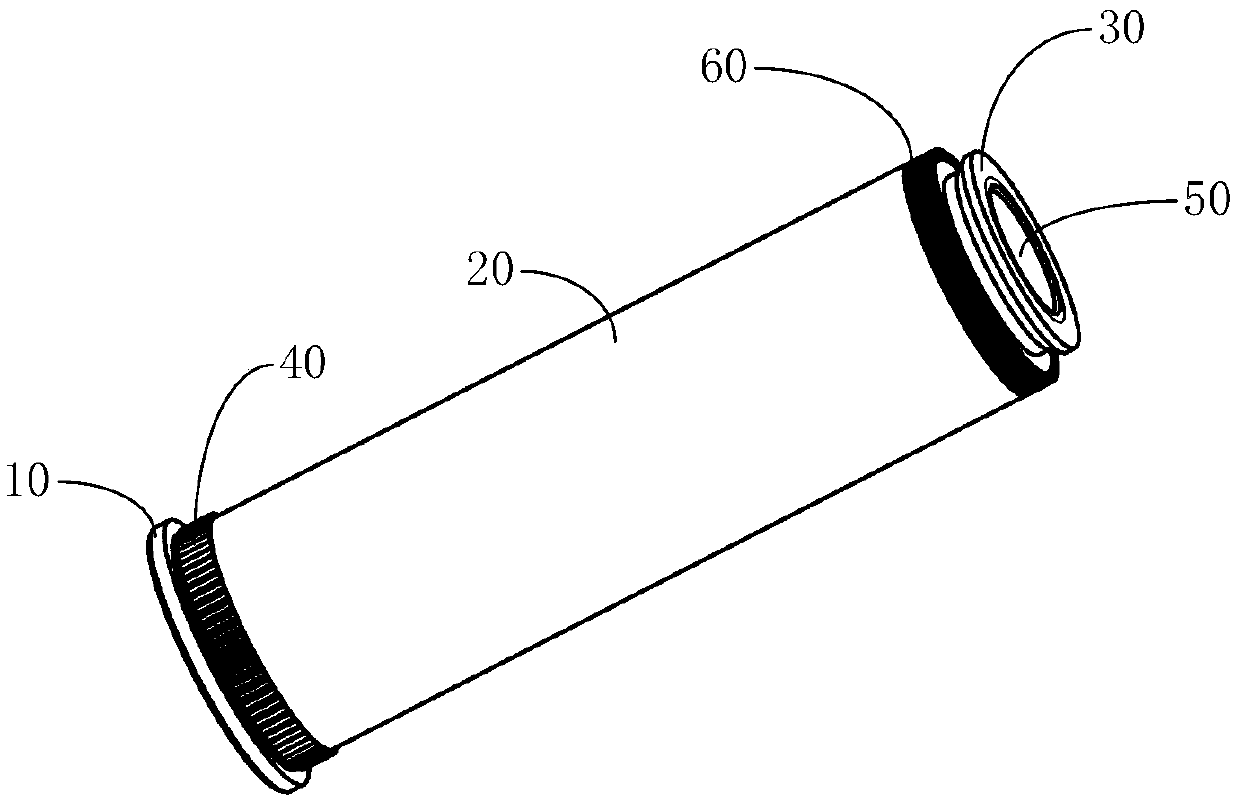

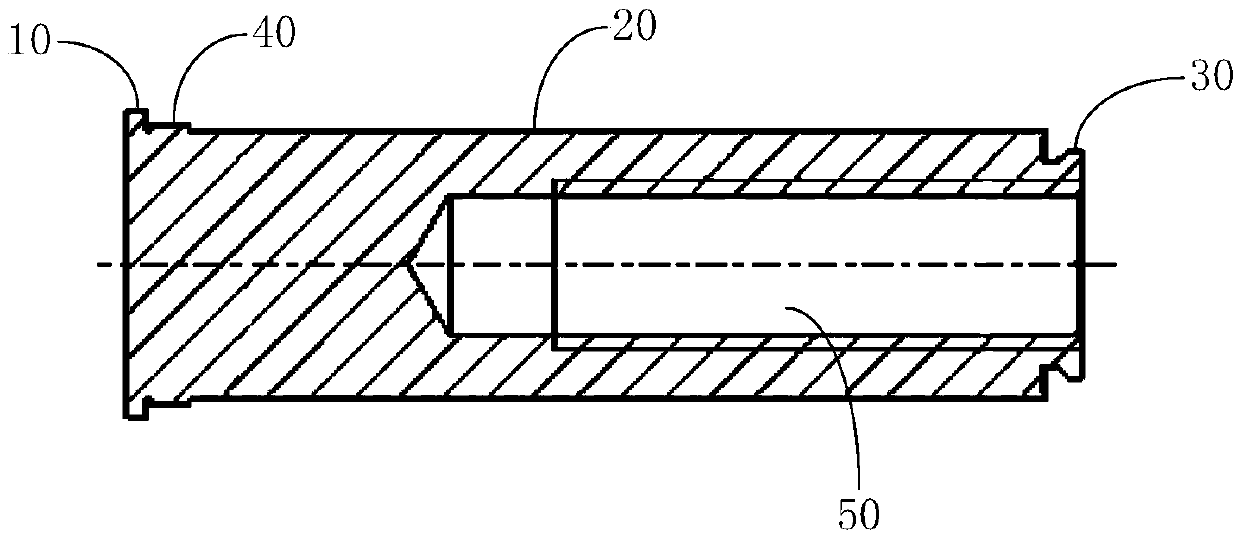

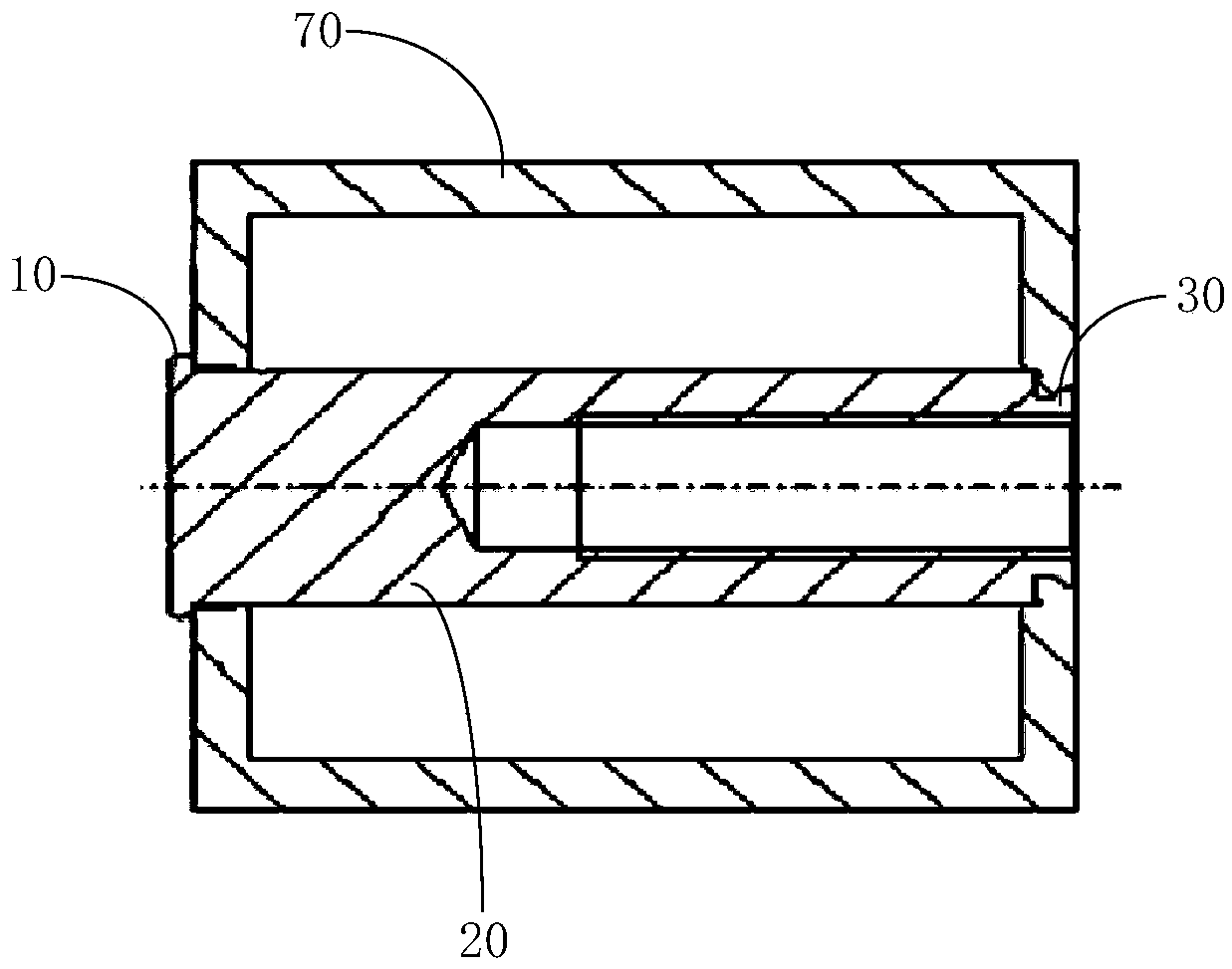

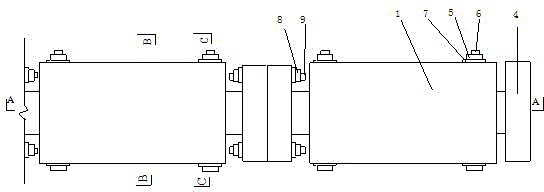

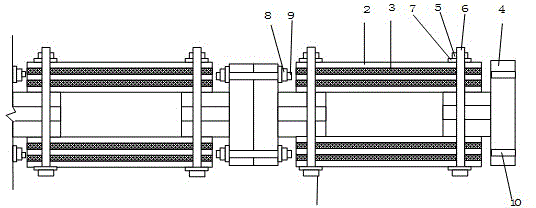

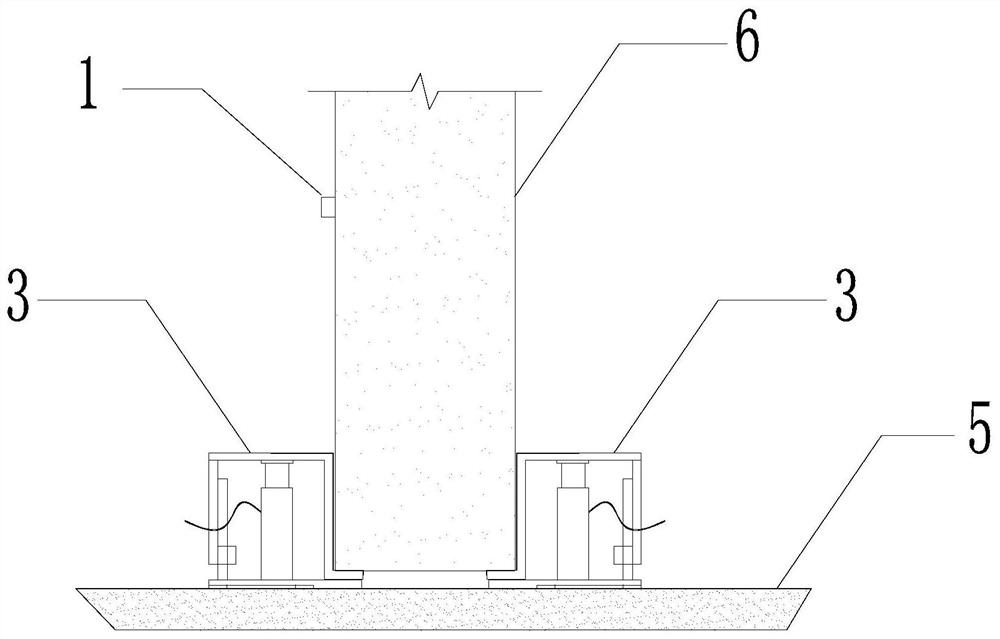

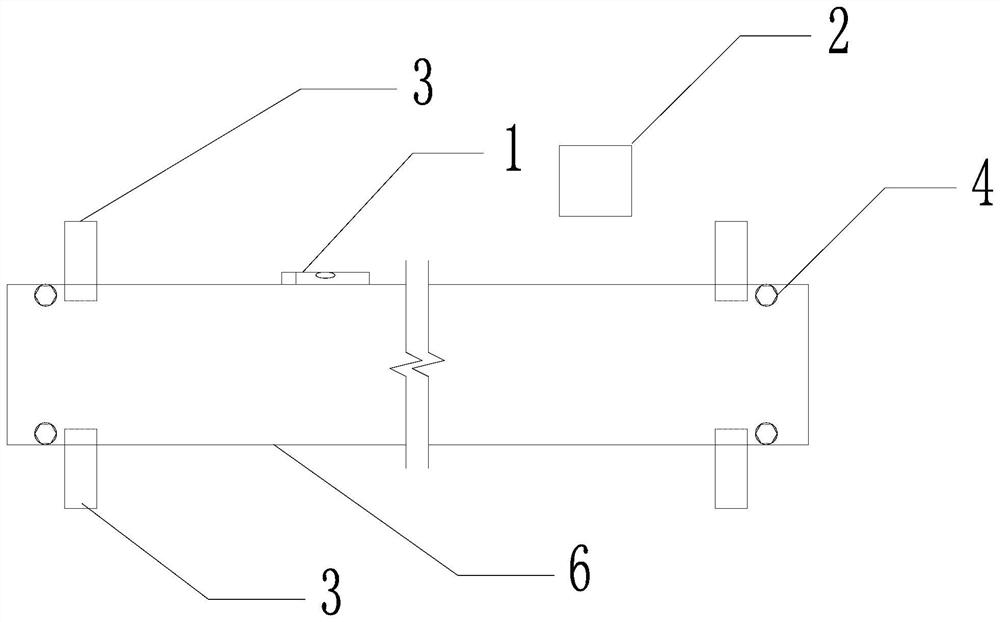

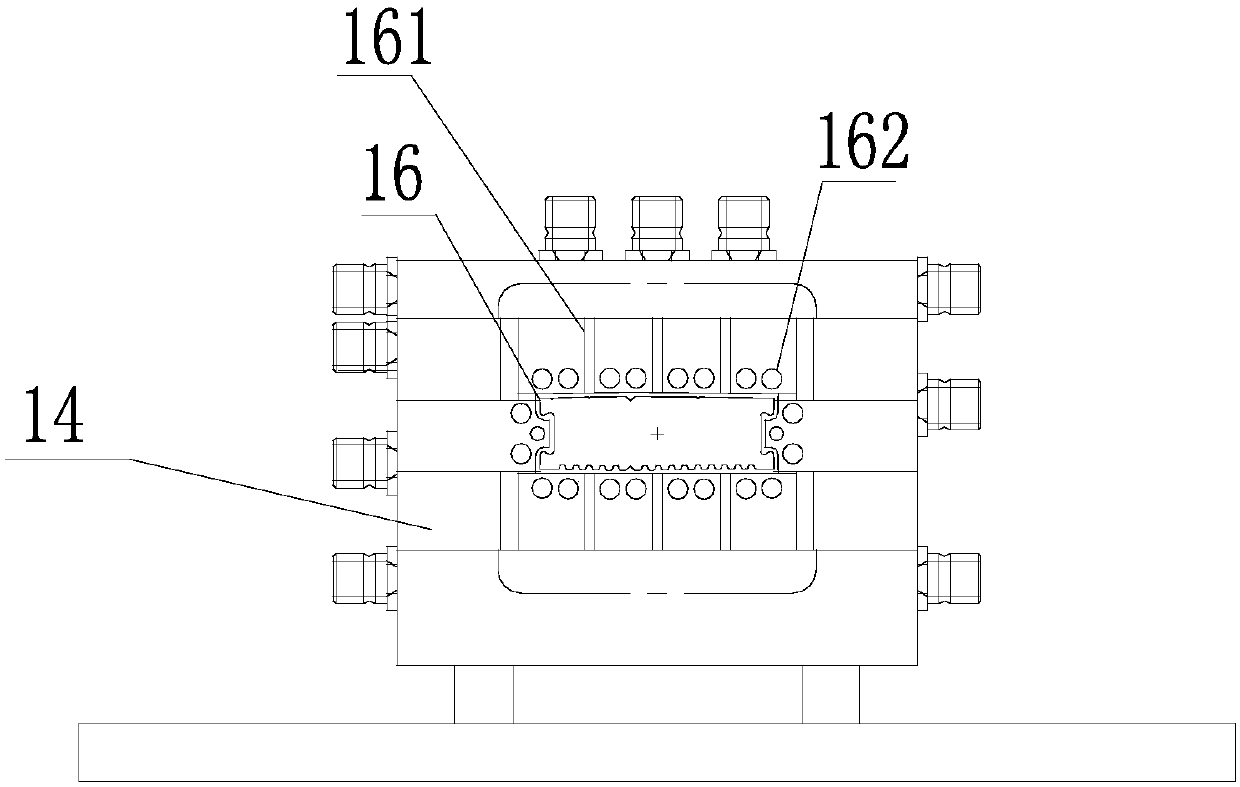

Cylinder assembled steel lead damper

InactiveCN104405056AImprove coordinationImprove mechanical performanceShock proofingControl theoryEnergy consumption

The invention discloses a cylinder assembled steel lead damper. The damper comprises at least two groups of cylinder assembled lead steel damper units, and each group of cylinder assembled lead steel damper units are connected in series. Each group of cylinder assembled lead steel damper units comprises a cylinder energy consumption body and connecting pieces, wherein each cylinder energy consumption body comprises a lead cylinder and a soft steel cylinder; the soft steel cylinder is arranged on the outer side of the lead cylinder in a sleeving and embedding manner; the connecting pieces are arranged at the two ends of each cylinder energy consumption body. The cylinder assembled steel lead damper has the advantages and the beneficial effects that the rigidity is high; the soft steel cylinder and the lead cylinder have better coordination; the material utilization rate is high; the energy consumption effect is good; the cylinder assembled steel lead damper is mounted by connecting precast components by bolts and nuts; the damping can be adjusted according to requirements; the cylinder assembled steel lead damper is convenient to assemble, easy to construct and controllable in installation quality; each cylinder energy consumption component is high in mechanical performance, and can resist to earthquake actions in all directions, and consume the energy of the earthquake actions in different directions; the cylinder assembled steel lead damper can be used for an earthquake resistant design of a new construction project, and can also be used for the reinforcement and the repair of an existing project.

Owner:SHENYANG JIANZHU UNIVERSITY

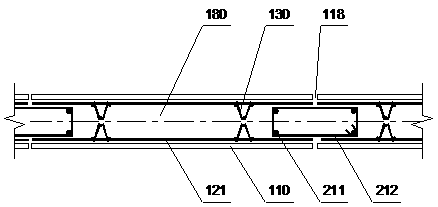

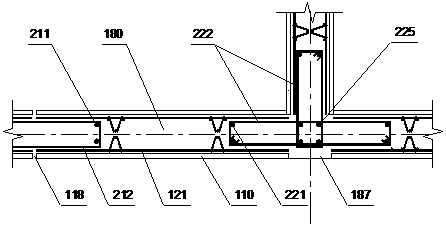

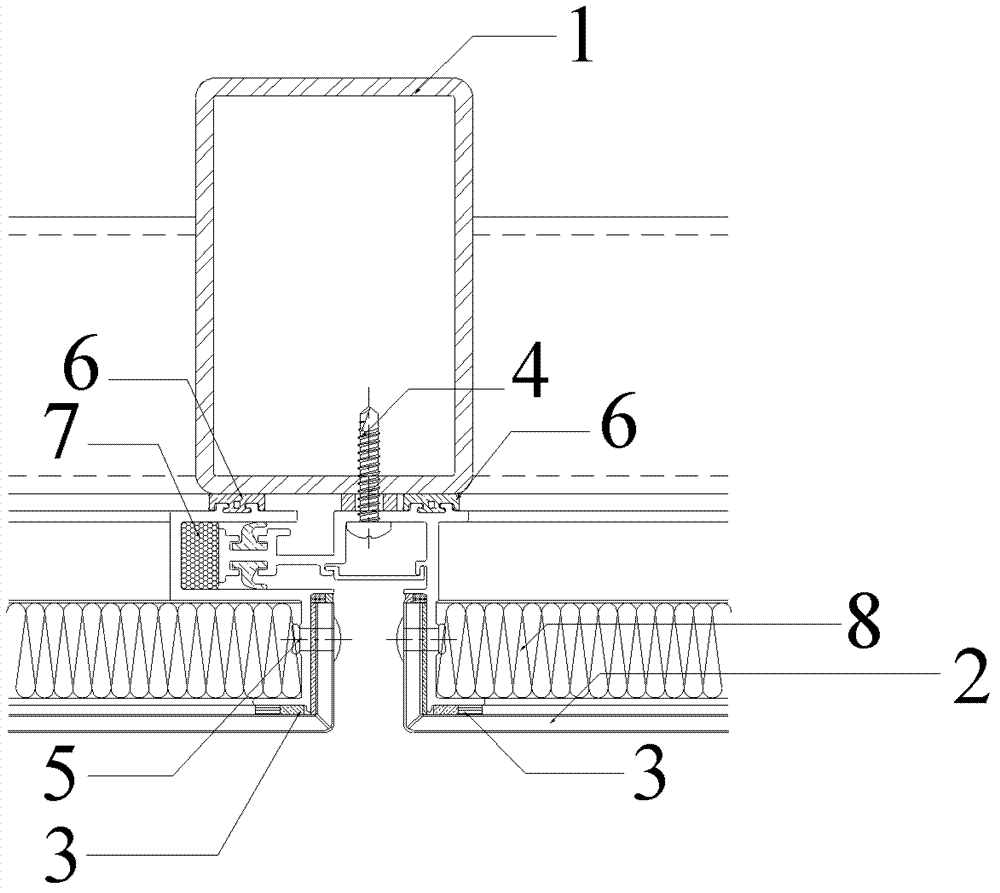

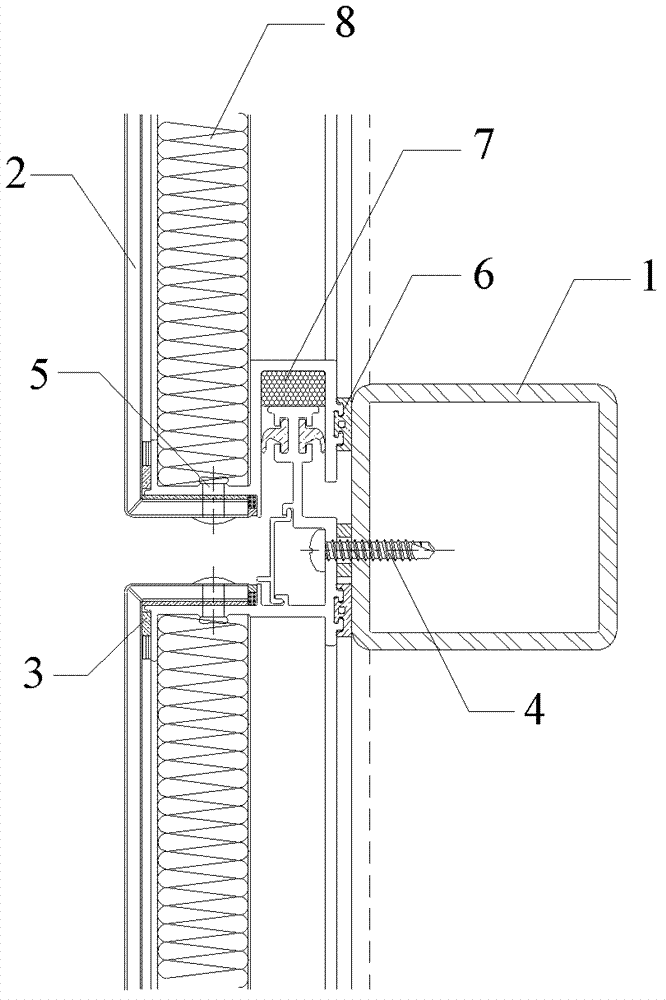

