Fire-resistant abrasion-proof inner lining structure for heat insulation surface of industrial furnace

A fire-resistant and wear-resistant, industrial furnace technology, applied in lining repair and other directions, can solve the problems of difficult construction quality control, cross fire, difficult maintenance, etc., and achieve the effects of easy control of installation quality, small quality difference, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

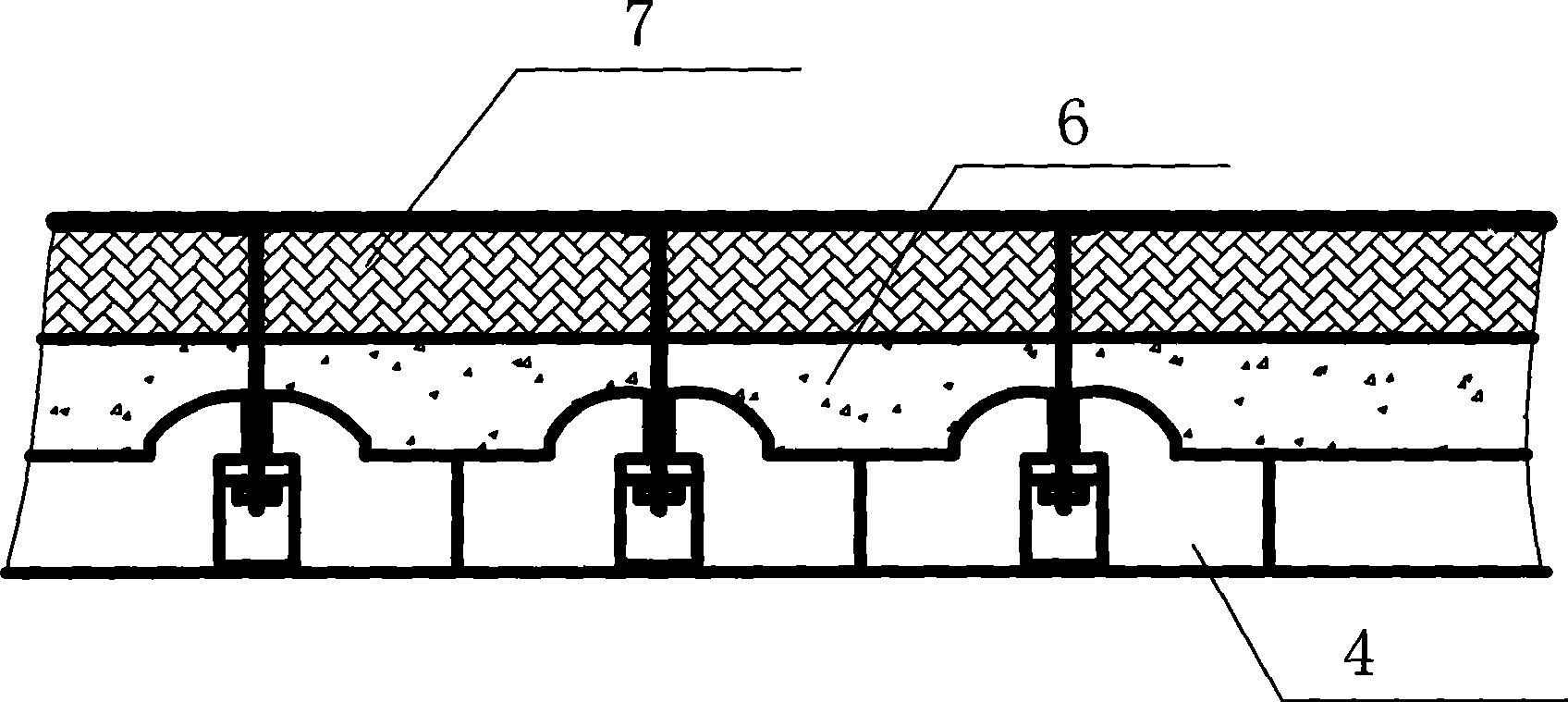

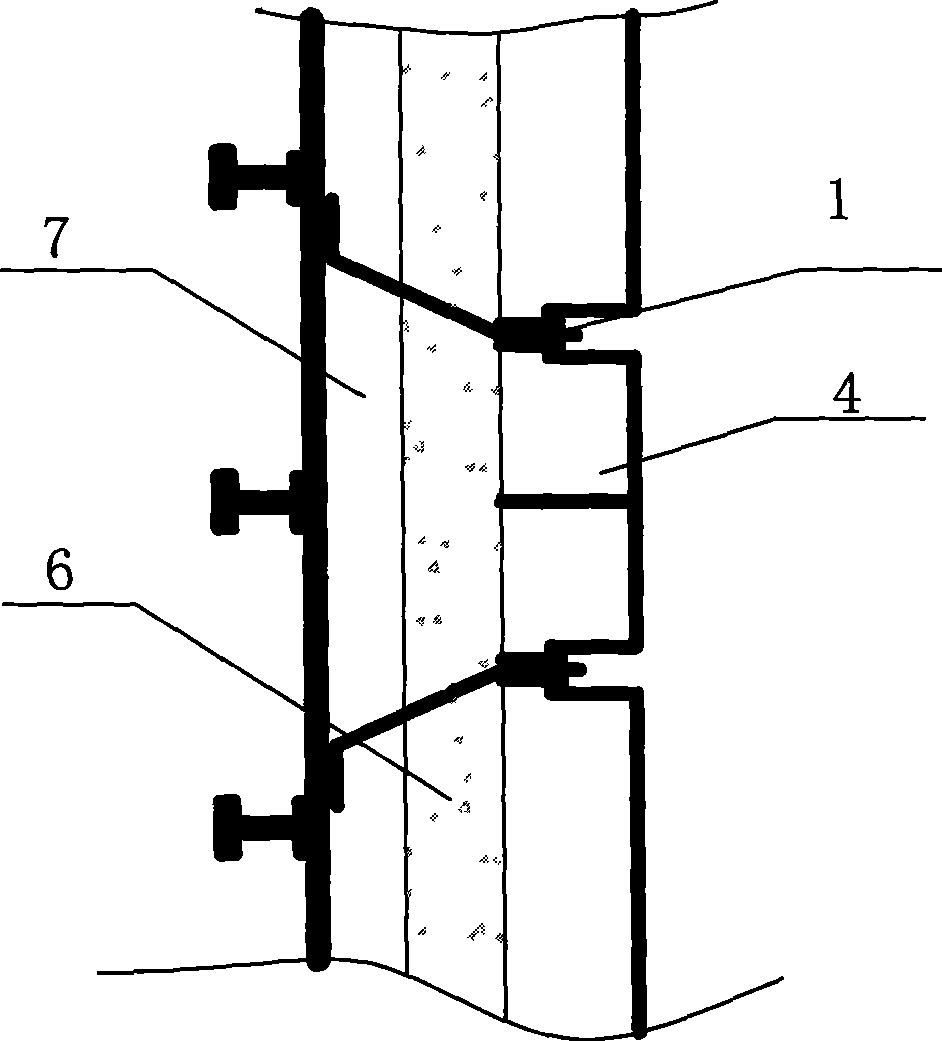

