Split-type glass guide rail structure for car door and fixing method thereof

A technology of glass guide rails and fixing methods, which is applied in the installation of windshields and window glass, vehicle components, etc., and can solve the problems of door appearance matching, cost, high mold precision requirements, and high product scrap rate that affect the NVH performance of the whole vehicle. , to achieve the effect of easy control of installation quality, good appearance and easy control of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

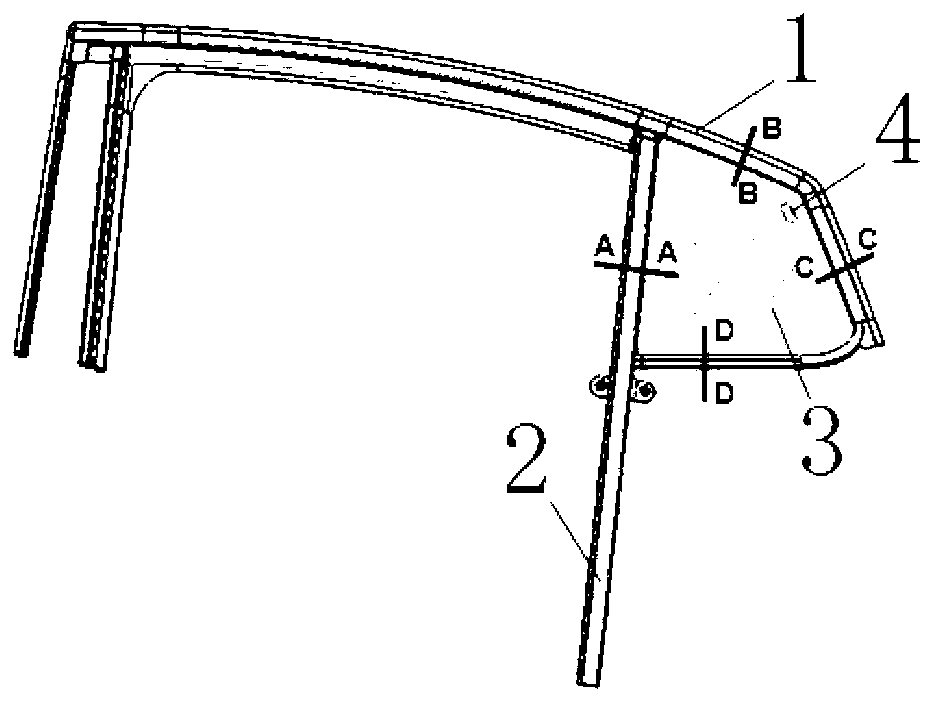

[0034] Such as figure 1 and figure 2 As shown, it is the assembly assembly of the guide rail structure. The rear guide rail 2, the upper glass run channel 1, and the four-corner window glass 3 are made separately and then assembled together easily. The four-corner window glass 3 is arranged between the rear guide rail 2 and the upper glass run channel 1. And in the rear portion of the upper glass run channel 1 corresponding to the positioning hole on the door sheet metal is provided with a positioning buckle 4.

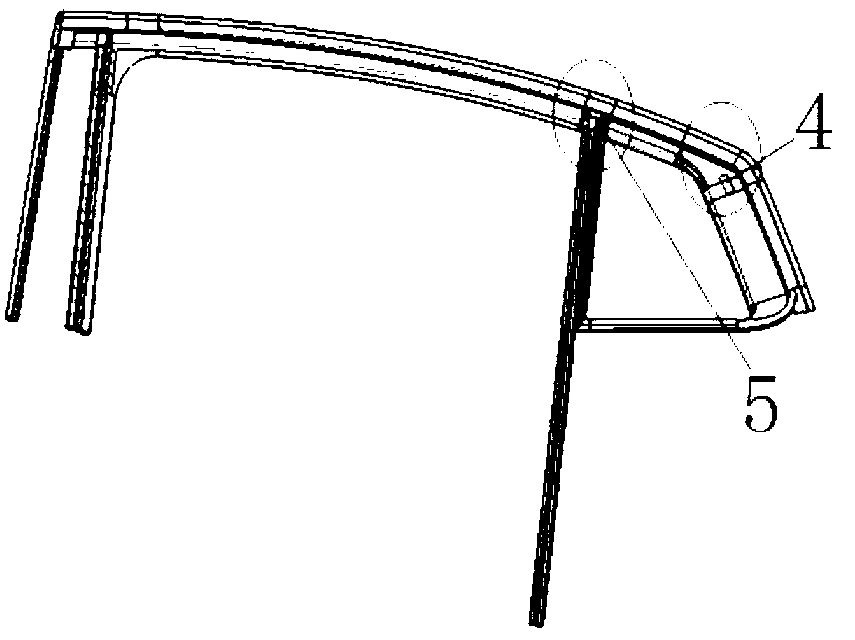

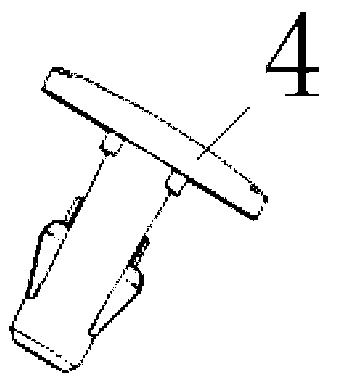

[0035] Such as image 3 and Figure 4 As shown, the positioning buckle 4 is a plastic clip, which is easy to install; the upper glass run channel 1 is provided with a slot, and the joint 5 between the upper glass run channel and the rear guide rail is where the top of the rear guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com