A pre-twisted anti-galling damping spacer

An anti-galling and spacer technology, which is applied in the field of spacer bars, can solve the problems of line safety, unsatisfactory effect, and unreachable anti-galling effect, and achieve the effects of optimizing damping characteristics, easy control of installation quality, and slowing down wire fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

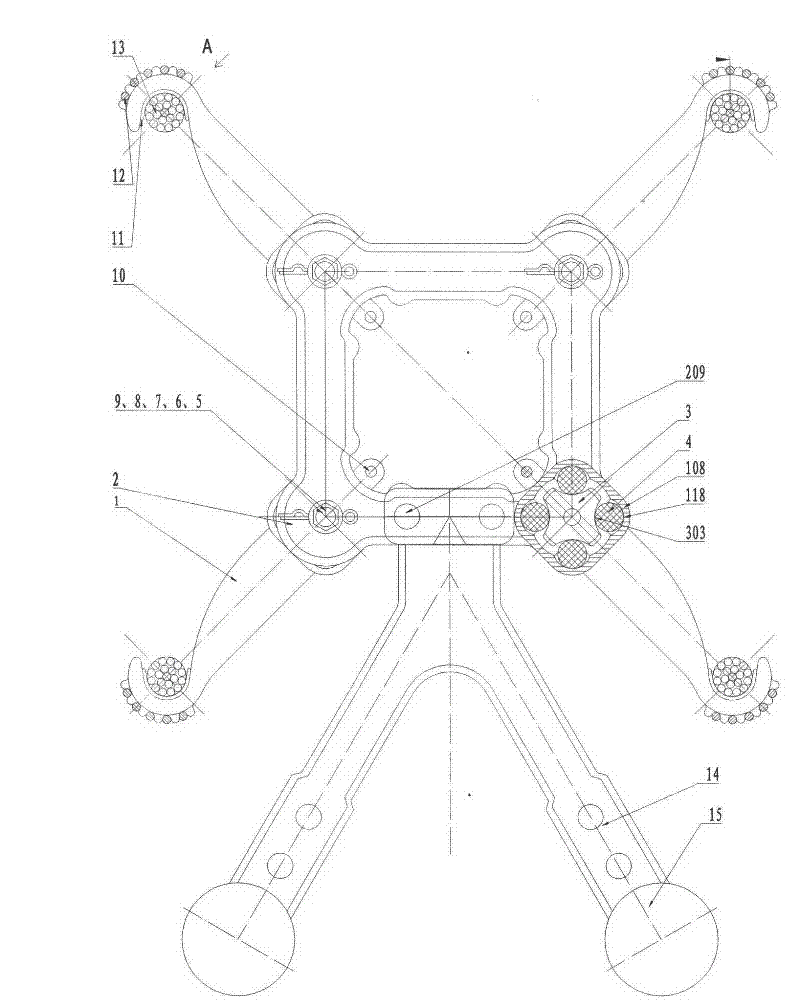

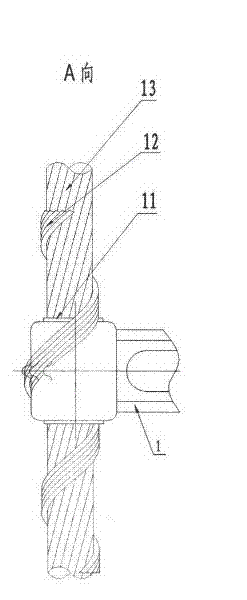

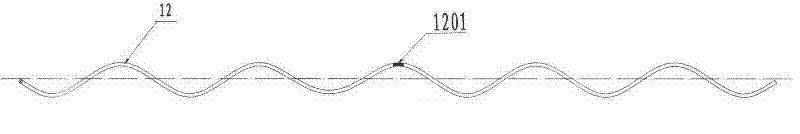

[0064] The present invention as Figure 1-23 As shown, it includes a bracket 2 and a wire clip 1, and the wire clip 1 is used to connect the split wire 13 by being arranged at the end corner of the bracket 2, and the wire clip 1 also includes a pre-twisted wire 12; the wire clip 1 is used for A hook 103 is formed at the head end of the connecting wire 13, and the back of the hook 103 is provided with a positioning structure for positioning the pre-twisted wire 12; The corners are connected by a damping limit device; the bottom of the middle position of the bracket 2 is fixedly connected with a herringbone pendulum device; the herringbone pendulum device includes a herringbone frame plate 14 and a spherical pendulum 15, and the herringbone frame The top end of the plate 14 is fixedly connected to the lower frame body at the middle position of the support 2 , and the spherical pendulum 15 is fixedly connected to the ends of the two feet of the herringbone frame plate 14 . The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com