Concrete shear wall structure and wall internal pipeline separated construction method

A concrete shear wall and construction method technology, applied in the direction of structural elements, walls, building components, etc., can solve the problems of destroying the wall structure, high labor intensity, affecting the performance of the wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

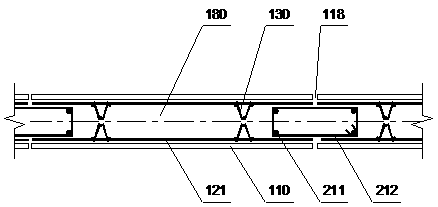

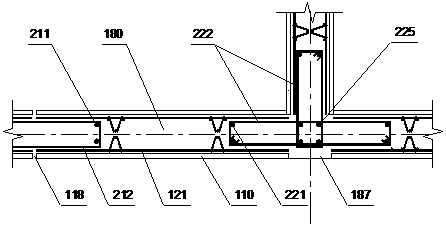

[0064] see Figure 1-13 , the construction method of the present invention comprises shear wall structure construction and pipeline construction in the wall, wherein the shear wall structure construction is used to build the wall body of the concrete shear wall structure, and the pipeline construction in the wall is used for building the shear wall In-wall pipelines are laid on the wall.

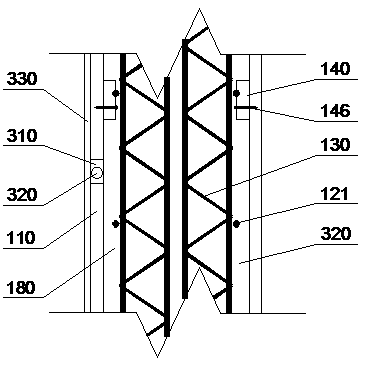

[0065] see figure 1 , in the construction of pipelines inside the wall, the main construction work includes slotting and wiring. Under the condition of not destroying the wall structure, the wall surface groove 310 for wiring is formed by cutting the panel, and then the groove 310 is formed in the groove Set the wire box or threading pipe 320 for wiring inside, or install the pipeline directly in the groove. After the wiring is completed, smooth the groove with putty or other viscous materials, or use sheets such as cloth, mesh, paper or wallpaper Paste it on the wall, cover the groove, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com