Disassembly-free formwork concrete shear wall structure building and construction method thereof

A technology of concrete shear wall and free formwork removal, which is applied in the direction of building structure, construction, structural elements, etc., can solve the problems of complicated operation, relatively large impact on building quality and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

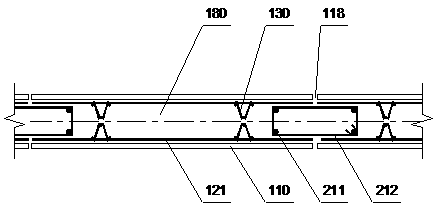

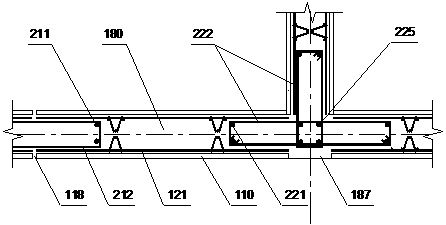

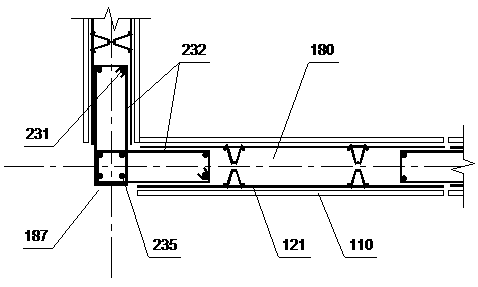

[0063] see Figure 1-4 , the shear wall body of the present invention adopts cast-in-place reinforced concrete structure, mainly consists of the shear wall solid formwork positioned at both sides of the shear wall body and the shear wall concrete layer poured between the shear wall solid formwork on both sides 180, the shear wall solid formwork adopts a steel bar truss solid formwork, the panel 110 of the steel bar truss solid formwork faces the outside of the wall, the steel bar truss faces the wall inner side, and the steel mesh and steel bar truss on the steel bar truss solid formwork Consolidated in the concrete layer of the shear wall. The steel truss solid formwork is used as the permanent formwork of the shear wall, and the steel bars and formwork that originally need to be arranged on the construction site are integrated in the factory. The production efficiency is high, the quality is good, and the on-site use is also very convenient. After completion, there is no ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com