A processing technology of high-strength and low-creep pvc energy-saving frame

A processing technology and low-creep technology, which is applied in the processing technology field of high-strength and low-creep PVC energy-saving attached frame, can solve the problems of easy deformation, obvious thermal expansion and cold contraction of plastic attached frame, and low dimensional change rate. Installation quality easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

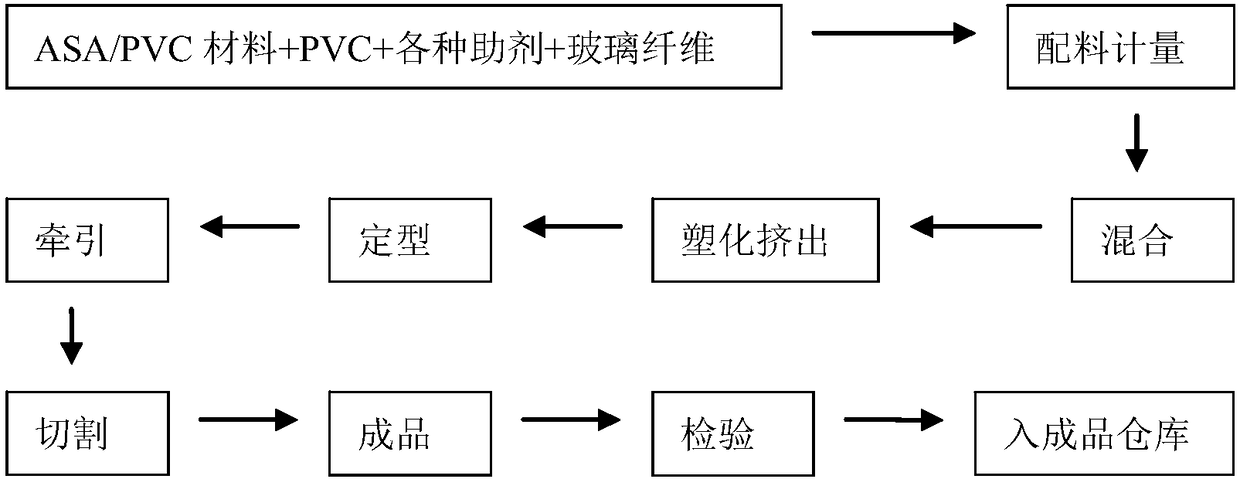

Method used

Image

Examples

Embodiment 1

[0024] The production of the attached frame material consists of the following raw materials in parts by weight: 100 parts of ASA / PVC material, 15 parts of PVC, 2 parts of processing aid, 2 parts of stabilizer, 1 part of titanium dioxide, 10 parts of calcium carbonate, and 0.1 parts of internal lubricant 0.1 part of external lubricant, 0.5 part of glass fiber yarn treated with silane-based sizing agent.

[0025] The energy-saving attached frame finally produced through this formula has a coefficient of thermal expansion and contraction of 15×10 -6 m / °C.

Embodiment 2

[0027] The production of the attached frame material consists of the following raw materials in parts by weight: 100 parts of ASA / PVC material, 30 parts of PVC, 3 parts of processing aid, 3 parts of stabilizer, 2.5 parts of titanium dioxide, 25 parts of calcium carbonate, and 0.5 parts of internal lubricant Parts, 0.5 parts of external lubricant, 10 parts of glass fiber filaments treated with silane-based sizing agent; and mix them.

[0028] The energy-saving attached frame finally produced through this formula has a coefficient of thermal expansion and contraction of 17.5×10 -6 m / °C.

Embodiment 3

[0030] The production of the attached frame material consists of the following raw materials in parts by weight: 100 parts of ASA / PVC material, 50 parts of PVC, 4 parts of processing aid, 4 parts of stabilizer, 4 parts of titanium dioxide, 40 parts of calcium carbonate, and 1 part of internal lubricant 1 part, 1 part of external lubricant, 20 parts of glass fiber filaments treated with silane-based sizing agent.

[0031] The energy-saving attached frame finally produced through this formula has a coefficient of thermal expansion and contraction of 21.3×10 -6 m / °C.

[0032] This shows that the formula component among the embodiment 1 can obtain best effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com