Tunnel side wall chiseling sweeper

A technology of tunnel side wall and sweeper, which is applied in tunnels, tunnel linings, wellbore linings, etc., can solve the problems of high labor intensity, ineffective cleaning of accumulated water, strong vibration and impact force, etc., and achieves a high degree of mechanization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

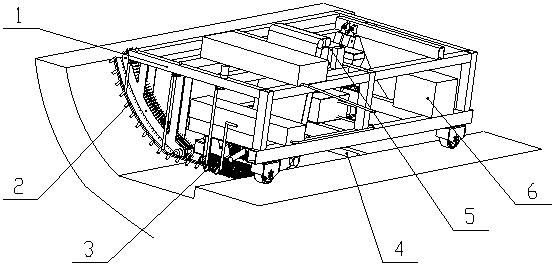

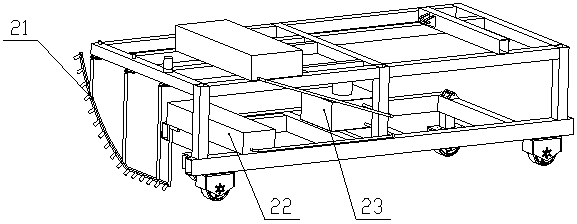

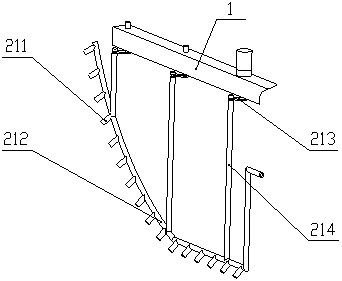

[0047] The following will combine Figure 1-Figure 12 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0048] The tunnel side wall chisel cleaning machine of this embodiment comprises a vehicle frame 1, a chisel system 2, a cleaning system 3, a water removal system 4, a hopper 5, a power and control system 6, and the chisel system includes a nozzle device 21 and a high-pressure water pump. 22. The water storage device 23 is used to generate high-pressure water to roughen the concrete. The cleaning system 3 is used to collect and clean the debris and send the debris to the hopper 5. The water removal system 4 is used to collect and clean the sewage and remove the sewage. Send to the hopper 5, the hopper 5 is used to store sundries and filter sewage and send the filtered water to the water storage device 23, the power and contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com