Half tenon riveting type aluminum plate connection device

A connecting device and aluminum plate technology, which is applied to building components, walls, buildings, etc., can solve the problems of affecting the appearance, disconnection, and inability to absorb thermal expansion and contraction of aluminum plates, etc., achieving good external visual effect, saving installation time, and easy installation quality The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

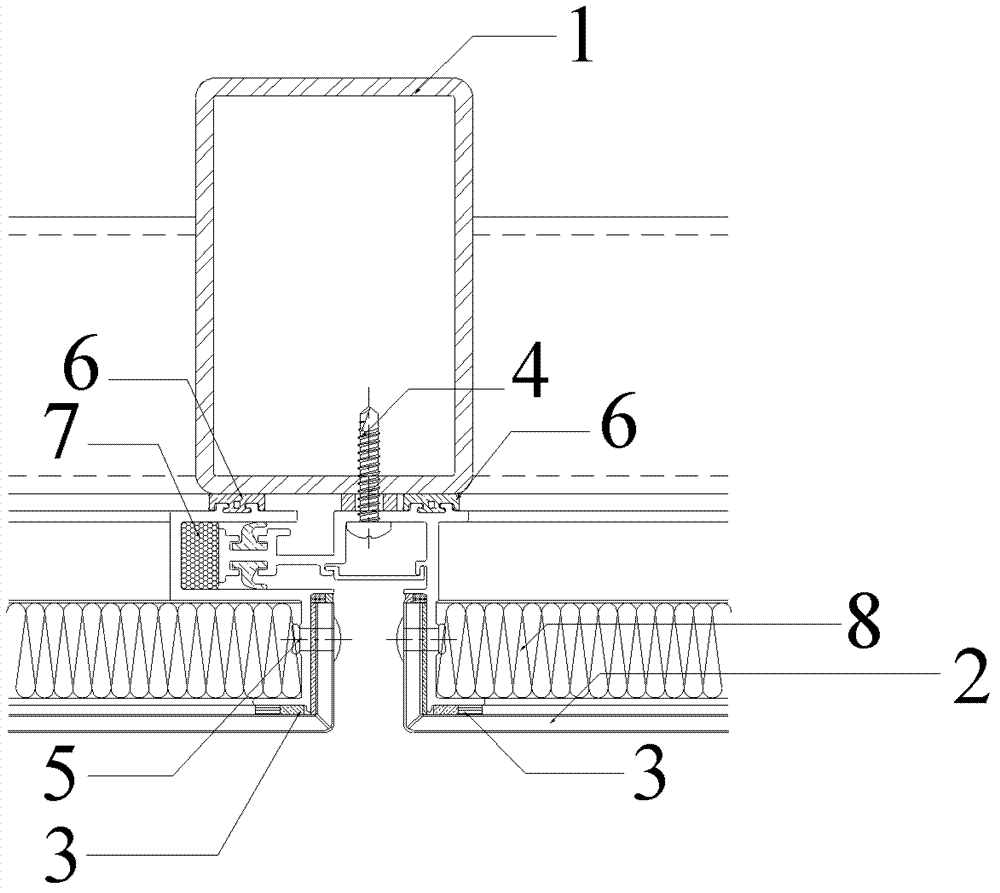

[0016] A semi-mortise and riveting aluminum plate connection device, its structure is as follows figure 1 As shown, the connecting device includes a galvanized square tube 1, an aluminum alloy cover plate 2 and a composite aluminum plate 3. The aluminum alloy cover plate 2 is arranged under the galvanized square tube 1 and connected to the galvanized square tube 1 by stainless steel self-tapping screws 4. For connection, there are two composite aluminum plates 3, which are horizontal L-shaped structures, symmetrically arranged under the aluminum alloy cover plate 2 and connected to the aluminum alloy cover plate 2 via aluminum rivets 5. The joint between the galvanized square tube 1 and the aluminum alloy cover plate 2 is provided with a sealing strip 6 made of EPDM rubber, the inside of the aluminum alloy cover plate 2 is provided with a cross seal 7, and the upper part of the composite aluminum plate 3 is provided with insulation cotton 8. The contact position between the th...

Embodiment 2

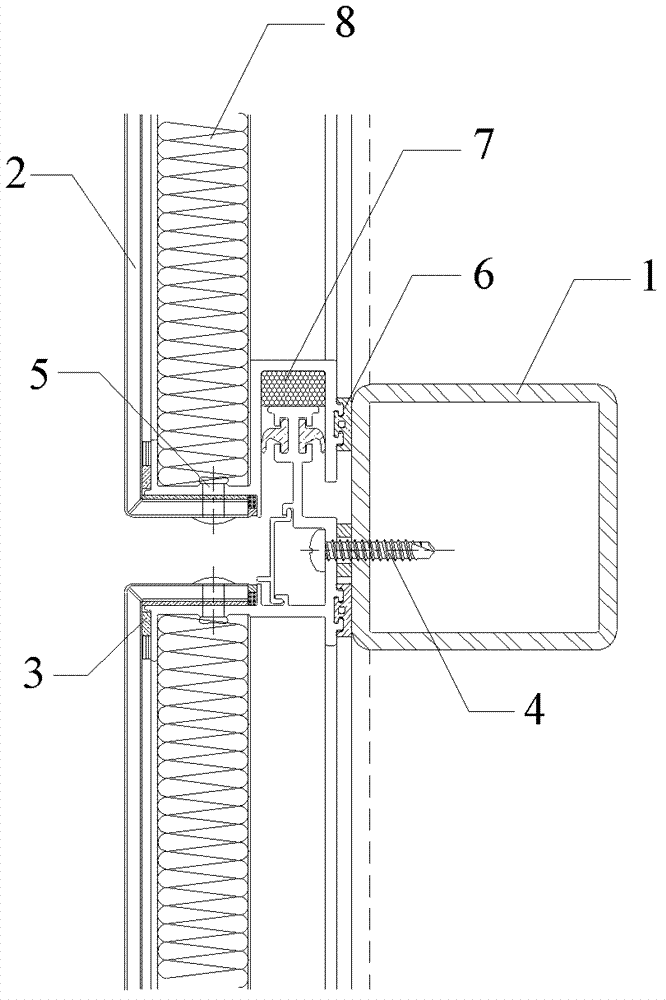

[0018] A semi-mortise and riveting aluminum plate connection device, its structure is as follows figure 2 As shown, the connection device includes a galvanized square tube 1, an aluminum alloy cover plate 2 and a composite aluminum plate 3, and the aluminum alloy cover plate 2 is arranged on the side of the galvanized square tube 1 and connected to the galvanized square tube by stainless steel self-tapping screws 4. 1 connection, two composite aluminum plates 3 are provided, which are vertical L-shaped structures, symmetrically arranged on the side of the aluminum alloy cover plate 2 and connected to the aluminum alloy cover plate 2 through aluminum rivets 5 . The joint between the galvanized square tube 1 and the aluminum alloy cover plate 2 is provided with a sealing strip 6 made of EPDM rubber, the inside of the aluminum alloy cover plate 2 is provided with a cross seal 7, and the upper part of the composite aluminum plate 3 is provided with insulation cotton 8. The contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com