Half tenon riveting type aluminum plate connection device

InactiveCN102953463AInstallation quality is easy to controlSave installation timeWallsSealantAluminium alloy

The invention relates to a half tenon riveting type aluminum plate connection device which comprises a galvanized square tube, an aluminum alloy cover plate and two composite aluminum plates. The aluminum alloy cover plate is arranged below the galvanized square tube and connected with the galvanized square tube through stainless steel tapping screws, and the two composite aluminum plates in transverse L-shaped structure are symmetrically arranged below the aluminum alloy cover plate and connected with the aluminum alloy cover plate. Compared with the prior art, only two sides of the half tenon riveting type aluminum plate connection device are connected with transoms and mullions while the other sides of the device are inserted into grooves of adjacent plates and sealed by rubber strips, sealant is not needed, mounting quality is easy to control, mounting time can be saved, and fine appearance effects can be achieved.

Owner:SHANGHAI MEITE CURTAIN WALL

Steel slag light partition wall, as well as preparation method and assembly process of light partition wall

The invention discloses a steel slag light partition wall, as well as a preparation method and assembly process of the light partition wall. The light partition wall is prepared from the following raw materials by weight percent: 15-20 percent of slag, 7-8 percent of mineral powder, 8-10 percent of porcelain particles, 6-8 percent of pulverized fuel ash, 1-3 percent of additives, 25-30 percent of cement and the balance of water. The preparation method comprises the following steps: respectively grinding and screening the slag, mineral powder, porcelain particles, pulverized fuel ash and cement for later use; then, uniformly mixing and stirring the ground and screened raw materials with other raw materials to obtain a mixture; and finally, extruding and molding the obtained mixture through an extruder to obtain the target product. The light partition wall prepared by using steel slag as the main raw material has the advantages of wide raw material, simple manufacture, high construction speed, convenience in controlling of assembly quality, free plastering, light weight, good sound insulating effect and the like.

