Cylinder assembled steel lead damper

An assembled and damper technology, which is applied in the direction of building components, earthquake resistance, etc., can solve the problems of general force effect, inconvenient installation and connection, and complicated construction technology, so as to achieve high material utilization rate, controllable installation quality, and strong good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The detailed structure of the present invention is described in conjunction with specific embodiments.

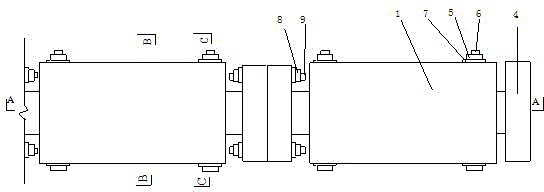

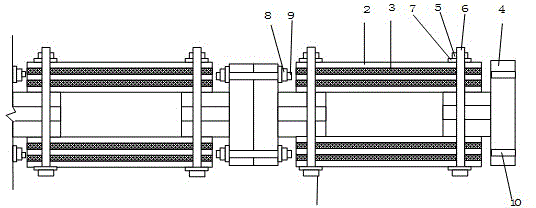

[0027] Such as figure 1 , 2 , 3 and 4, the damper includes at least two groups of cylinder-assembled steel-lead damper units, and each group of cylinder-assembled steel-lead damper units is connected in series.

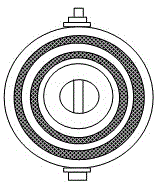

[0028] Each group of cylindrical assembled steel-lead damper units includes a cylindrical energy dissipation body 1 and a connecting piece 4; the cylindrical energy dissipation body 1 includes a lead cylinder 3 and a soft steel cylinder 2, and the outer side of the lead cylinder 3 is nested with a soft steel cylinder 2, and the connecting piece 4 is set at both ends of the cylindrical energy dissipation body 1, such as Figure 5 , 7 As shown in and 8, the longitudinal section of the connector 4 is T-shaped, and the connector 4 is provided with a screw hole 10, and the lead cylinder 3, the mild steel cylinder 2 and the connector 4 are fixed by the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com