Integral slide device and method of floor steel pipe column bracket of bridge end bay closure section construction

A steel tube column support and integral sliding technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult operation of mechanical equipment, long time period, large material loss, etc., and save the disassembly and assembly procedures of supports , saving investment, and the effect of small safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

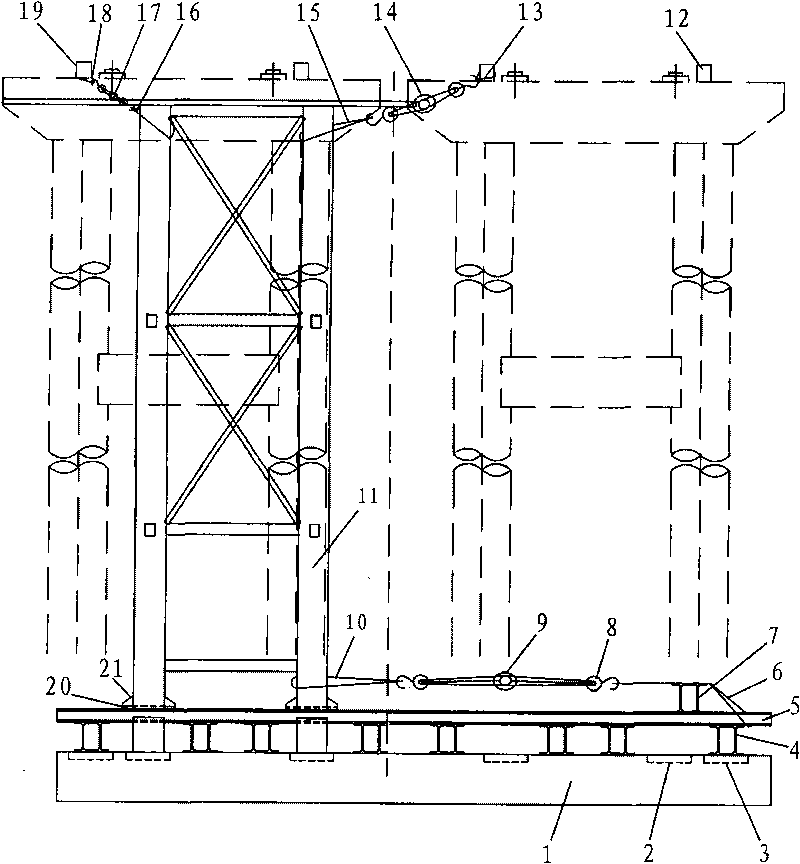

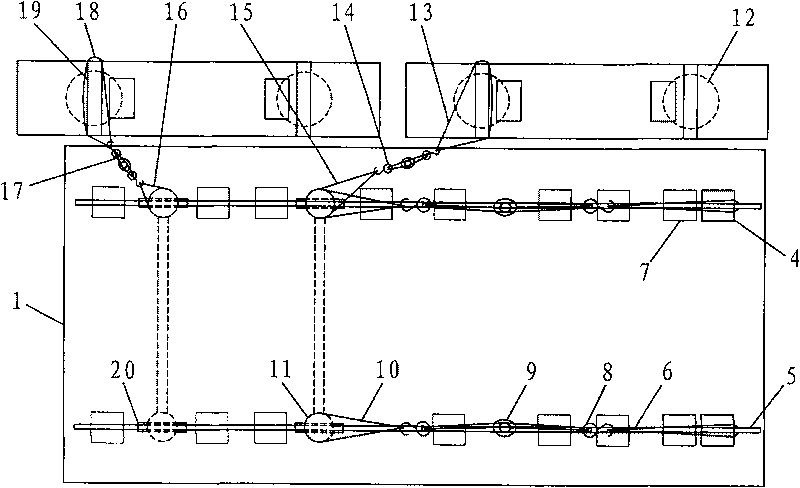

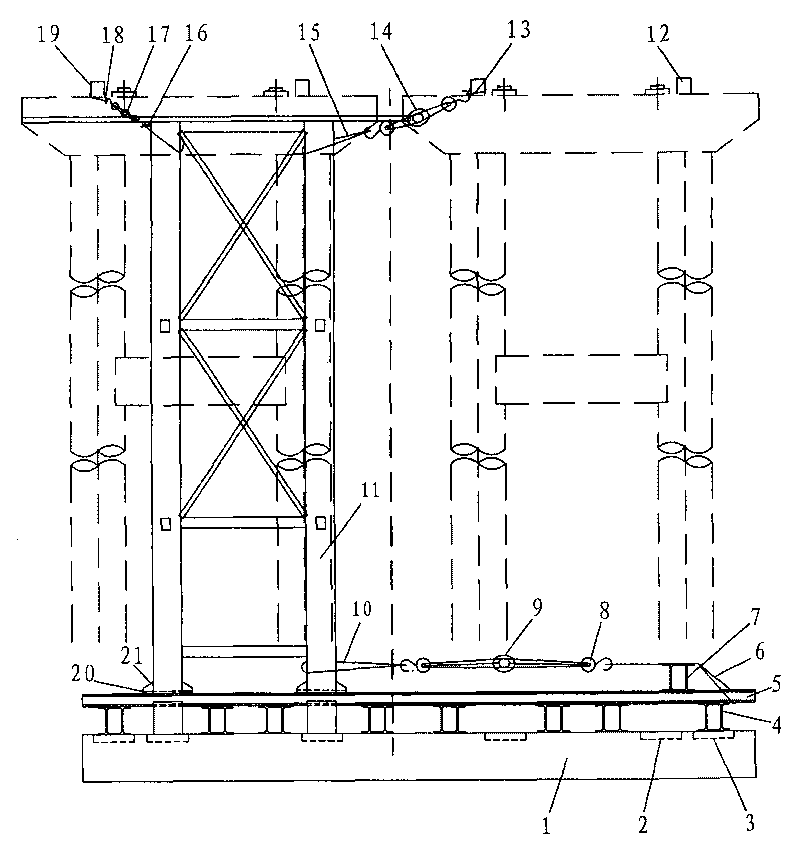

[0038] The overall sliding device for the ground steel pipe column support in the construction of bridge side-span closure section provided by the present invention has a structure as follows: figure 1 and figure 2 Shown: comprise expanding foundation 1, two sliding rails 5, sliding steel plate 20, stand and traction mechanism. Two sliding rails 5 are symmetrically arranged on the enlarged foundation 1, and a sliding steel plate 20 is arranged on each sliding rail, and the sliding steel plate can move on the sliding rail connected to it under the action of the traction mechanism The bottom of each sliding track is supported on the enlarged foundation 1 by a plurality of track leveling supports 4, and these supports have a leveling effect, so that the entire sliding track is horizontally arranged on the enlarged basis 1.

[0039] The stand is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com