Simulated stone dry powder coating and construction method thereof

A dry powder coating and imitation stone technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of increased transportation costs and energy consumption, the inability to achieve the effect of stone texture, and increased construction difficulty, etc., to improve batch scraping Performance, improvement of flexibility and workability, and improvement of color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

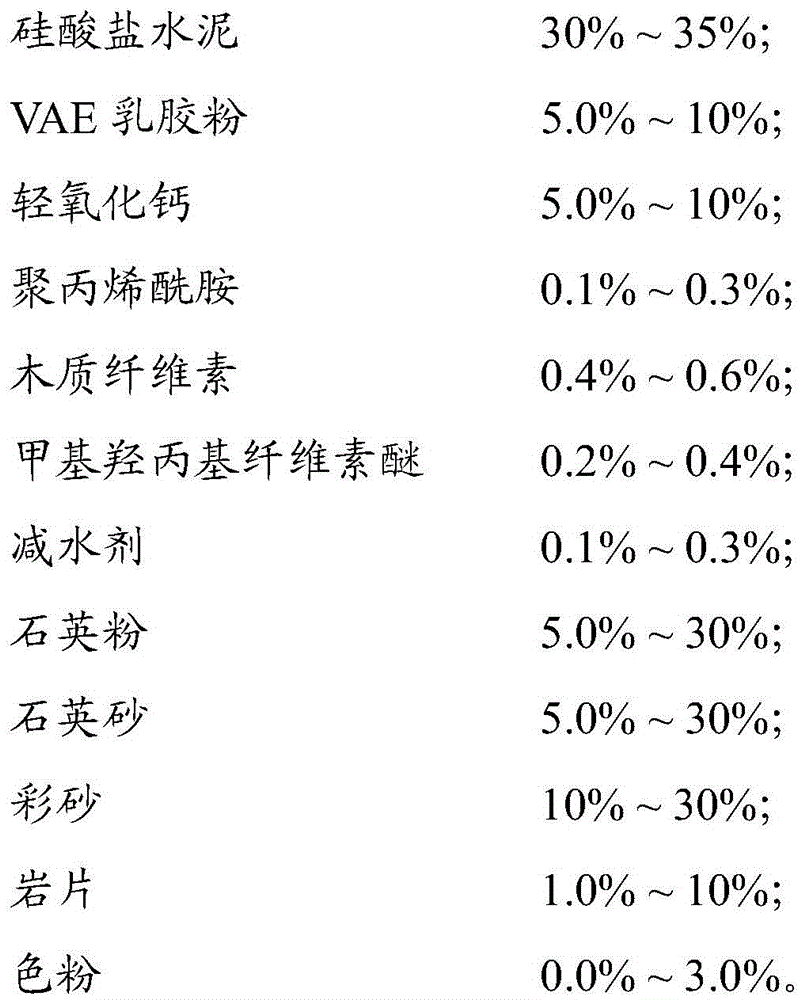

[0027] Embodiment one: prepare imitation stone material dry powder coating of the present invention

[0028] Weigh each component according to the formula in Table 1, stir and mix each component evenly to obtain the imitation stone dry powder coating of the present invention.

[0029] Table 1

[0030] Element

Embodiment 2

[0031] Embodiment two: the construction of imitation stone material dry powder coating of the present invention

[0032] Take the imitation stone dry powder coating prepared in Example 1, add water and stir to mix evenly, and the weight ratio of coating to water mixing is 100:30.

[0033] Use batch scraping method to evenly coat the paint on the building wall to form a coating film. After 35 minutes, the coating film is dry and wet the surface of the coating film with water.

[0034] Use a brush to wipe the surface of the coating film to loosen the fine powder on the surface of the coating film from the coating film, and then immediately pour water on the surface of the coating film to completely detach the loose fine powder from the coating film, showing the Colored sand and rock flakes form a coating film with a stone-like effect.

