A kind of buttress type high wall steel reinforcement installation and construction system

A buttress-type and steel bar technology, applied in the field of buttress-type high-wall steel bar installation and construction system, can solve the problems of project construction progress, poor safety and reliability, and difficulty in steel bar installation, so as to speed up the overall construction progress, novel and reasonable design, Ease of use for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

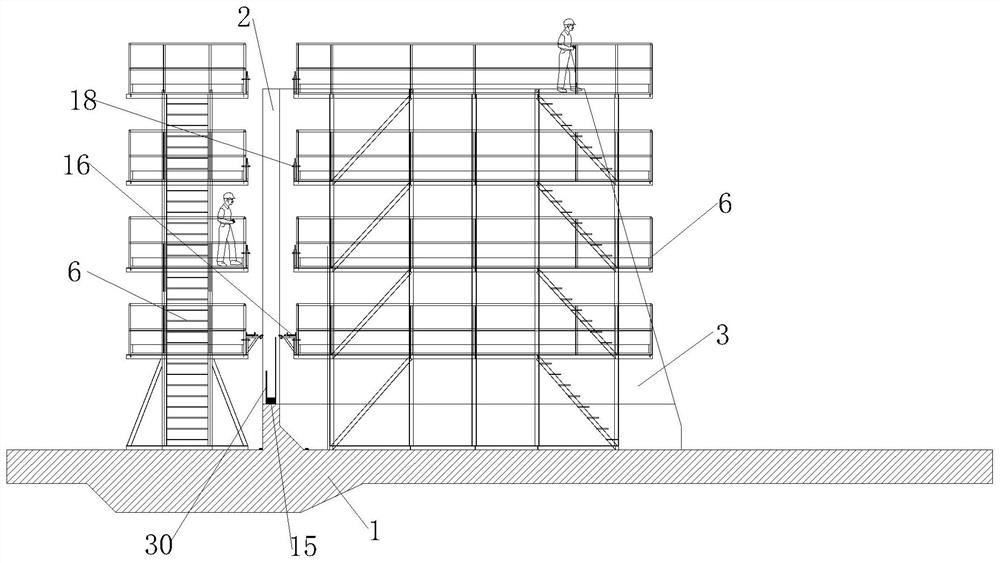

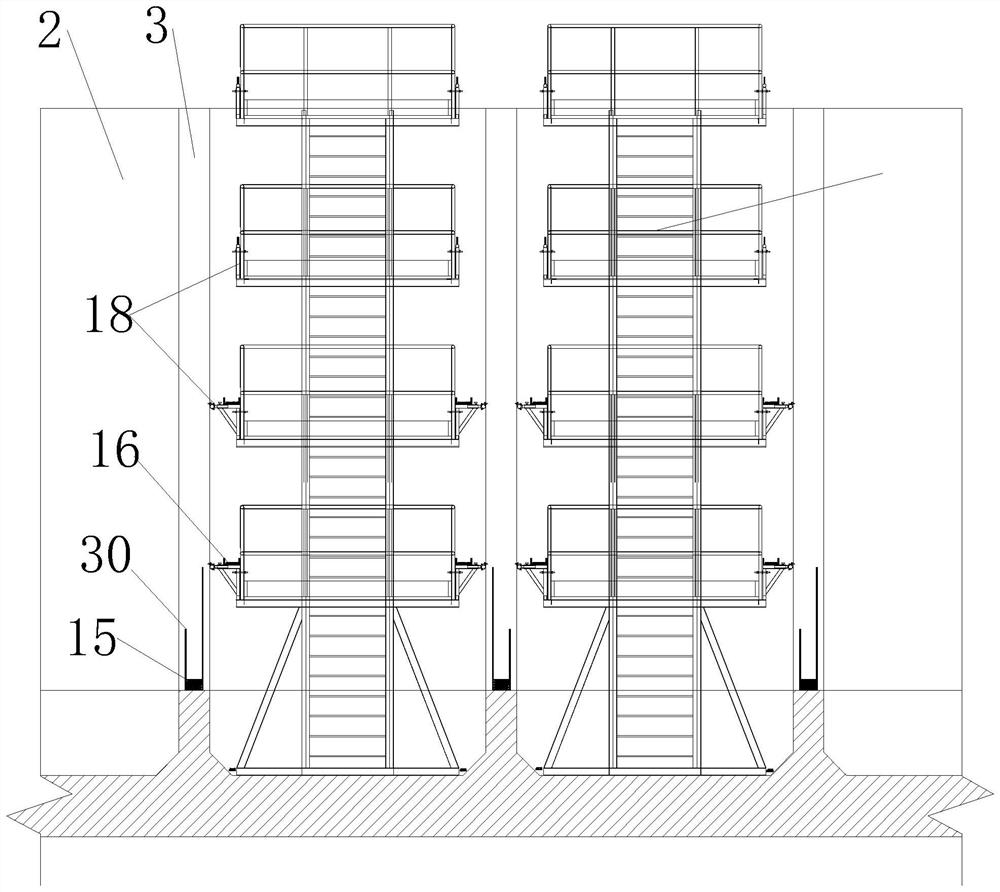

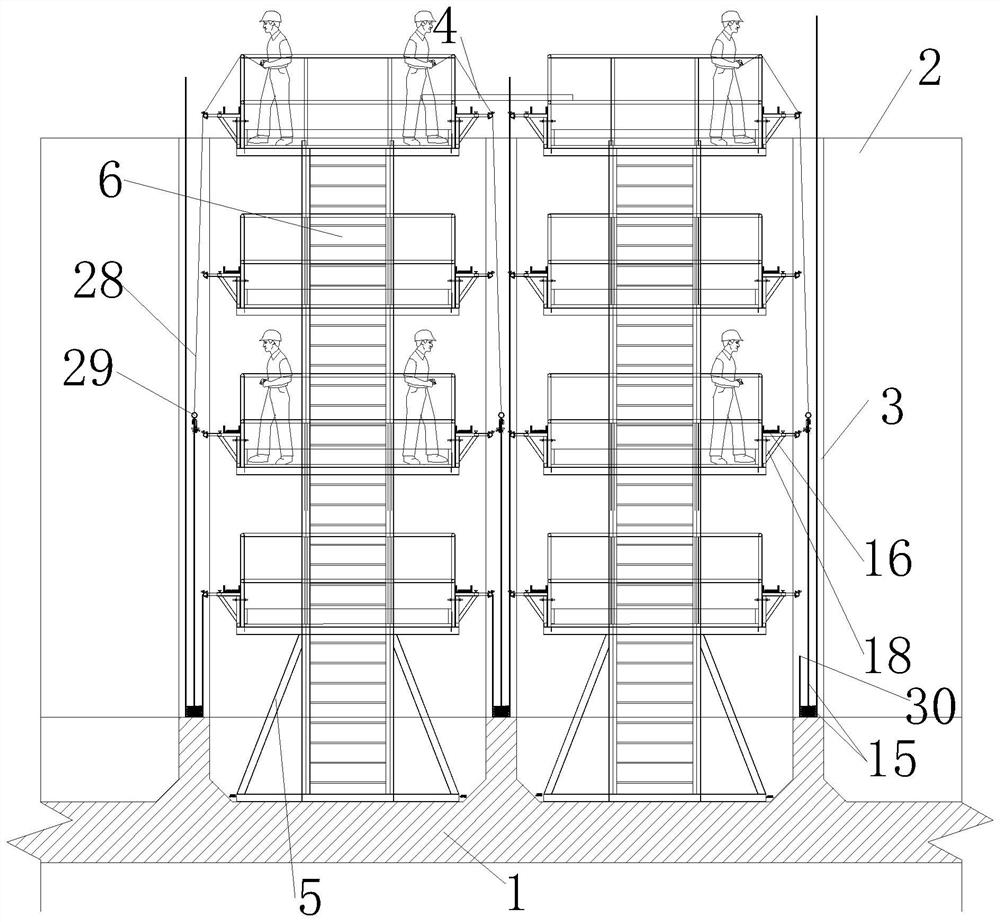

[0035] like Figure 1 to Figure 12 As shown, the present invention includes a buttress-type high-wall steel bar installation and operation platform and a plurality of steel bar tractors 29 for lifting the vertical bars 15;

[0036] The buttress type high wall steel reinforcement installation and operation platform includes N+2 operation sub-platforms 6, one of the N+2 operation sub-platforms 6 is located inside the retaining wall 2, and one of the N+2 operation sub-platforms 6 is located inside the retaining wall 2. N+1 operation sub-platforms 6 are interspersed between the N buttress walls 3 in a spaced manner. The operation sub-platform 6 includes a sub-platform base 5 and a multi-layer single operation layer arranged in sequence from bottom to top. The sub-platform base 5 includes The base plate 7, the single operation layer includes a plurality of interlayer uprights 9 and a layer support frame 10 fixedly arranged on the top of the plurality of interlayer uprights 9, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com