Construction process for constructing prilling tower spraying layer by slide mold device dragging construction platform

A technology of construction platform and construction technology, which is applied in the direction of tower, building structure, and construction material processing, etc., can solve the problems such as the difficulty of spraying layer construction in the air, and achieve the effects of saving turnover materials, ensuring safety, and simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings:

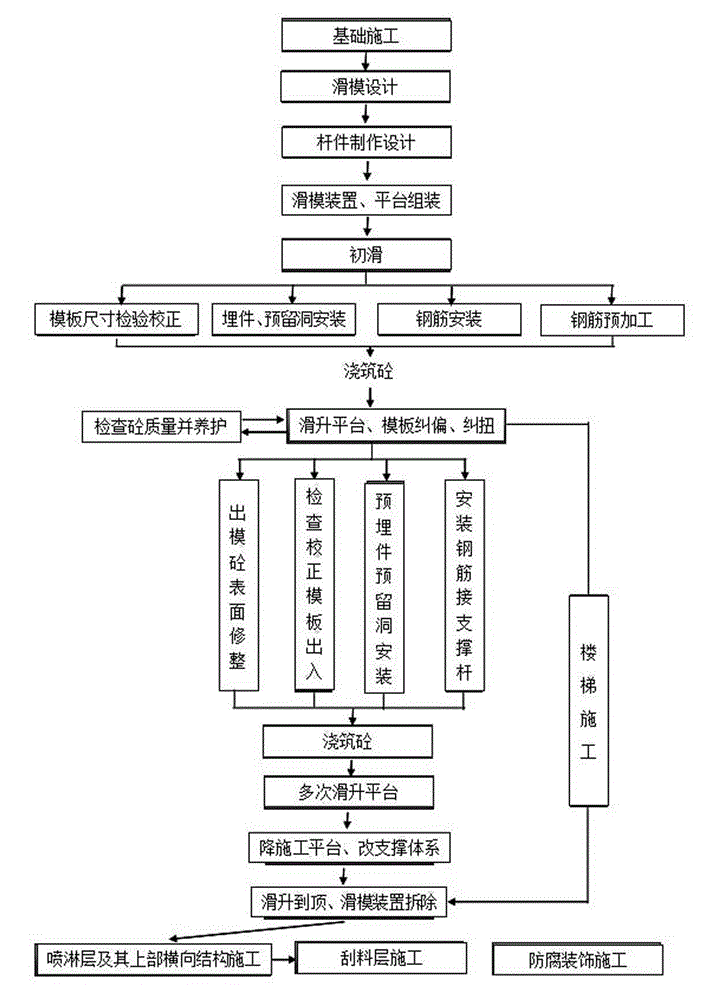

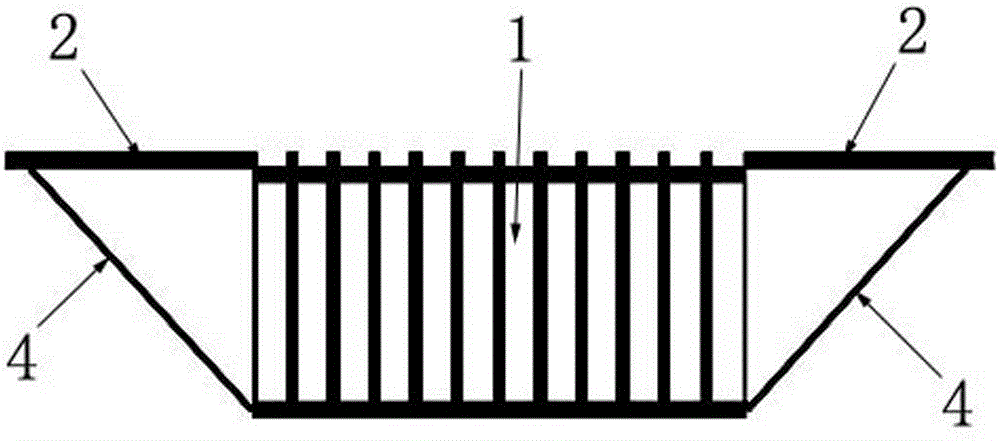

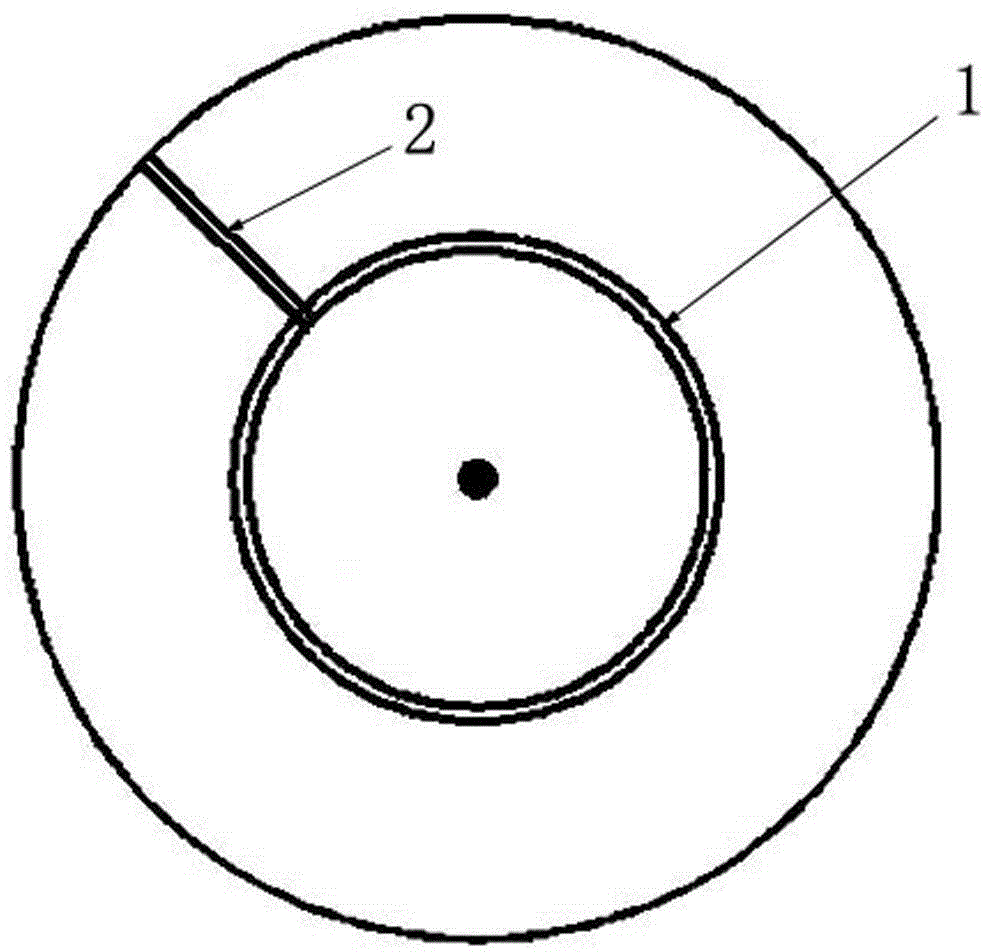

[0020] A construction technique of dragging a construction platform with a sliding-form device to construct a spray layer of a granulation tower. The sliding-form device is used to conduct sliding-form construction on the wall of the granulation tower. During the sliding-form construction, the sliding-form device is used to carry the construction platform to slide up synchronously. When the slip-form construction slides to the position 1-1.5m below the spray layer, several holes are evenly reserved around the wall of the granulation tower for fixing the construction platform; then the slip-form device carries the construction platform to continue the upward slip-form construction , when the slip form construction slides to the position 1-1.5m above the spray layer, the slip form construction is suspended, the construction platform is disconnected from the slip form devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com