Profile material reinforcement connecting structure part

A connection structure and profile technology, applied in the direction of connection components, shrinkage connection, thin plate connection, etc., can solve the problems of difficult to provide effective connection, fast connection, and thin-walled profiles can not be applied, so as to avoid energy loss, installation The effect of easy quality control and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

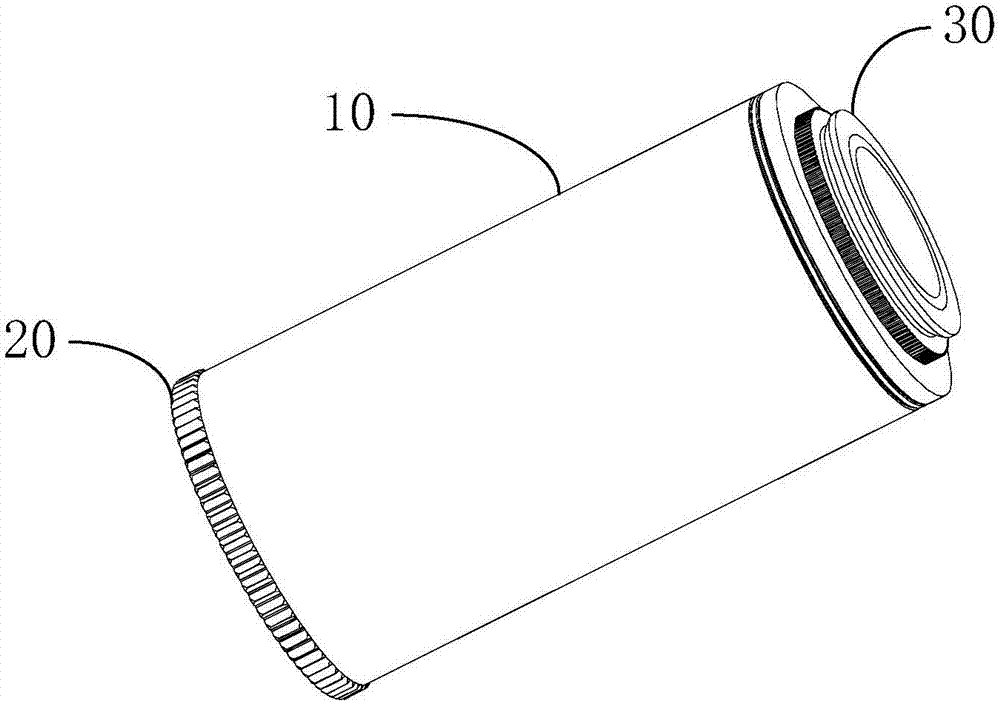

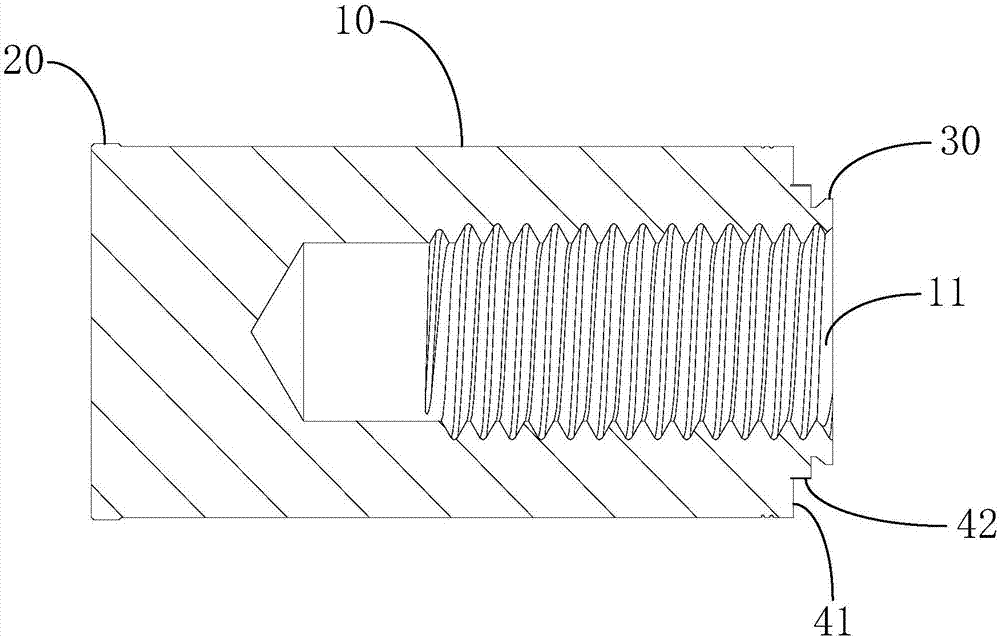

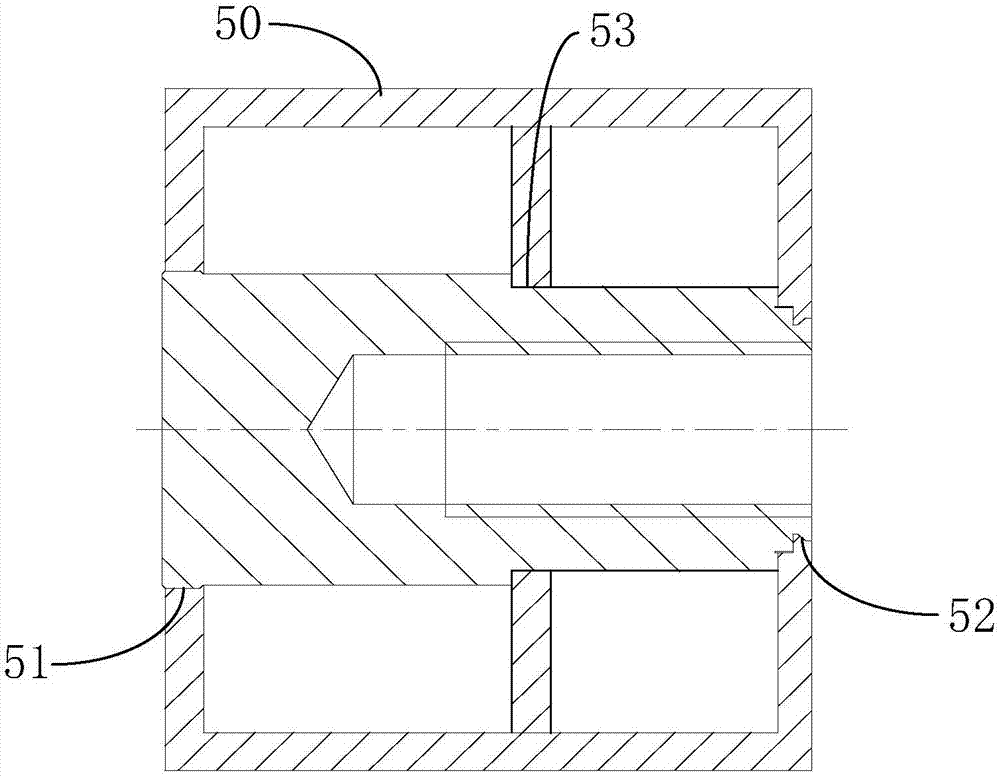

[0032] The profile reinforced connection structure provided by the present invention, such as Figure 1 to Figure 4 As shown, it is applied to the fastening connection of profiles 50 with at least two parallel facades, including a cylinder body 10, and one end of the cylinder body 10 is provided with first flower teeth 20 arranged circumferentially along the outer surface of the cylinder body 10 The other end of the barrel 10 is provided with an interlocking key 30 arranged along the circumferential direction, and the first spline 20 and the interlocking key 30 are respectively affixed to two parallel facades of the profile 50, At least one of the two ends of the barrel 10 is fixedly connected to the mating fitting 61 through a connecting piece. In the present invention, the first spline 20 is in interference connection with one elevation of the profile 50, and the interlocking key 30 realizes self-tightening with the other elevation of the profile 50 through the flow of mater...

Embodiment 2