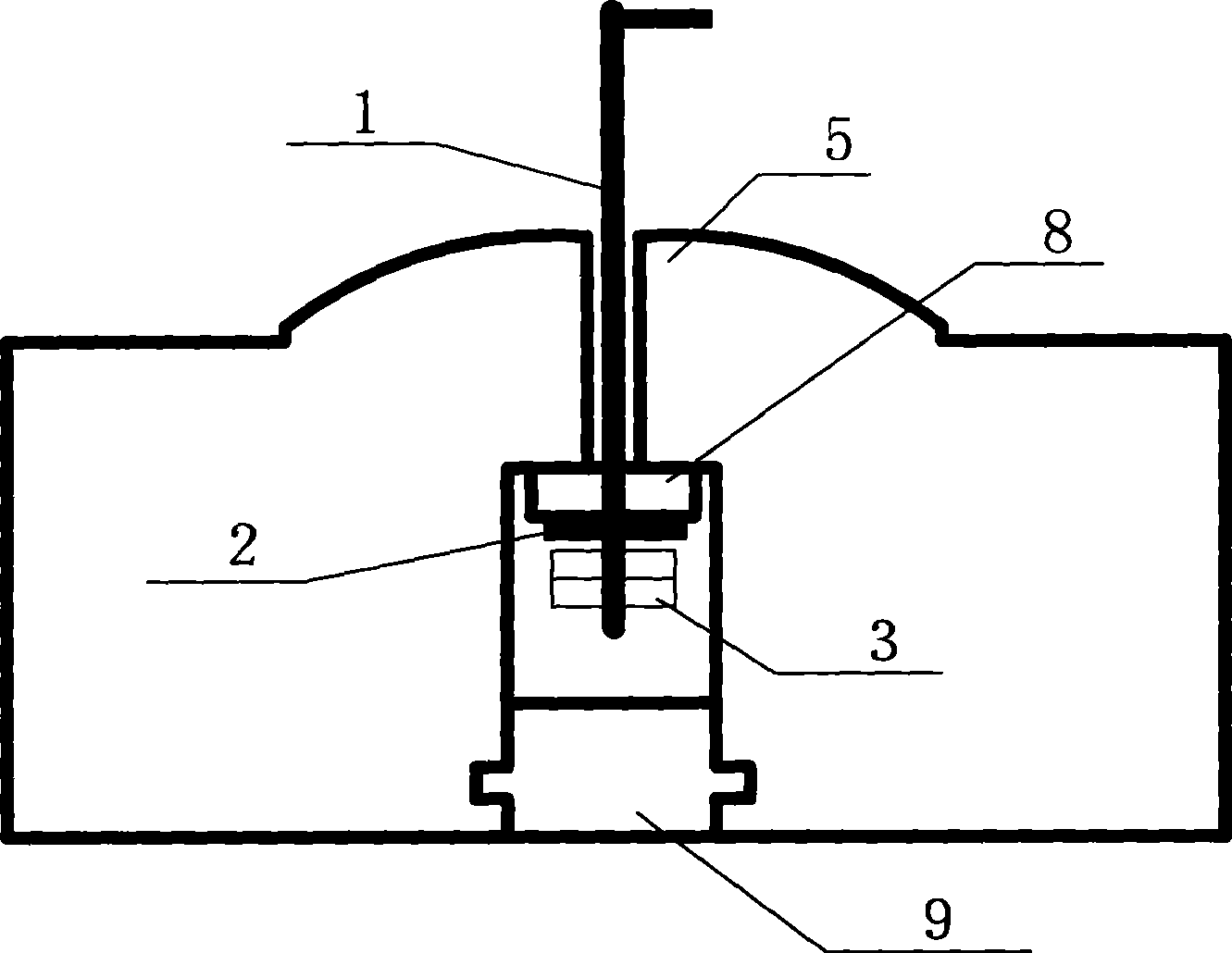

[0020] Such as Figure 1-Figure 3 As shown, first lay ceramic fiber bricks 7 and welded heat-resistant bolts 1 on the main support structure of the heat-insulating surface of the industrial furnace wall or furnace roof, then lay refractory and wear-resistant bricks 4, and then pour heat-insulating castables 6 on the inside, the present invention then It mainly includes heat-resistant bolts 1, heat-resistant flat pads 2, heat-resistant nuts 3 and wear-resistant bricks 4, wherein the refractory and wear-resistant bricks 4 are prefabricated, and there are stepped through holes 5 vertically in the refractory and wear-resistant bricks 4. The fastening end of the heat bolt 1 is L-shaped, which passes through the thermal insulation castable 6 and ceramic fiber brick 7 of the industrial furnace wall or roof, and is finally welded on the steel frame of the wall or furnace roof. The threaded end of the heat-resistant bolt 1 Pass through the stepped through hole 5 of the wear-resistant b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com