Embodiment 3

[0035] Embodiment three: performance test of imitation stone material dry powder coating of the present invention

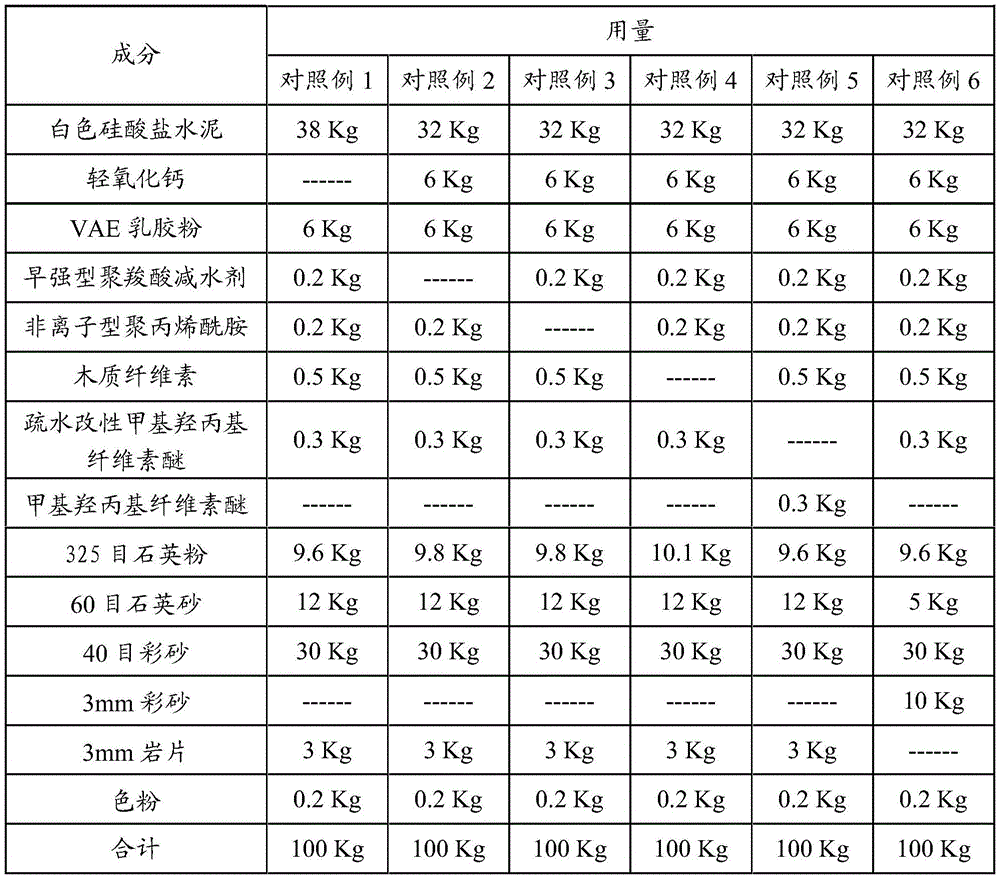

[0036] Each component was weighed according to the formula in Table 2, and each component was stirred and mixed evenly to obtain the imitation stone dry powder coating of each comparative example.

[0037] Table 2

[0038]

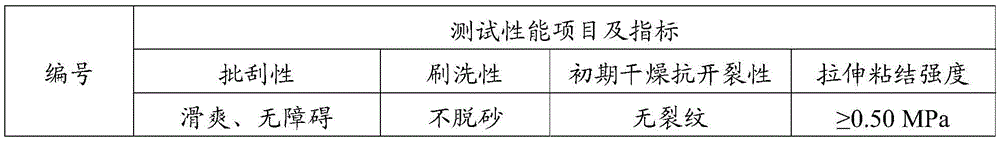

[0039] Performance tests were performed on the imitation stone dry powder coatings prepared in Example 1 and Comparative Examples 1-6, and the test results are shown in Table 3.

[0040] table 3

[0041]

[0042]

[0043] From the above test results, it can be seen that the imitation stone dry powder coating of the present invention has good scratch resistance, scrub resistance and crack resistance, and high tensile bond strength.

[0044]From the comparison of the results of Example 1 and Comparative Example 1, it can be seen that the addition of food-grade calcium hydroxide can improve the scrubbing resistance of the dry powder c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com