Dam face system of hydraulic moving dam

A technology for movable dams and dam surfaces, which is applied in water conservancy projects, sea area projects, coastline protection, etc. It can solve the problems of high maintenance costs, increased costs, and high maintenance costs, so as to improve the service life and use effect, and increase the carrying capacity , the effect of improving the stress situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

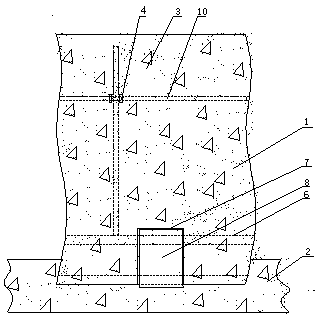

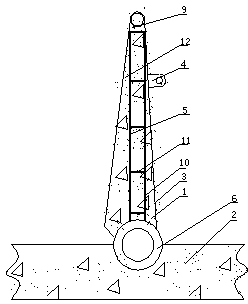

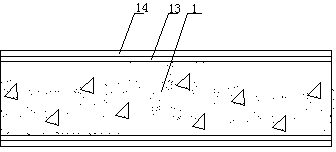

[0019] figure 1 and figure 2 The hydraulic movable dam surface system includes dam surface 1, horizontal foundation 2, dam surface back surface 3, earring structure 4, steel bar grid 5, seamless steel pipe 6, gap 7, rotating sleeve coaxial 8, steel pipe 9, Cross hidden beams 10, connecting ribs 11, dam surface facing water 12, environmental protection polymer chemical coating 13, text layer or pattern layer 14.

[0020] The hydraulic movable dam surface system of the present invention is mainly composed of several steel concrete structure dam surfaces 1 spliced along a straight line, and is cast around the seamless steel pipe 6 arranged at the bottom of the dam surface 1 along the extending direction of the dam surface, and is directly fixed around the dam surface. The rotating sleeve on the horizontal foundation 2 rotates coaxially 8, thereby realizing the relative rotation between the dam surface 1 and the horizontal foundation 2. In order to ensure the connection stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com