Method for prefabricating equipment foundations and effectively fixing equipment foundations

A technology for equipment foundation and fixtures, applied in infrastructure engineering, construction, etc., can solve problems such as inability to connect pipes in prefabricated computer rooms, affect the appearance, and equipment installation is not in the middle, so as to achieve controllable installation quality, save construction time, and ensure accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

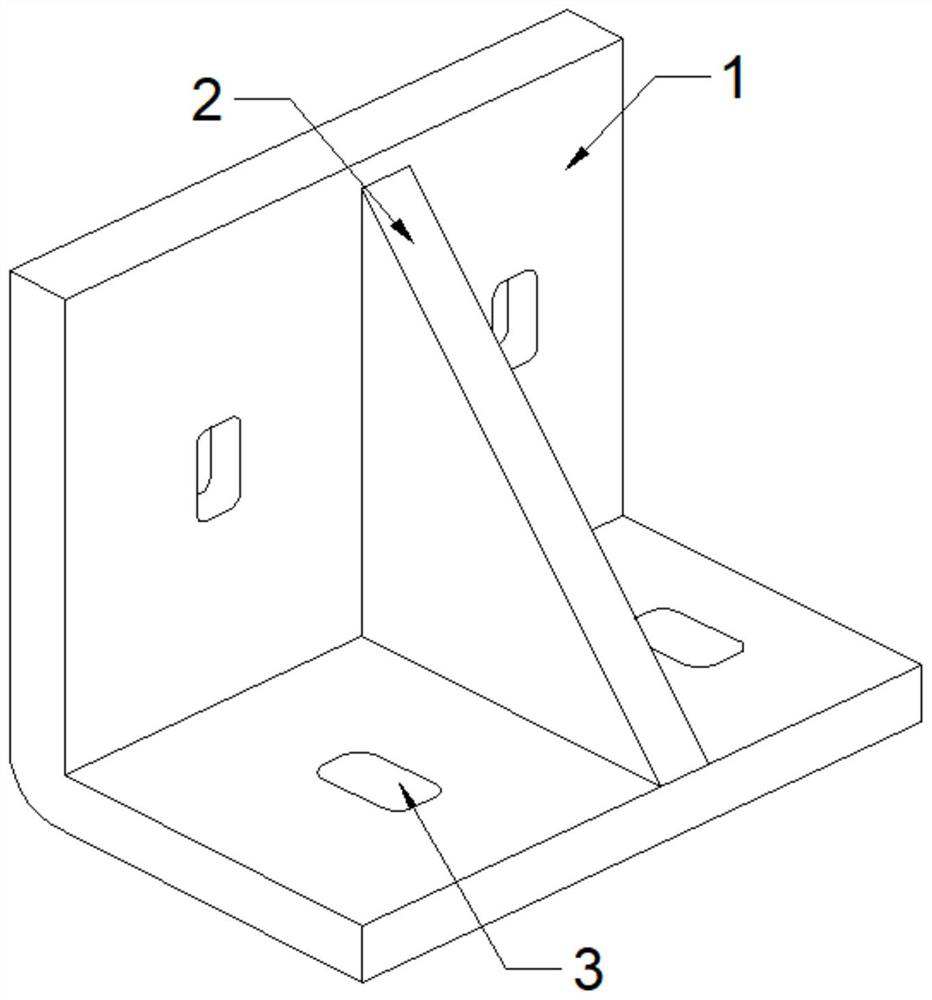

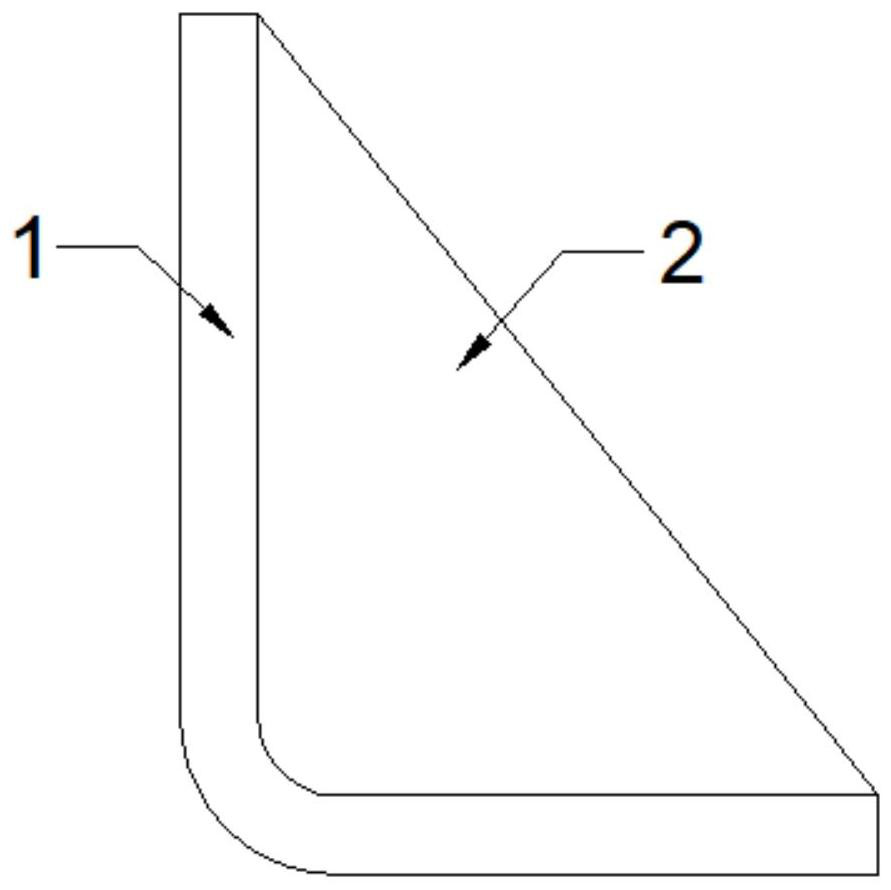

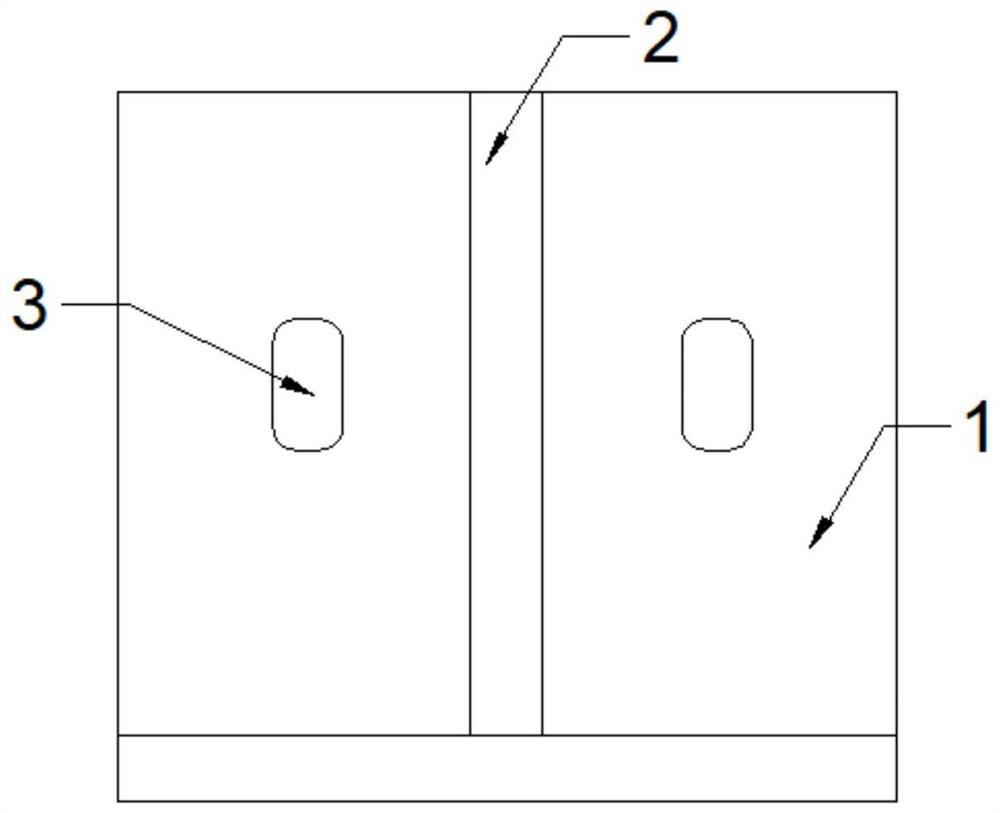

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0033] A method for prefabricating equipment foundations and effectively fixing them, the method steps are as follows:

[0034] S1: Deepen the design and produce drawings, use BIM technology, fully consider the construction and installation, energy saving and environmental protection, operation and maintenance and other factors to deepen the design of the pipeline and equipment foundation in the computer room, and design a humanized, intelligent, green and energy-saving high-precision computer room model, Export equipment foundation size positioning drawings;

[0035] S2: Prefabricate the equipment foundation, establish a prefabrication processing base or entrust a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com