[0039] Please focus on reference Figure 5 and Figure 6 The difference between this embodiment and Embodiment 1 is that the axial hole 11 adopts double-sided blind holes at both ends, that is, the cylinder body 10 is respectively provided with a first blind hole 12 and a second blind hole 13 that are not connected, so that , through the first blind hole 12 and the second blind hole 13, the profile 50 can be connected to the pair of fittings 61 on both sides respectively. Of course, the axial hole 11 can also be a threaded through hole, an optical blind hole, an optical through hole, a half-threaded hole, a stepped hole without a thread, etc., as long as the connection with the connector can be realized.

Embodiment 3

[0041] Please focus on reference Figure 7 and Figure 8 The difference between this embodiment and Embodiment 1 is that: at least one of the two ends of the cylinder body 10 is provided with a connecting rod 14 extending in the axial direction, and the connecting rod 14 is a polished rod or a threaded rod, in other words, In this embodiment, the connection between the cylinder body 10 and the pair of fittings 61 is completed through the connecting rod 14 , of course, the corresponding connecting piece can be replaced with a matching nut or the like.

[0042] In summary, the profile reinforced connection structure provided by the present invention is applied to the fastening connection of profiles 50 with at least two parallel facades, and includes a cylinder 10, one end of which is provided along the cylinder. 10, the first tooth 20 arranged circumferentially on the outer surface; the other end of the barrel 10 is provided with an interlocking key 30 arranged along the circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com