Owner:CCFED THE FIGTH CONSTR & ENG

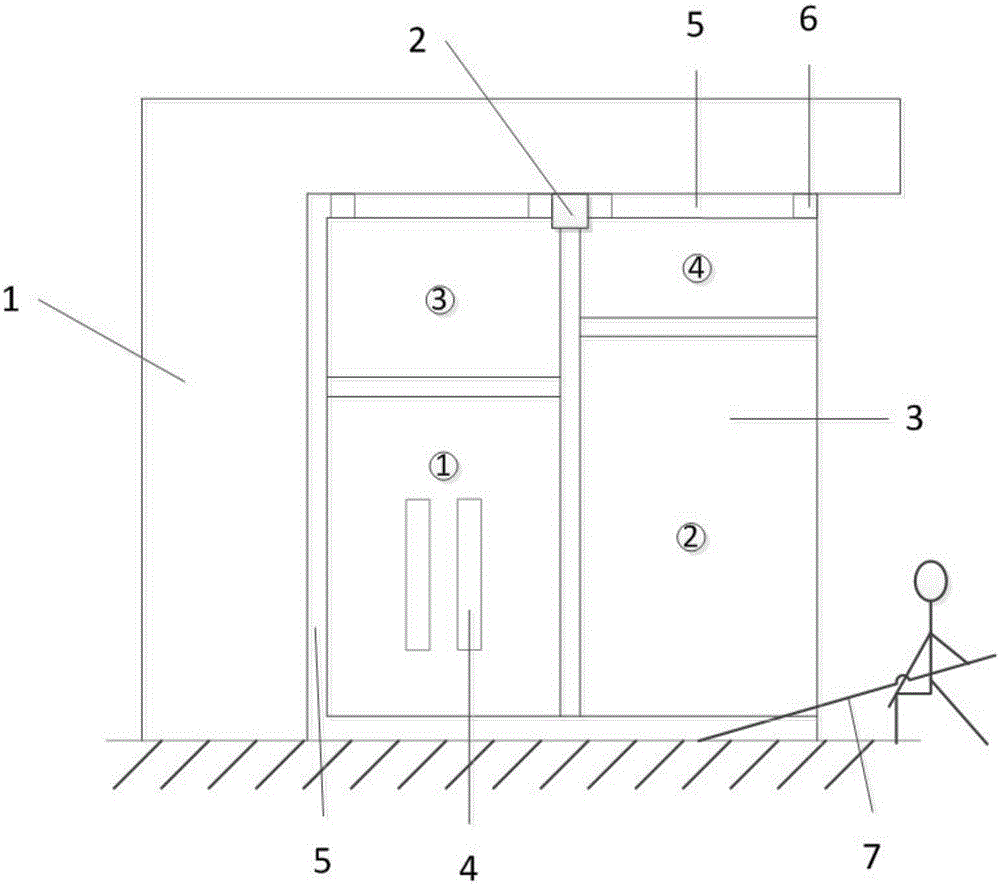

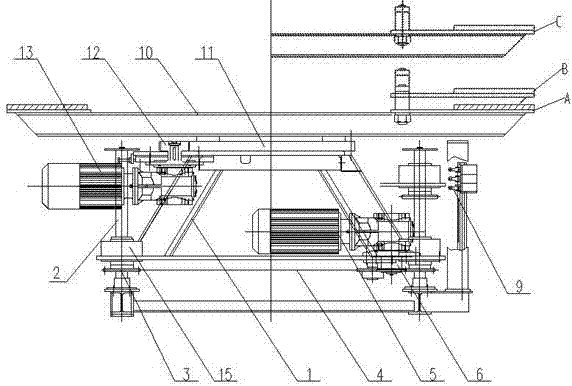

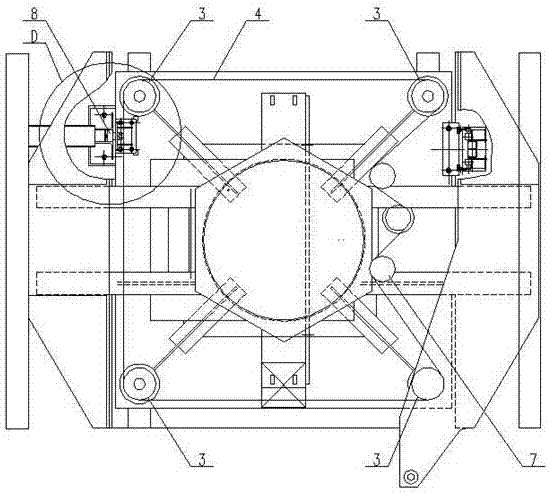

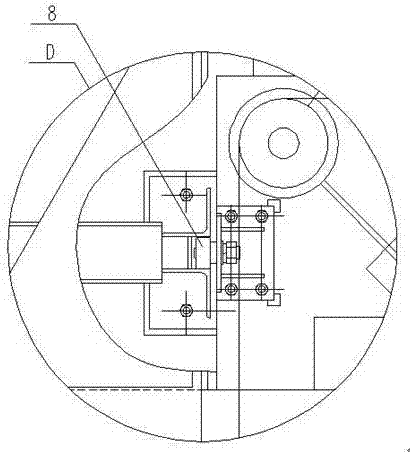

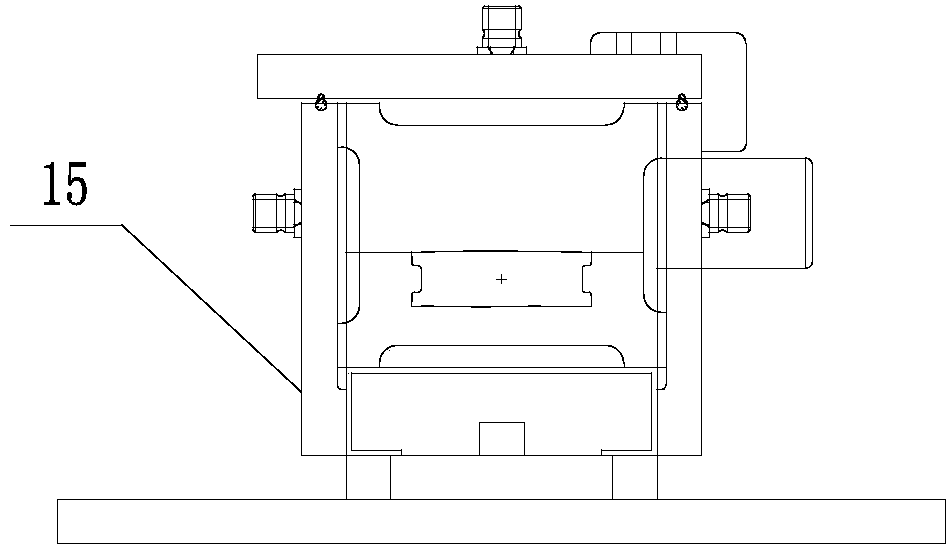

Special lifting and revolving platform for towered garage

The invention discloses a special lifting and revolving platform for a towered garage. The special lifting and revolving platform comprises a lower support platform, a lifting mechanism, a travel switch group, an upper revolving platform and a revolving mechanism. The upper revolving platform is arranged above the lower support platform. The lifting mechanism is used for driving the lower support platform to move up and down slightly and driving the lower support platform and the upper revolving platform to move up and down slightly together. The revolving mechanism is used for driving the upper revolving platform to rotate on the lower support platform. The travel switch group is arranged on a lift car. The special lifting and revolving platform for the towered garage is an integrated lifting and revolving lift car platform which is compact in structure and capable of moving up and down slightly during revolving, so that car access time is saved.

