Steel slag light partition wall, as well as preparation method and assembly process of light partition wall

A waste residue, lightweight technology, applied in the direction of walls, ceramic products, other household appliances, etc., can solve the problems of non-compliance with energy saving and environmental protection, increased structure size, high engineering cost, etc., and achieves easy control of installation quality, wide range of raw materials, and sound insulation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The steel mill waste slag lightweight partition wall of the present invention comprises 15-20% of slag, 7-8% of mineral powder, 8-10% of ceramsite, 6-8% of fly ash, and 1-3 additives in mass percentage. %, cement 25-30%, water 16-22%.

[0020] The steel mill waste slag lightweight partition wall of the present invention includes the steps of material preparation, material mixing and extrusion molding, specifically including:

[0021] A. Material preparation: crush and sieve slag, mineral powder, ceramsite, fly ash and cement respectively for later use;

[0022] B. Mixing: mix and stir the crushed and sieved raw materials and other raw materials according to the mass ratio to obtain a mixture;

[0023] C. Extrusion molding: the mixture obtained in step B is extruded through an extruder to obtain the target object.

[0024] The maximum particle size of the ceramsite in step A is not greater than 15mm.

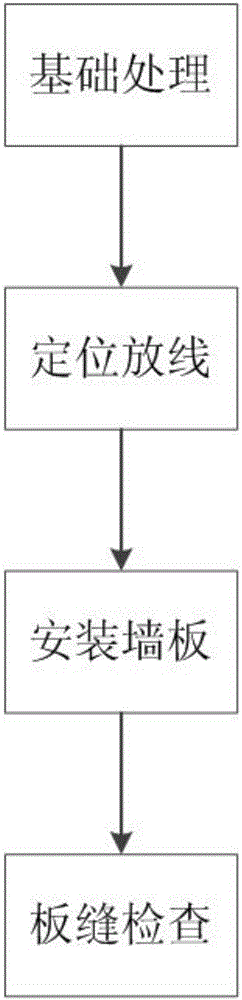

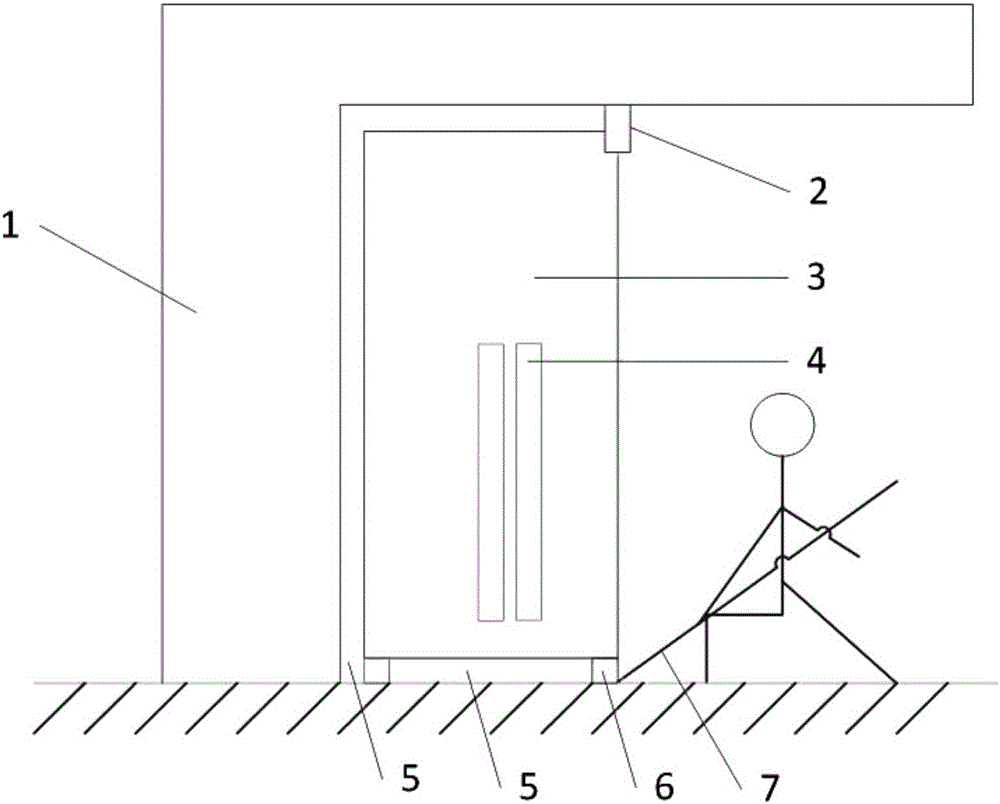

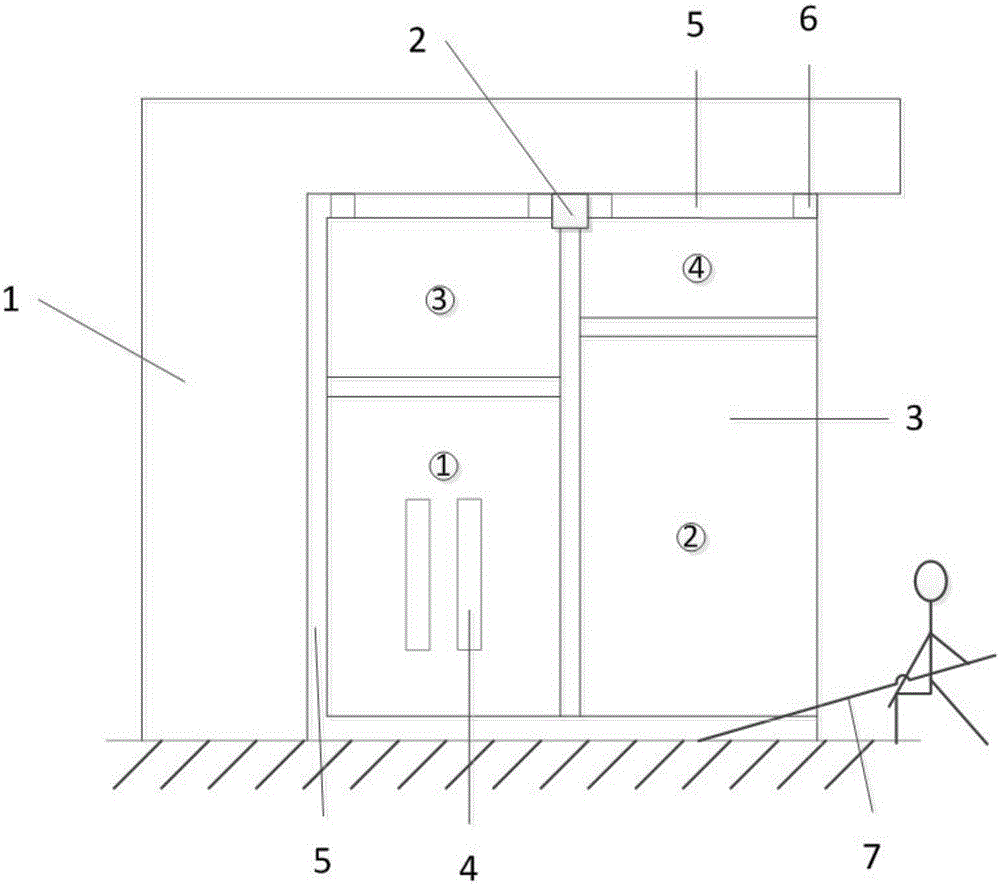

[0025] The installation process of the steel mill waste slag light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com