Building of steel frame and concrete shear wall structure and construction method for building of steel frame and concrete shear wall structure

A concrete shear wall and steel frame technology, which is applied in the direction of building structure, construction, structural elements, etc., can solve the problems of high labor intensity, difficulty in arranging pipelines, and affecting the strength of walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

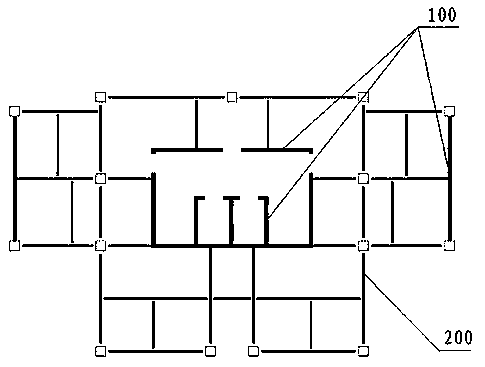

[0067] see figure 1 , the steel frame-concrete shear wall structure building includes a steel frame structure 200 and a shear wall body 100 arranged in the steel frame structure, and the arrangement of the shear wall body in the steel structure is based on the steel structure The connection method may be based on the existing technology, may include a core tube, may include a single piece shear wall or a corner shear wall, and the like.

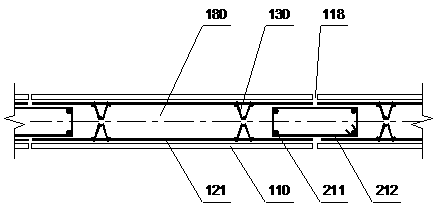

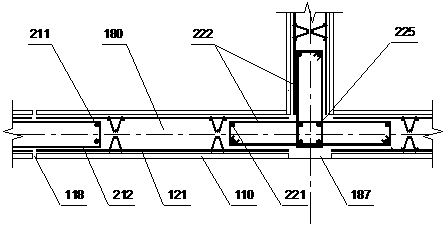

[0068] see Figure 2-5 , The shear wall in the steel frame-concrete shear wall structure building adopts the cast-in-place reinforced concrete structure, which is mainly composed of the shear wall solid formwork on both sides of the shear wall body and the shear wall solid formwork poured on both sides. The shear wall concrete layer 180 between them is composed of a steel bar truss solid formwork, the panel 110 of the steel bar truss solid formwork faces the outside of the wall, the steel bar truss faces the wall inside, and the steel bar tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com