Owner:JIANGSU PARKTEC PARKING EQUIP

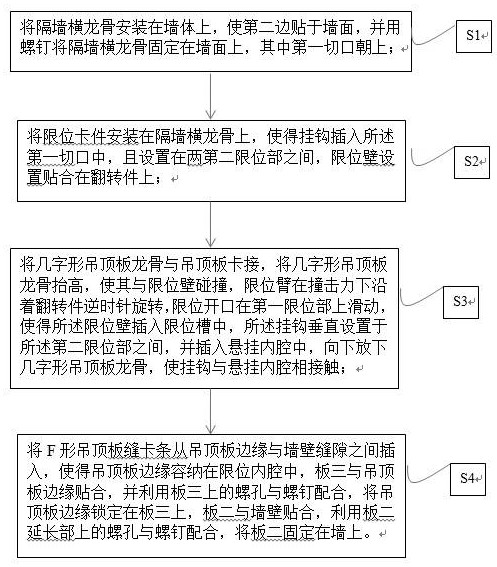

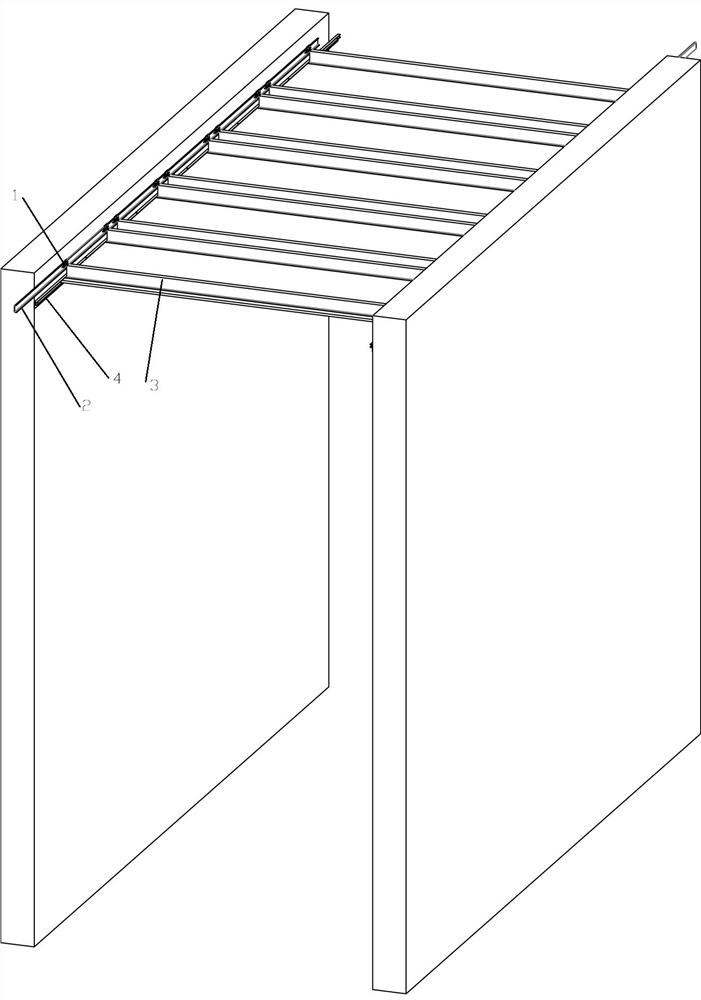

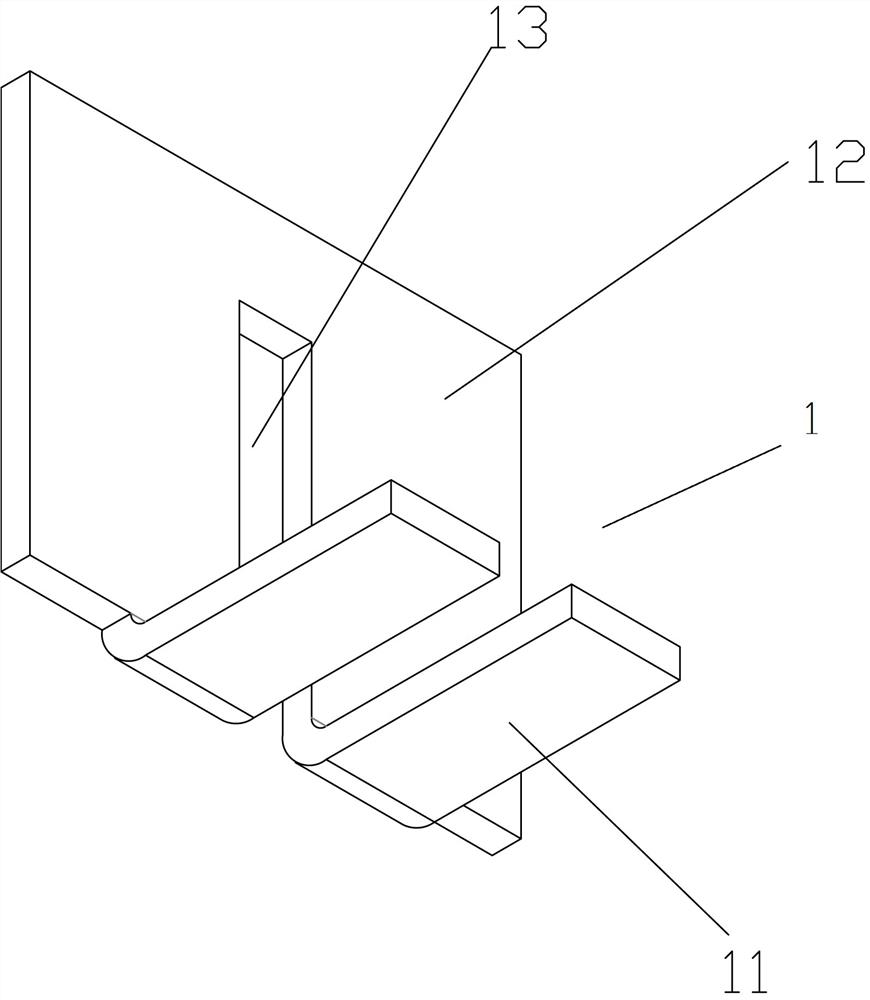

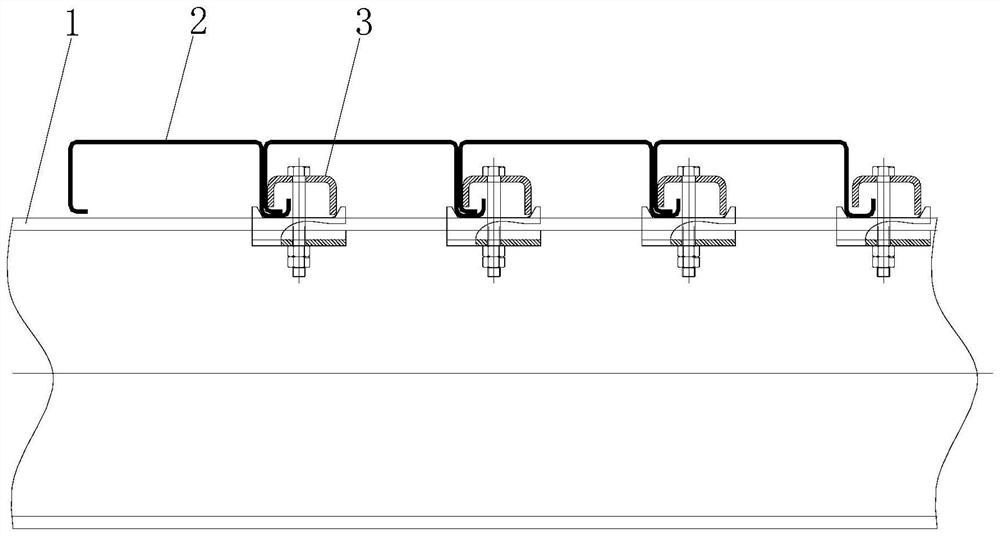

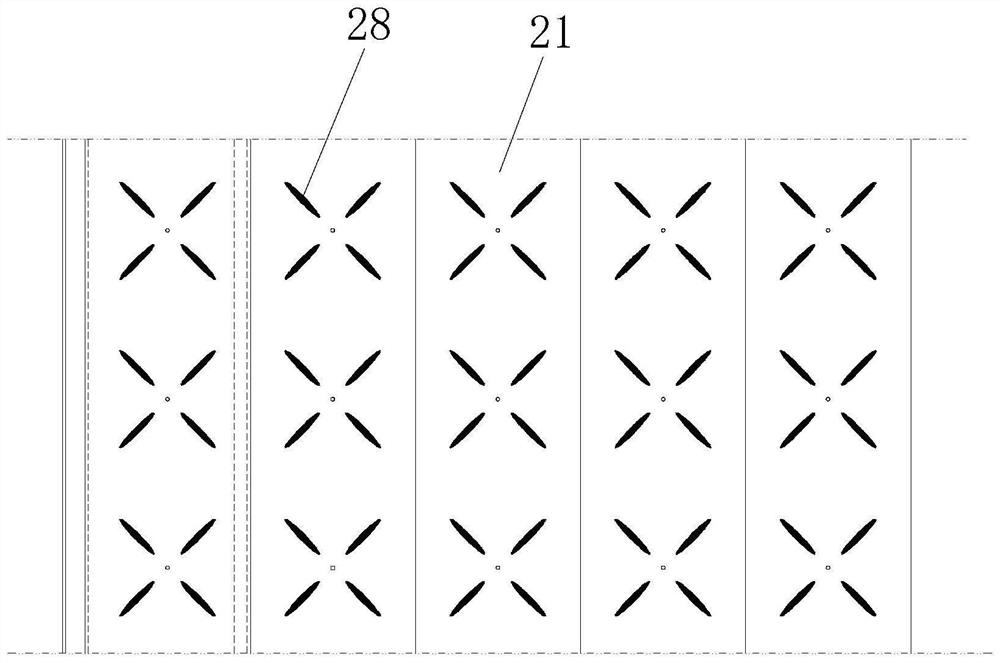

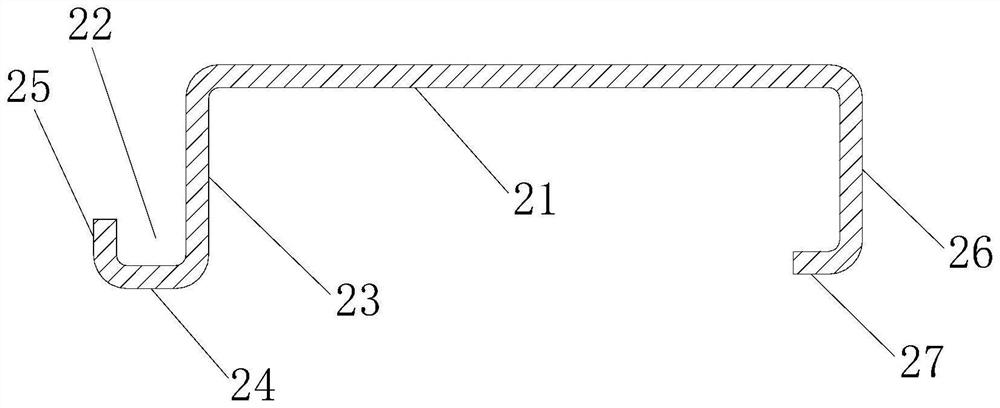

Small-space suspender-free clamping suspended ceiling and mounting method

The invention provides a small-space suspender-free clamping suspended ceiling. The small-space suspender-free clamping suspended ceiling comprises a partition wall transverse keel, a limiting clamping piece, an n-shaped suspended ceiling plate keel and an F-shaped suspended ceiling plate seam clamping strip, wherein the partition wall transverse keel is installed on a suspended ceiling wall, thelimiting clamping piece is used as a connecting device for connecting the partition wall transverse keel with the n-shaped suspended ceiling plate keel, and the limiting clamping piece is clamped on the partition wall transverse keel, so that the inconvenience in operation in a screw fixing process is avoided; and the F-shaped suspended ceiling plate seam clamping strip is used for fixing a suspended ceiling plate, so that the stability of the suspended ceiling plate is increased, the suspended ceiling plate can adapt to the existence of wind pressure, the suspended ceiling plate cannot shakeor swing, and on the other hand, a gap between the suspended ceiling plate and the wall is sealed by the F-shaped suspended ceiling plate seam clamping strip. The invention further provides a mountingmethod of the small-space suspender-free clamping suspended ceiling. The suspended ceiling structure does not need to be suspended by a suspender, an original floor slab is not damaged, the suspendedceiling space is saved, additionally, the structure is compact, the occupied space is small, the installation steps are few, and the operation is convenient.

Owner:ZHEJIANG YASHA DECORATION

Building of steel frame and concrete shear wall structure and construction method for building of steel frame and concrete shear wall structure

PendingCN111075064AReduce workloadHigh degree of automationWallsBuilding reinforcementsArchitectural engineeringMesh reinforcement

The invention relates to a building of a steel frame and concrete shear wall structure and a construction method for the building of the steel frame and concrete shear wall structure. The building comprises a steel frame structure and shear wall bodies arranged in the steel frame structure. Each shear wall body is mainly composed of steel bar truss fixing formworks located on the two sides of thewall body and a concrete layer poured between the steel bar truss fixing formworks on the two sides. Each steel bar truss fixing formwork comprises a face plate, a steel mesh and steel bar trusses, wherein the steel mesh and the steel bar trusses are located on the inner side of the face plate and are solidified in the corresponding concrete layer. Corresponding steel bar connecting stands are arranged in various wall body joints respectively. In the construction method, construction of the shear wall bodies comprises the steps of formwork installing, formwork fixing, concrete pouring, wall body maintaining and the like. The building of the steel frame and concrete shear wall structure and the construction method for the building of the steel frame and concrete shear wall structure are beneficial to reduction of the work amount and labor intensity of shear wall construction, the degree of influences of human factors on building quality can be reduced, construction cost can be reduced,arrangement of pipelines on the building can be facilitated, and the adverse effect brought by arrangement of the pipelines on the wall bodies can be relieved or avoided.

Owner:ZHONGQINGDA TECH HLDG CO LTD

Safety protection window bar and installation method thereof

ActiveCN111779207ANovel structureEasy to assemble and disassembleBalustersBalustradesWindow sillEngineering

Owner:梅名扬

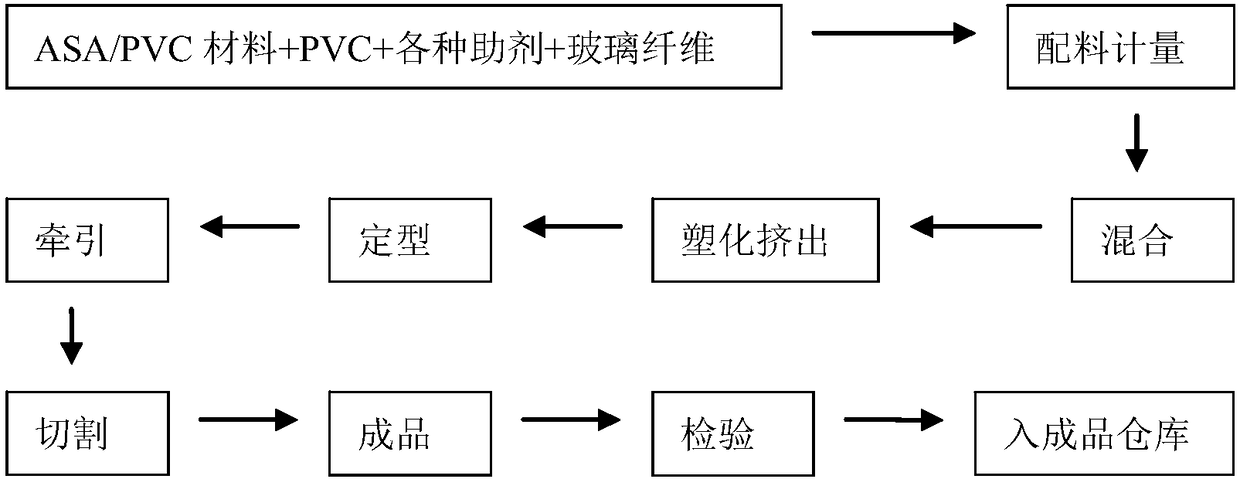

A processing technology of high-strength and low-creep pvc energy-saving frame

The invention relates to a processing technology of a high-strength low-creep PVC energy-saving auxiliary frame. The processing technology comprises the following steps that 1, an auxiliary frame material is prepared by mixing, by weight, 100 parts of an ASA-PVC material, 15-50 parts of PVC, 2-4 parts of a processing auxiliary, 2-4 parts of a stabilizer, 1-4 parts of titanium dioxide, 10-40 parts of calcium carbonate, 0.1-1 part of an inner lubricant, 0.1-1 part of an outer lubricant and 0.5-20 parts of fiber glass filaments; 2, a mixture obtained in the step 2 is added into a plastic extruding machine to be plastified and extruded; 3, an extruding product obtained in the step 2 is contained in a mold to be shaped; 4, drying is conducted, wherein a product obtained in the step 3 is dried; 5, cutting is conducted. According to the processing technology, the problems that a general plastic auxiliary frame has obvious thermal expansion and cold contraction phenomena and is prone to deform are solved, the size and position of a door window can be determined, and the installation quality of the door window is more easily controlled.

Owner:HUAZHIJIE PLASTIC BUILDING MATERIAL CO LTD

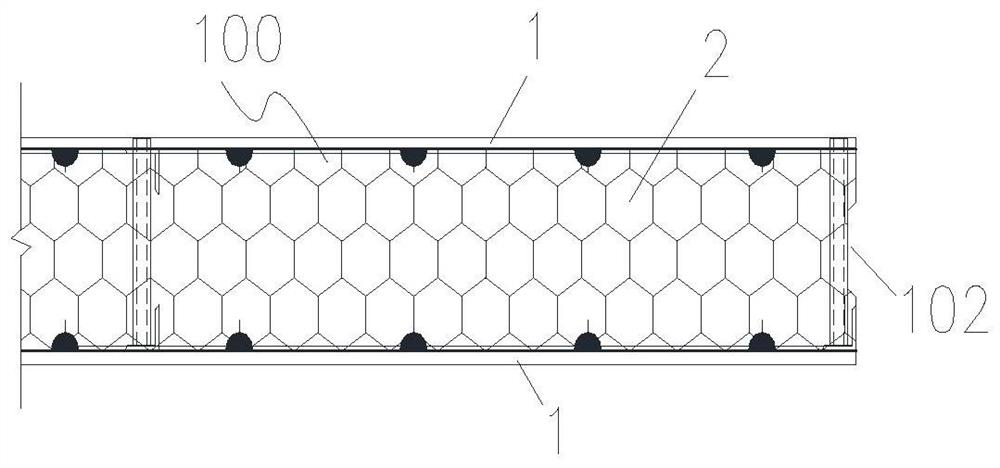

Fabricated cement fiberboard composite wallboard, manufacturing process and outer wall

ActiveCN112227594AImprove corrosion resistanceGood weather resistanceConstruction materialBuilding reinforcementsFoam concretePortland cement

The invention provides a fabricated cement fiberboard composite wallboard. The composite wallboard is composed of cement fiberboards and foam concrete, the cement fiberboards serve as shells of the composite wallboard to be attached to the front face and the back face of the foam concrete, and a light steel keel stress structure is additionally arranged in the foam concrete; the foam concrete is prepared from the following components in parts by weight: 80-90 parts of quick-hardening Portland cement, 4-5 parts of lime, 0.4-0.5 part of ceramsite, 3-7 parts of a slurry stabilizer, 48-55 parts ofwater and 0.1-0.5 part of foam; and the left side and the upper side of the composite wallboard are provided with convex rabbets, and the right side and the lower side of the composite wallboard areprovided with concave rabbets. The super-long service life is ensured, the adaptability to various climates is better, and the fabricated cement fiberboard composite wallboard can be widely applied tobuilding places with high requirements on heat insulation performance.

Owner:FUJIAN YONGFU POWER ENG

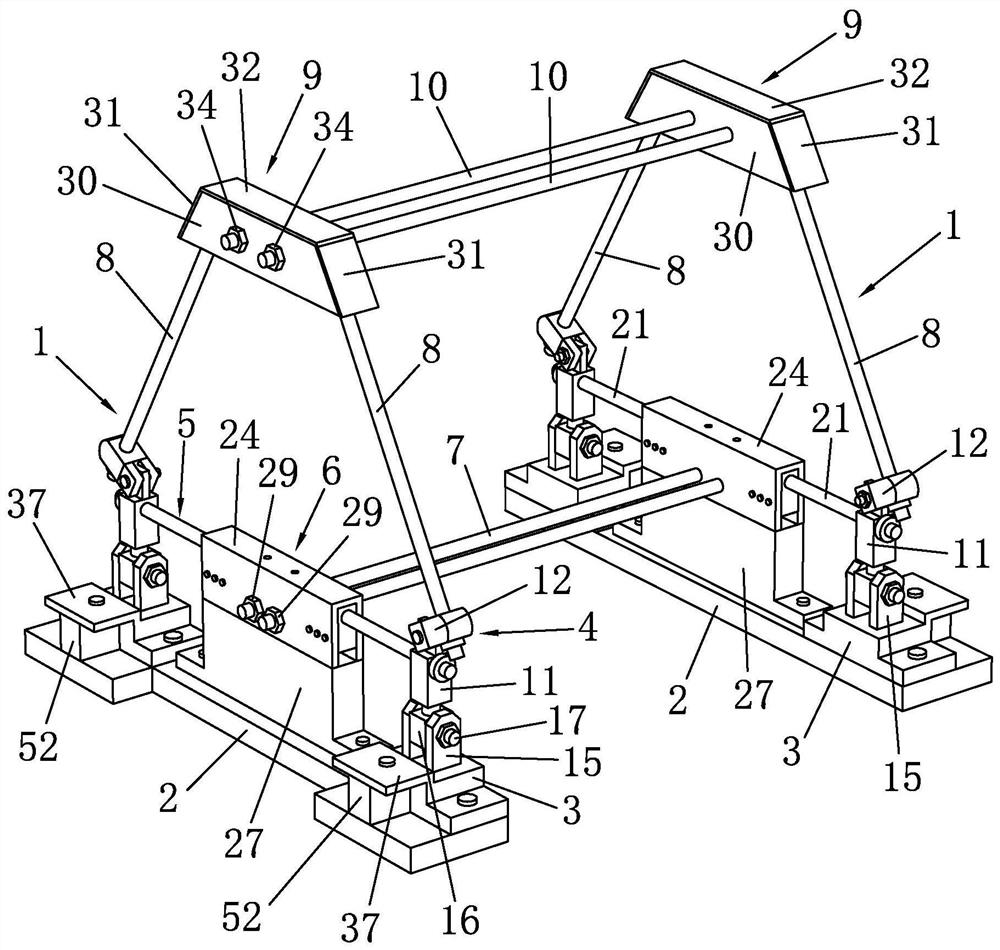

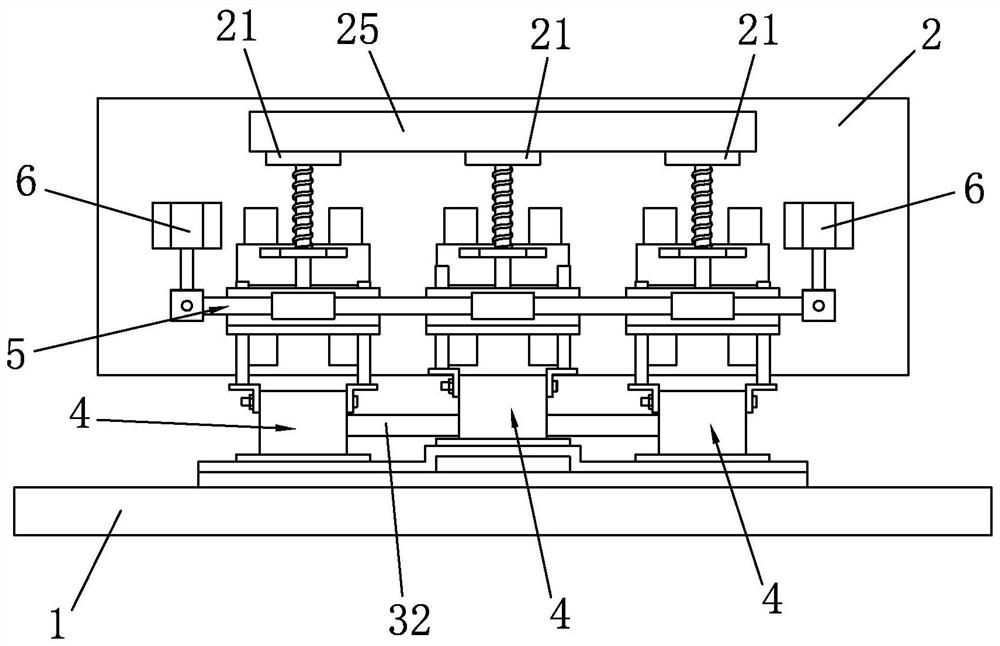

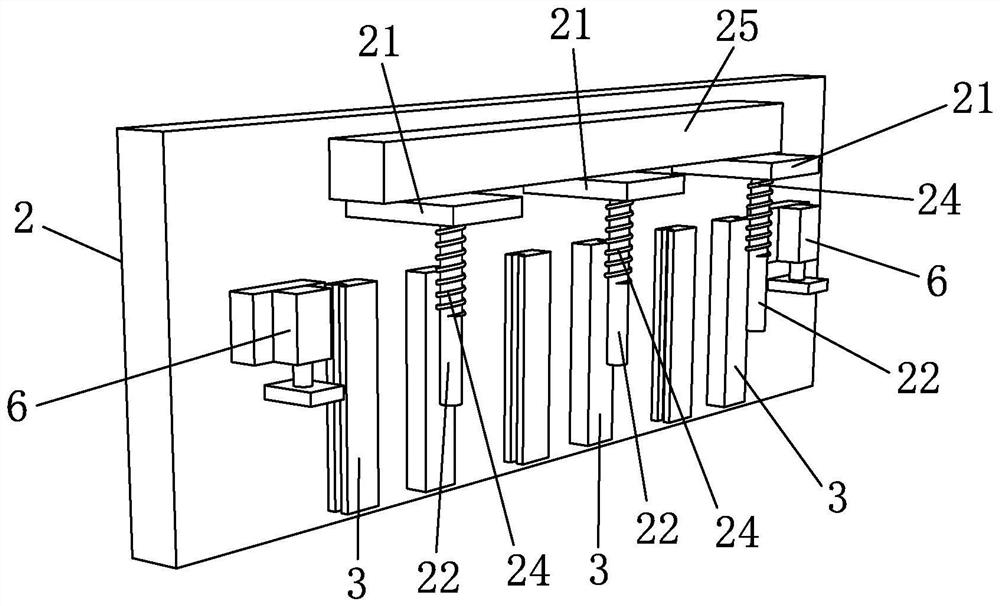

Mounting and adjusting equipment for vertical prefabricated part

PendingCN113152911AEasy to operateAccurate installation postureBuilding material handlingEngineeringElectrical and Electronics engineering

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

Turnbuckle nut, fastener and installation method thereof

Owner:PEM CHINA

Garage mounting structure

PendingCN114059824ASimple structureIncrease production capacityBuilding constructionsParkingsEngineeringStructural engineering

Owner:中鸿建辉(北京)控股有限公司

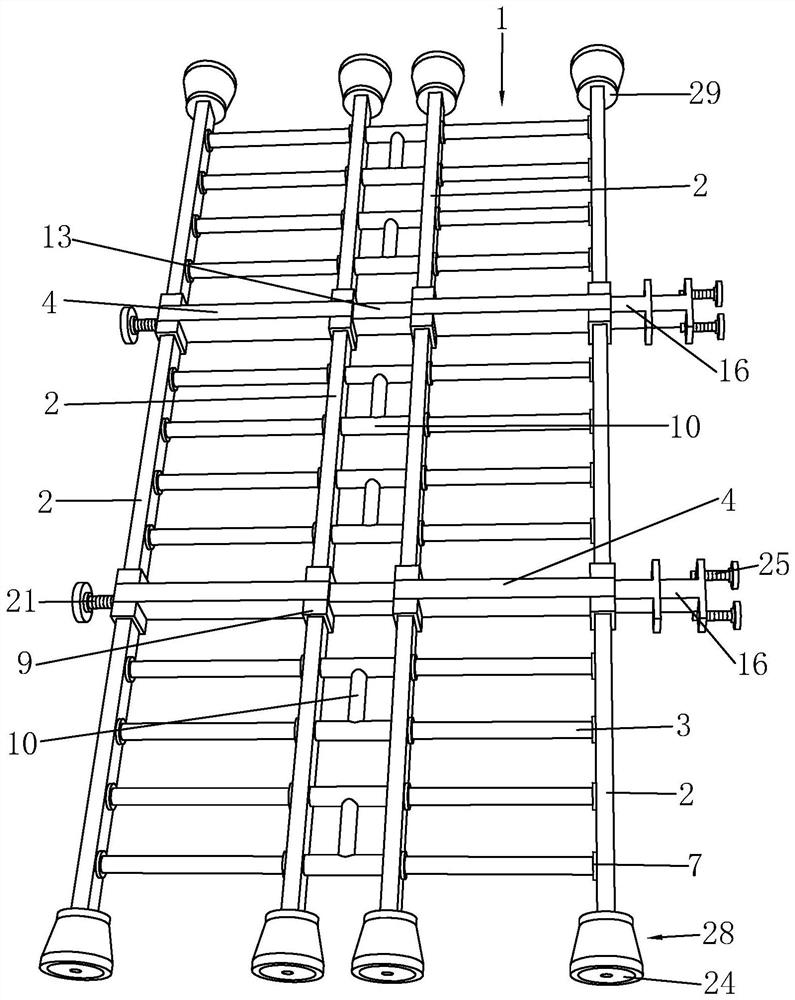

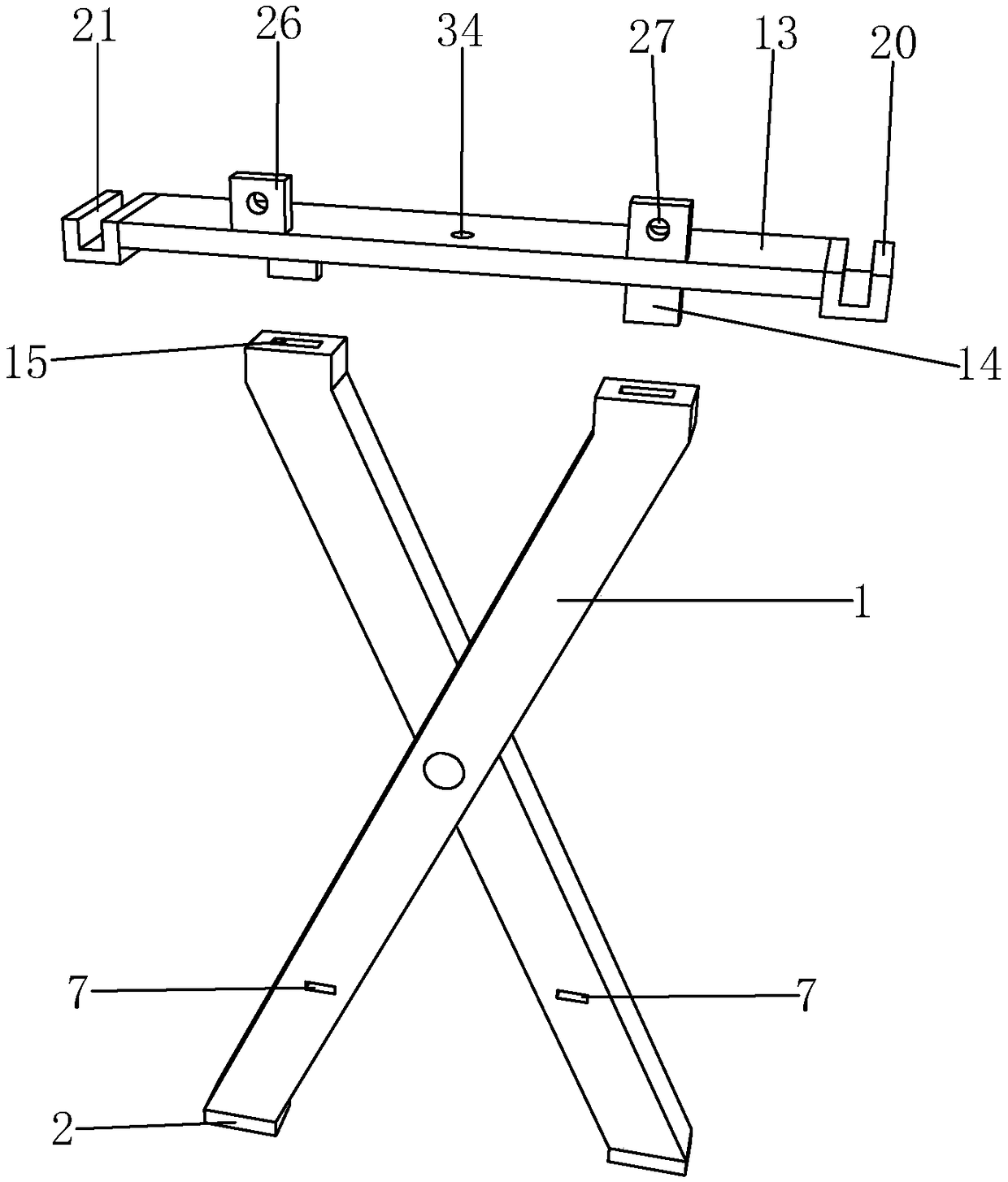

3D printer stand and its installation method

ActiveCN112519214BImprove stabilityMeet installation needsAdditive manufacturing apparatusComputer printingStructural engineering

The invention discloses a 3D printer bracket and an installation method thereof, comprising a mounting seat and an angle adjustment connecting bracket, a first connecting rod is arranged between the angle adjusting connecting brackets, the first connecting rod is provided with a first rod assembly device, and the first rod There is a second connecting rod between the assembling devices, the angle adjustment connecting bracket has a third connecting rod, a second connecting rod is installed between the third connecting rods, and a fourth connecting rod is installed between the second connecting rods. Connecting rod. The method includes: a. assembling the mounting seat; b. installing the angle-adjusting connecting bracket; c. adjusting the angle-adjusting connecting bracket to a horizontal state; d. installing the first connecting rod and the first rod assembly device; e. installing the third connection rod; f, install the second rod assembly device; g, adjust the third connecting rod and the first connecting rod; h, install the second connecting rod and the fourth connecting rod; i, install the base. It can increase the stability of the entire 3D printer bracket, and can meet the installation requirements of the printing platform and the nozzle mechanism.

Owner:台州新森增材制造有限公司

Energy-saving auxiliary frame mould

InactiveCN107932869AHigh static bending strengthSmall dimensional change rateDomestic articlesWater channelButt joint

The invention discloses an energy-saving auxiliary frame mould comprising a mould head used for extrusion molding, and a stock mould and a water cooling box which are in butt joint with the mould head. The mould head is provided with a machine neck of which the tail end is provided with a shunt support plate, a mandril support plate, a compressing plate, a performing plate and a forming plate by lock screws in sequence, and the middle part of the machine neck is provided with a shunt cone, an internal flow passage and a main core; and the front end side of the main core is provided with another smaller core which extends into the stock mould. The stock mould is internally provided with a setting cavity of which the shape is the same as the shape of a workpiece, and the inner wall of the setting cavity is provided with a vacuum gas groove which communicates with the setting cavity; and the side of the vacuum gas groove is provided with a plurality of cooling water channels. An output port, relative to the stock mould, of the water cooling box is provided with an input port of which the shape is the same as the shape of the workpiece. Energy-saving auxiliary frame profiles produced with the mould disclosed by the invention have the advantages of high static bending intensity, low rate of change in size after heating, energy saving, environmental protection, etc., and the problemsof obvious thermal expansion and contraction and easy deformation of a previous mould are solved.

Owner:HUANGSHI SANMU PLASTIC MOLD

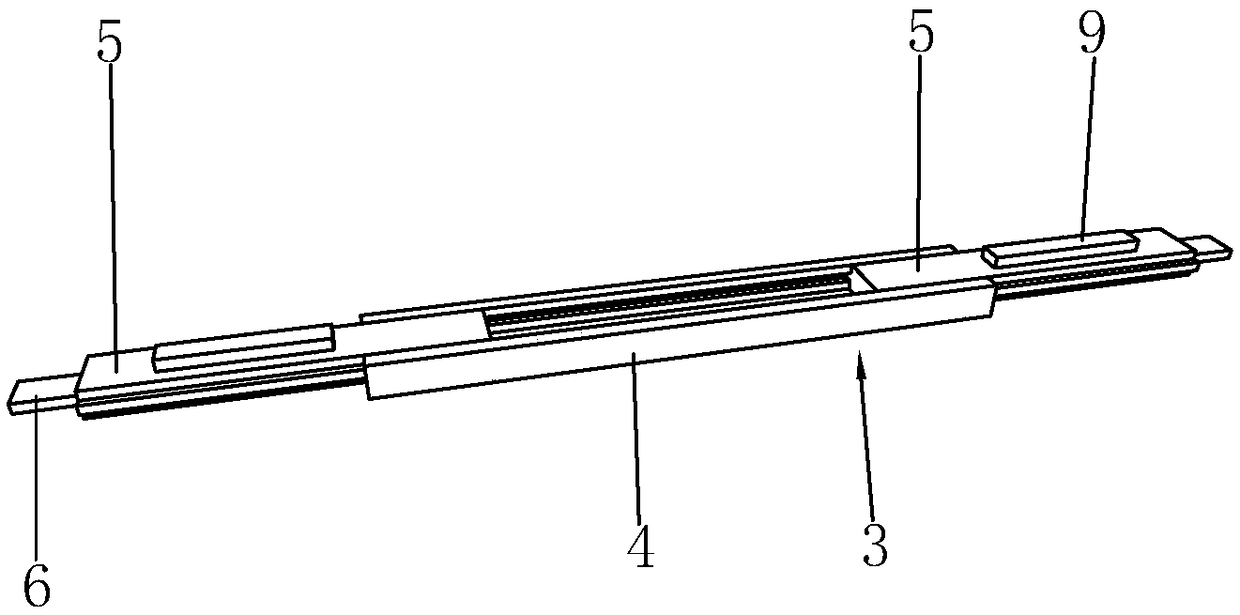

Clothes drying rack for life and installation method thereof

ActiveCN109162070AAvoid easy separationNot easy to fall offOther drying apparatusTextiles and paperWhole bodyEngineering

The invention discloses a clothes drying rack for life and an installation method thereof. The clothes drying rack comprises cross rods, two telescopic shelves are snapped between the cross rods, thetelescopic shelves are provided with half shells, the cross rods are provided with limiting plates, the bottom surfaces of the limiting plates are provided with positioning clamping blocks, the tops of the cross rods are provided with positioning clamping grooves which are corresponding to the positioning clamping blocks, and a clothes drying rod and a telescopic hanging rod are arranged between the limiting plates. The installation method comprises the steps of (a) base assembly, (b) adjustment, (c) lower part installation, (d) upper part installation, and (e) residual part installation. Theclothes drying rack has the advantages of simple assembly, low operation difficulty, large drying space, separate drying of upper and lower layers, high drying efficiency, uniform storage after disassembly and convenience in carrying, the installation method is easy to operate, labor-saving and convenient, reasonable and orderly, from a whole body to a local part, from the bottom to top, the operation space is large, the installation process can be flexibly adjusted, and the installation quality is easy to control.

Owner:邵奕舟

Method for prefabricating equipment foundations and effectively fixing equipment foundations

InactiveCN112982474AGuaranteed accuracyGuaranteed construction periodFoundation engineeringNumerical controlConstruction engineering

The invention discloses a method for prefabricating equipment foundations and effectively fixing the equipment foundations. The method comprises the following steps that S1, a BIM technology is utilized, factors such as construction and installation, energy conservation and environmental protection and operation and maintenance are fully considered to carry out deepening design on pipelines and the equipment foundations in a machine room, and an equipment foundation size positioning drawing is exported; S2, the equipment foundations are prefabricated, a prefabrication base is established or a prefabrication factory is entrusted, and streamlined numerical control machining is carried out in a factory workshop according to the equipment foundation machining drawing exported by a high-precision BIM model; S3, the prefabricated equipment foundations are transported, and the number of ground tanks and traction winches are determined according to the size and the weight of each prefabricated equipment foundation for transportation in place; and S4, the equipment foundations are fixed, laser paying-off positioning is utilized, the accuracy of each equipment foundation is ensured, and the equipment foundations are transported to the positioning positions to slowly fall to the ground. According to the method, the construction period is guaranteed, the positions of the equipment foundations can be moved at any time, and the production and installation quality of the equipment foundations is controllable.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

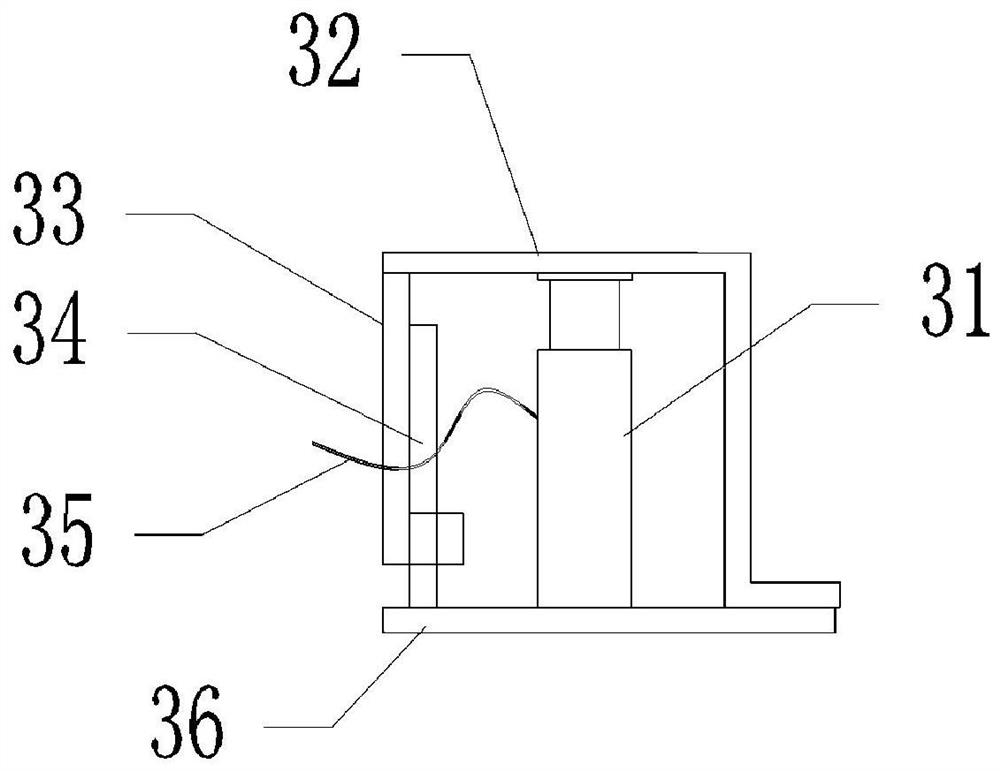

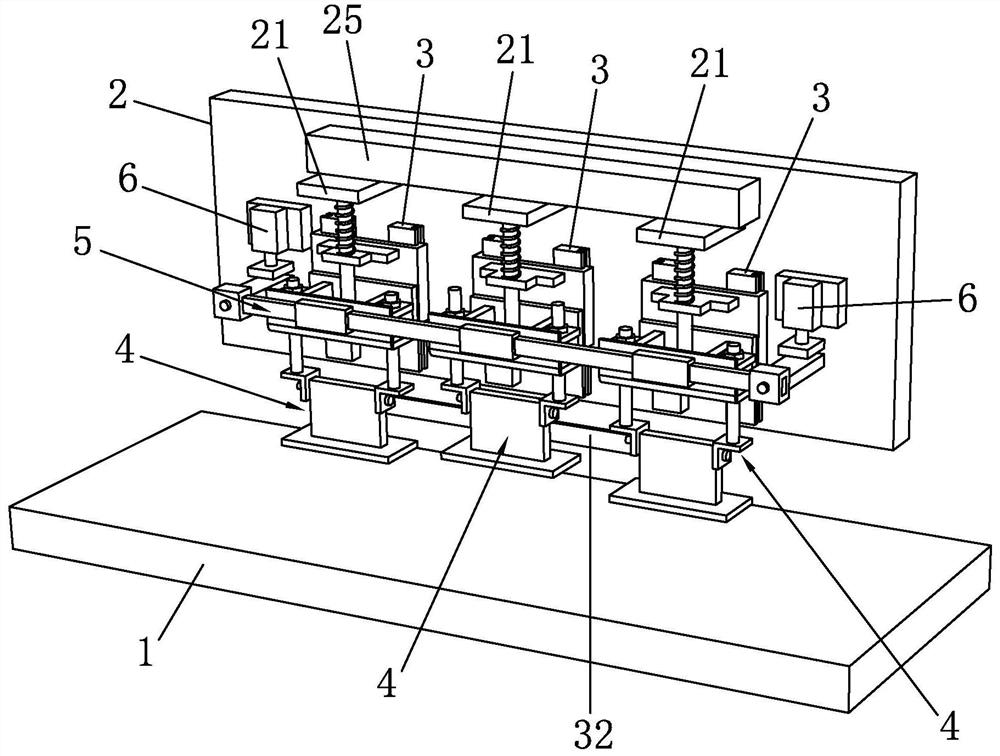

A reinforcement plate installation device for the convex surface of the panel of the integrated stove cabinet

ActiveCN109397195BImprove connection strengthAvoid crackingMetal-working hand toolsHydraulic cylinderEngineering

The invention discloses a reinforcing plate installation device for the convex surface of the integrated kitchen cabinet body panel, which includes a conveying table and an installation body. The installation body is provided with three sets of sliding rails, and a single set of sliding rails is slidingly connected with a pressing device in the middle The distance between the bottom surface of the pressing device and the conveying platform is greater than the distance between the bottom surface of the pressing device on both sides and the conveying platform, and the distance between the bottom surface of the pressing device on the left and the conveying platform is equal to that on the right The distance between the bottom surface of the lower pressing device on the side and the conveying table, a driving bracket is provided between the three pressing devices, and a hydraulic cylinder is provided on the installation body, and the hydraulic cylinder drives the driving bracket. The present invention can continuously apply force at three points evenly to the reinforcing plate placed on the convex surface, quickly bond and fix the reinforcing plate on the convex surface on the back of the cabinet body panel of the integrated stove, and increase the distance between the panel of the cabinet body and the handle of the cabinet body. The connection strength has the effects of automation, safety, easy control of installation quality and convenience for mass production.

Owner:杨位芳

Disassembly-free formwork concrete shear wall structure building and construction method thereof

PendingCN111075063AReduce workloadHigh degree of automationWallsBuilding reinforcementsArchitectural engineeringMesh reinforcement

The invention relates to a disassembly-free formwork concrete shear wall structure building and a construction method thereof. A shear wall body in the building is mainly composed of steel bar truss fixing formworks positioned on the two sides of the wall body and a concrete layer poured between the steel bar truss fixing formworks on the two sides, wherein the steel bar truss fixing formworks comprise panels, and steel bar meshes and steel bar trusses which are positioned on the inner sides of the panels; the steel bar meshes and the steel bar trusses are consolidated in the concrete layer; and corresponding steel bar connecting frames are respectively arranged in various wall body joints. The construction of the shear wall body in the construction method comprises the steps of formwork installation, formwork fixing, concrete pouring, wall body maintenance and the like. According to the disassembly-free formwork concrete shear wall structure building and the construction method thereof, the workload and working strength of building construction are favorably reduced, the influence degree of human factors on the building quality is reduced, the construction cost is reduced, the pipeline arrangement on the building is convenient, and the negative influence of the pipeline arrangement on the wall body is reduced or avoided.

Owner:ZHONGQINGDA TECH HLDG CO LTD

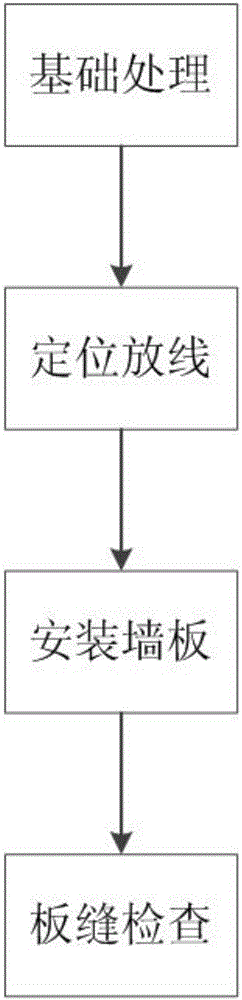

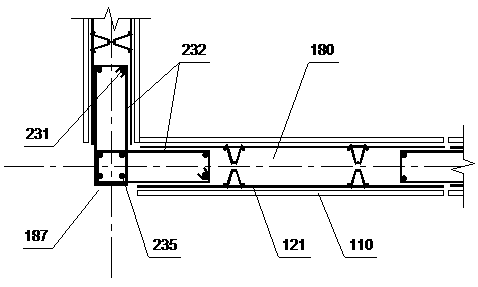

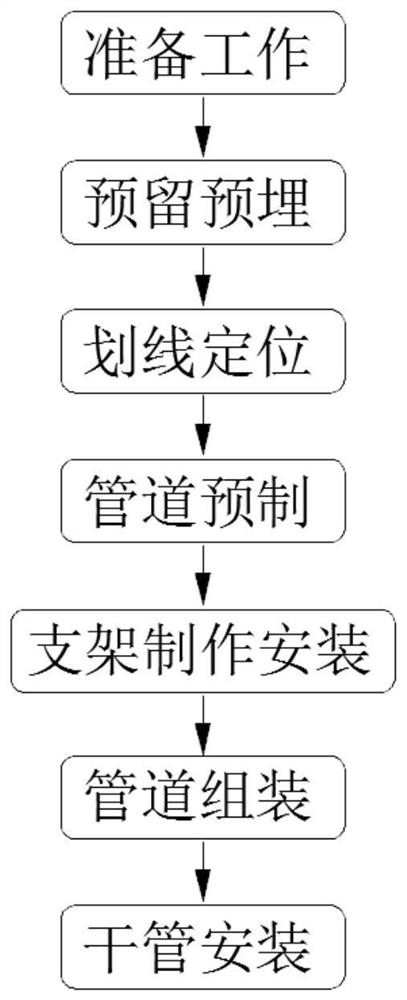

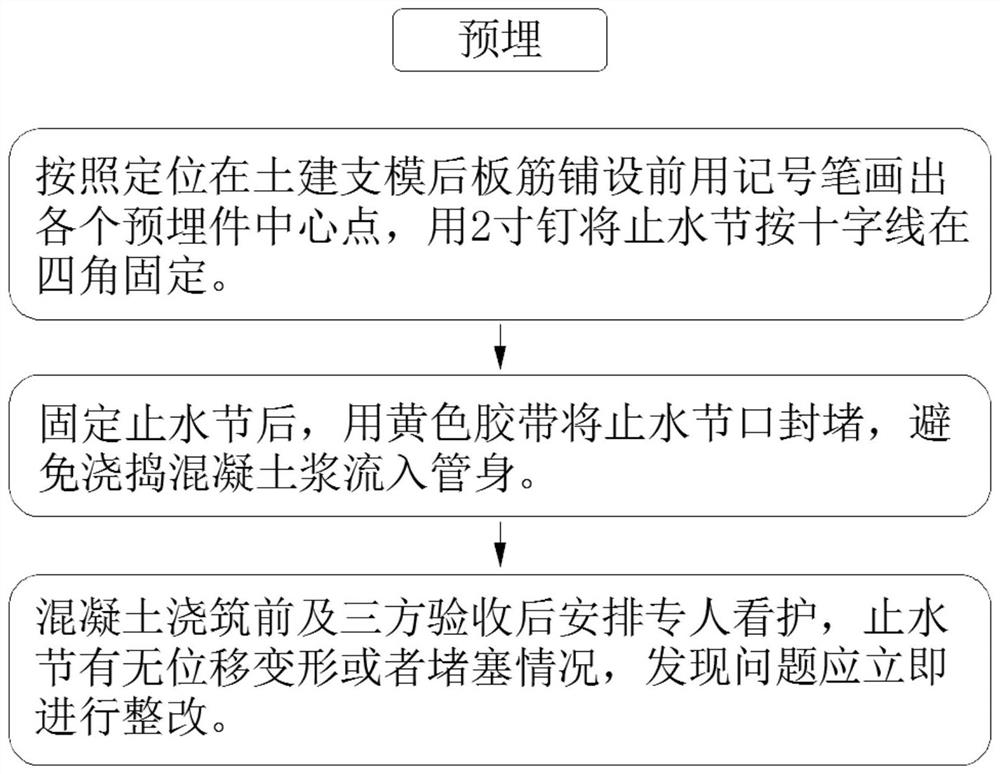

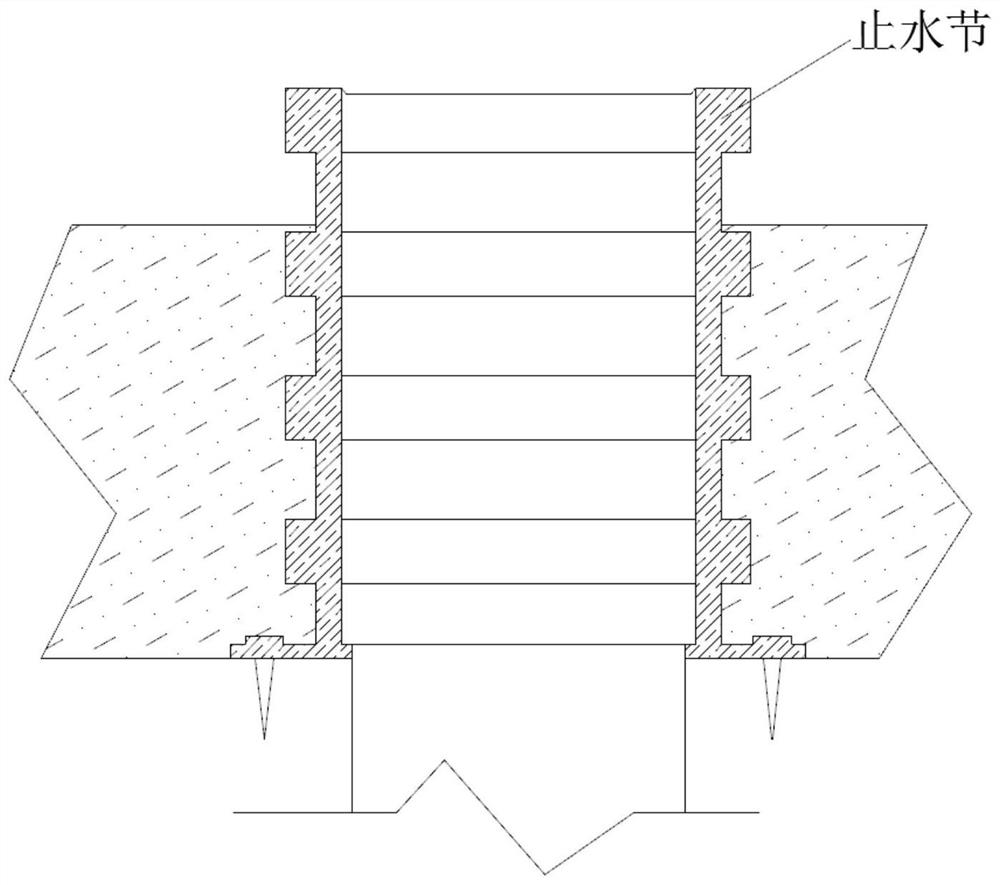

Construction method for modular toilet

PendingCN113136927ARealize programmatic operationInstallation quality is easy to controlPipe laying and repairDomestic plumbingArchitectural engineeringDrainage tubes

The invention discloses a construction method for a modular toilet, and belongs to the technical field of building construction. The method comprises the following steps of S1, conducting preparation work; S2, conducting reserving and pre-burying, specifically, setting pre-burying points during civil construction to be used for mounting pre-buried parts, and pouring concrete after the pre-buried parts are arranged; S3, conducting marking and positioning, specifically, planning the trend of drainage pipelines, and conducting positioning, mounting and marking on forms; S4, prefabricating pipelines; S5, manufacturing and mounting a support; S6, assembling the pipelines, specifically, assembling the main pipelines after the pipelines are produced and machined in a factory; and S7, mounting a trunk pipe, specifically, mounting the trunk pipe in field after the assembled main pipes are arranged on a hanging frame of the support. According to the method, the concrete is poured at a time through a pre-buried water stop joint, the waterproof performance of the toilet is improved, positioning and marking are conducted through a standard form, prefabricated drainage pipelines at different floors are assembled and arranged, programmed operation and mold positioning are achieved, the installation quality is easy to control, and the construction standard is improved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

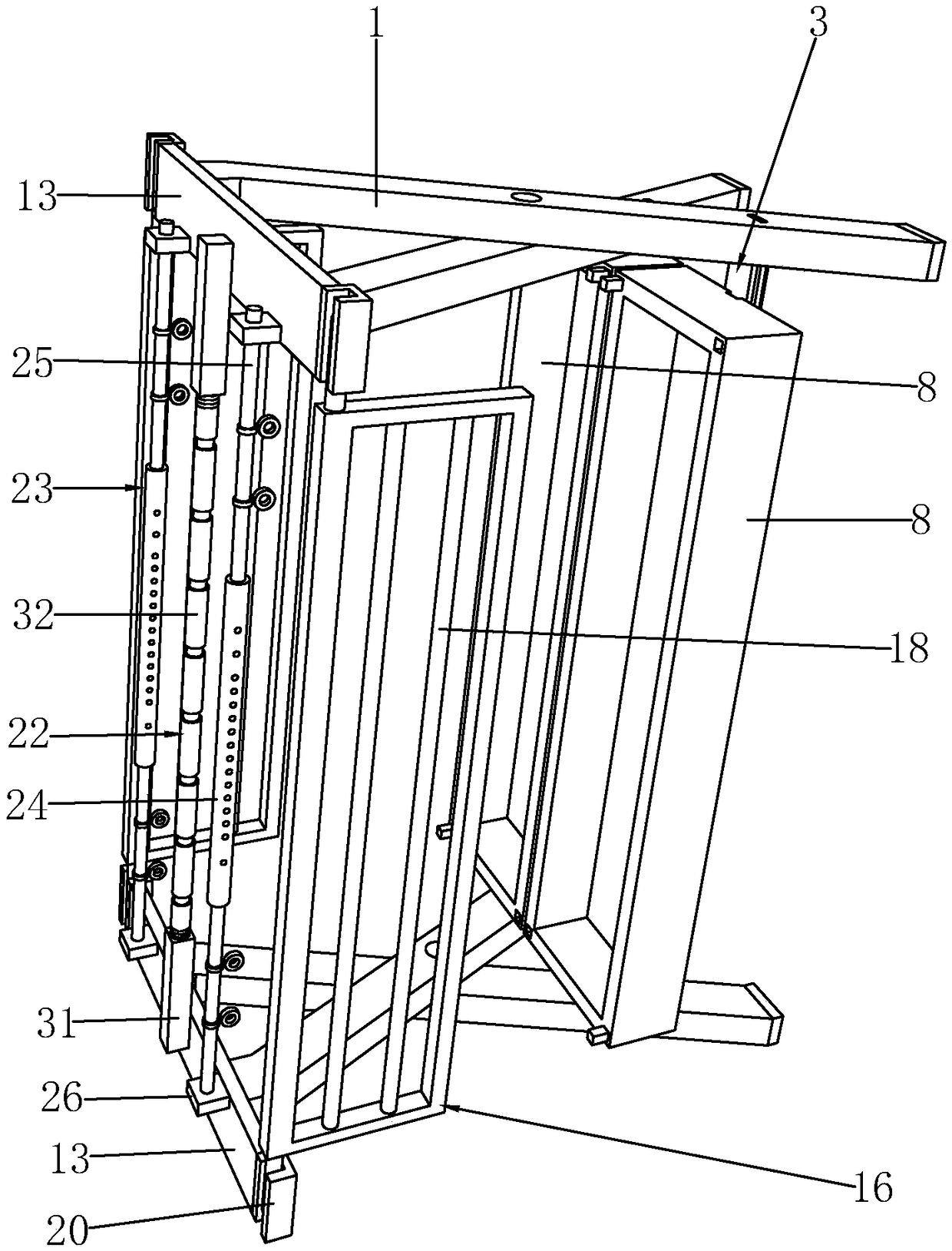

A device and method for monitoring the settlement of layered soil

The invention discloses a filing layered sedimentation monitoring device and method. The monitoring device comprises a bottom sedimentation monitoring unit, a middle sedimentation monitoring unit and a ground surface sedimentation monitoring unit which are buried in a soil layer to be monitored from bottom to top and are vertically arranged. Burying holes are formed in the soil layer to be monitored. An anchoring head is arranged under the bottom sedimentation monitoring unit. The bottom sedimentation monitoring unit, the middle sedimentation monitoring unit and the ground surface sedimentation monitoring unit are all provided with inclinometer pipes, extensible pipes arranged on the outer sides of the inclinometer pipes in a sleeving mode and displacement sensors installed on the upper portions of the inner sides of the inclinometer pipes. The monitoring method comprises the steps that firstly, drilling of the burying holes is conducted; secondly, the bottom sedimentation monitoring unit is installed; thirdly, the middle sedimentation monitoring unit is installed; fourthly, the ground surface sedimentation monitoring unit is installed; and fifthly, layered sedimentation monitoring is conducted. The filing layered sedimentation monitoring device and method are reasonable in design, convenient and easy to operate, convenient to bury, high in measuring precision and capable of effectively solving the problems that existing layered sedimentation monitoring equipment is large in equipment burying workload and low in measuring precision.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

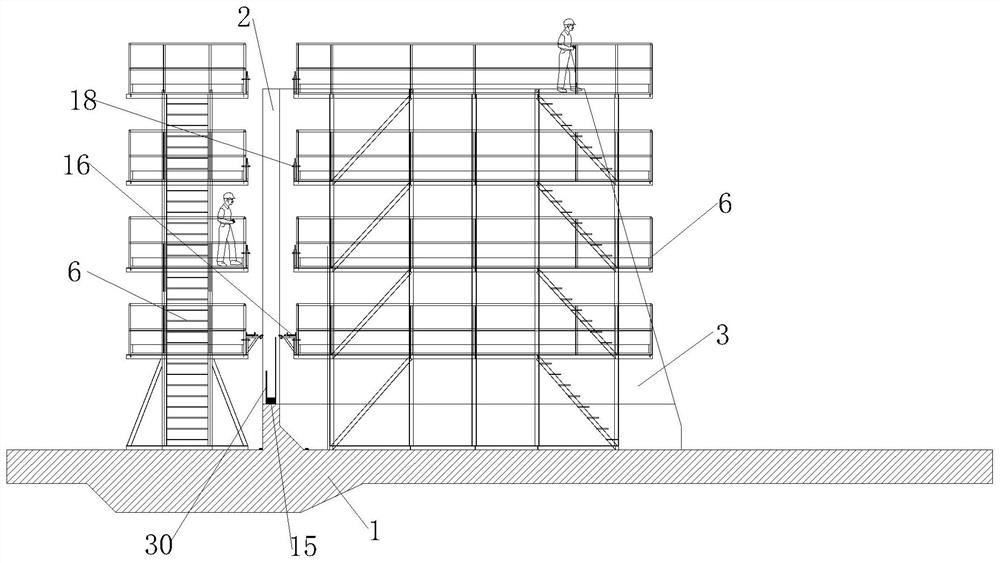

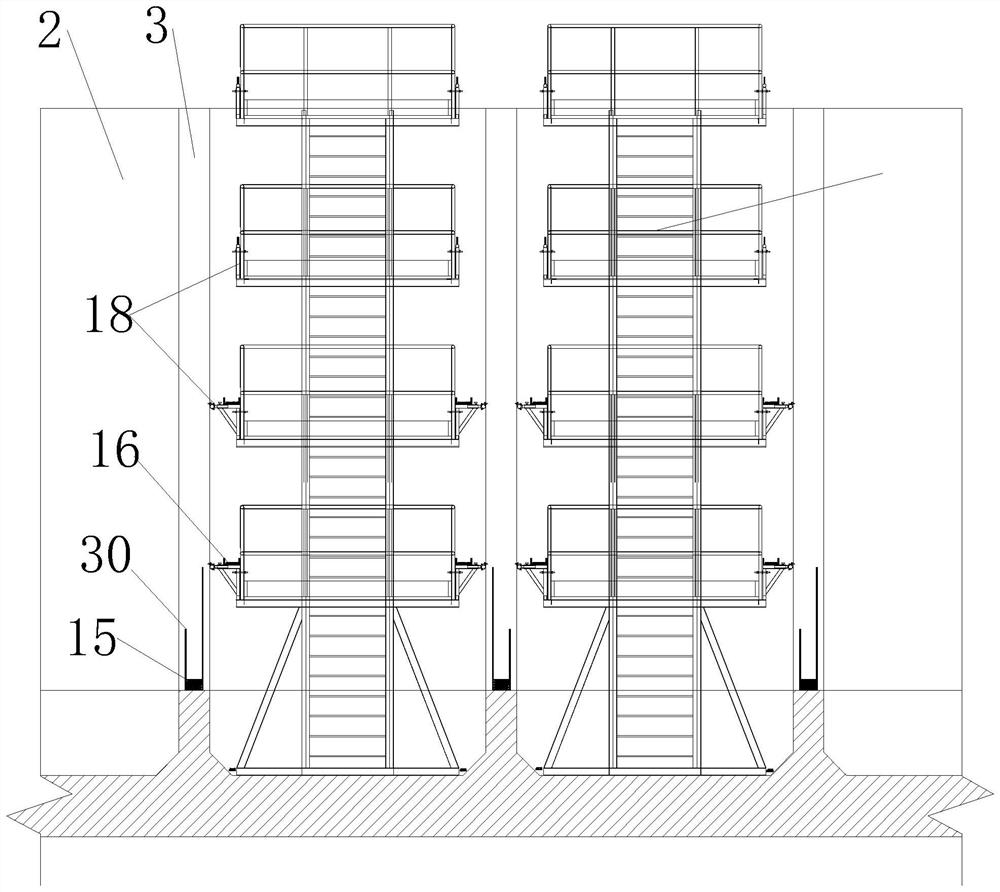

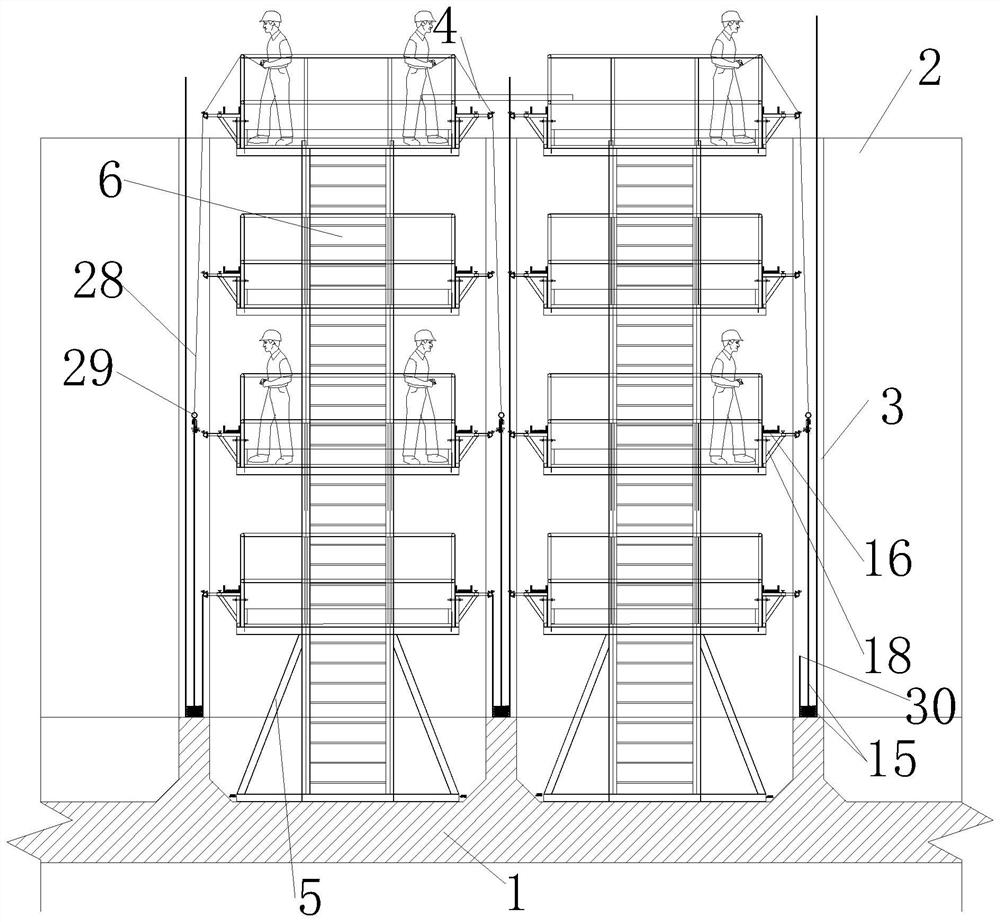

A kind of buttress type high wall steel reinforcement installation and construction system

ActiveCN114182962BRealize interconnectionImprove efficiencyDry-dockingArtificial islandsButtressArchitectural engineering

The invention discloses a buttress-type high-wall steel bar installation and construction system, comprising a buttress-type high-wall steel-bar installation operation platform and a steel tractor; One of the +2 operating sub-platforms is located on the inner side of the retaining wall, and N+1 operating sub-platforms of the N+2 operating sub-platforms are interspersed between the N buttress walls, and N is not A positive integer less than 2; auxiliary parts of the sample rack include auxiliary vertical rods, auxiliary horizontal rods, telescopic rods, sample frame fasteners and spacer columns; rebar pullers include strip steel plates, adjusting screws, butterfly nuts and traction rings. In the present invention, a positioning column for connecting a plurality of sample rack auxiliary parts is arranged on the outer side of the protective fence along the peripheral side of the protective fence. The vertical bars are pulled by the steel tractor, and multiple working surfaces work at the same time without interfering with each other.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com