Method for treating soft foundation

A treatment method and soft foundation technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as difficulty reduction, achieve quality improvement, cost saving, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Construction is being carried out in a seaside development zone, where the geological conditions are: the freshly blown silt is 4-8m thick, forming a land area, with a water content of 80-90%, and a permeability coefficient of 5×10 -8 cm / s, after vacuum preloading, the water content drops to 38-40%, and the bearing capacity is only 55kPa after testing. Since this area needs to build municipal roads in a large area, the above geological conditions cannot meet the design requirements.

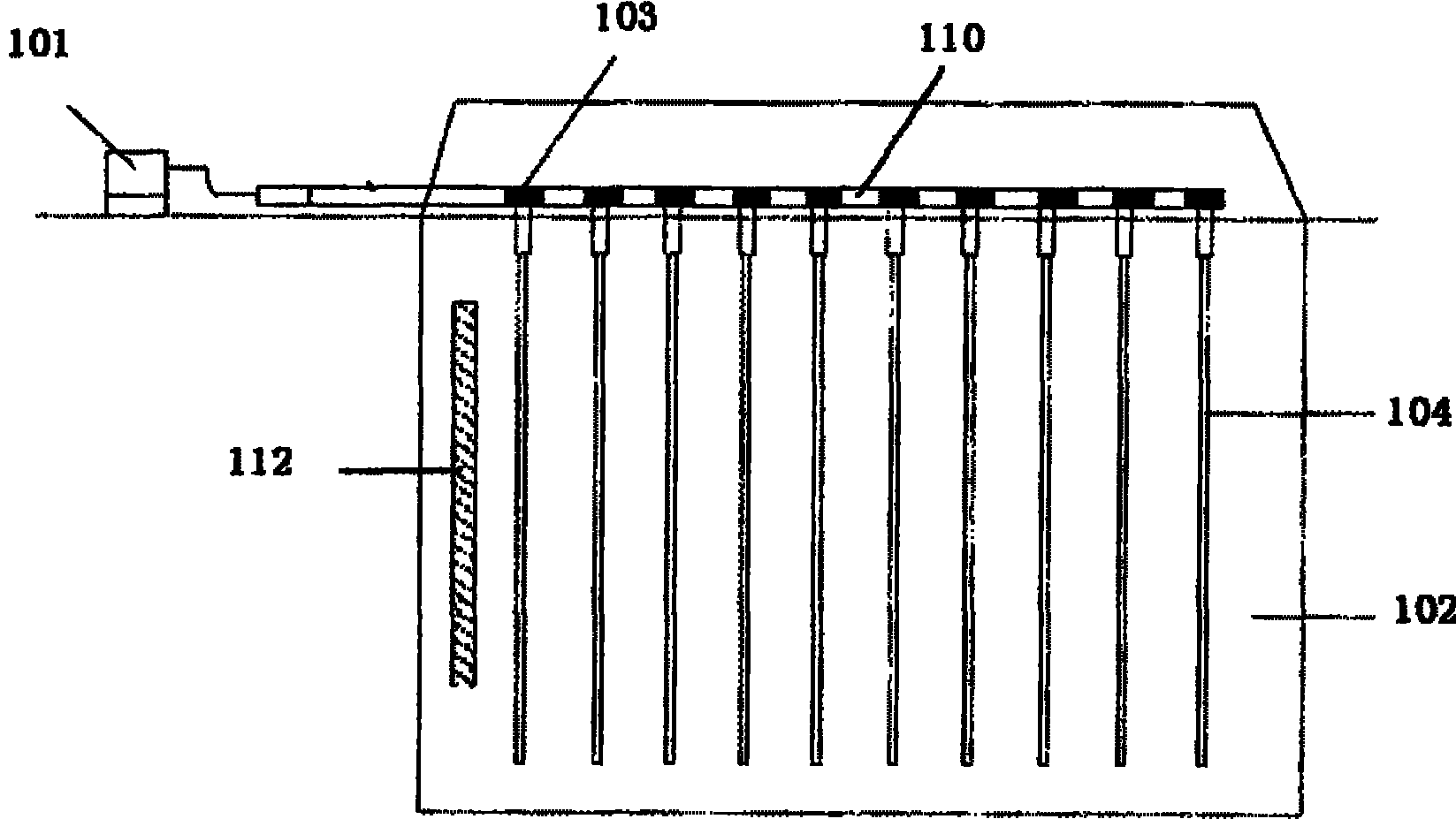

[0040] The specific steps of the processing method of the present embodiment are as follows (the schematic diagram is shown in figure 1 ):

[0041] Step 1, insert electric heating rods 112 with a diameter of φ2cm into the soft soil of the municipal road, arrange them in a square, with a spacing of 0.3m, and an insertion depth of 6m, connect each 1000 electric heating rods as a group, and then connect the main power supply;

[0042] Step 2, insert plastic drainage board 104 on the soft soi...

Embodiment 2

[0046] A certain reservoir was put into a sewage pool (depth 4m) after dredging, with a water content of 98% and a permeability coefficient of 2×10 -8 cm / s; Due to the environmental protection requirements of road traffic anti-drip and the improved silt is directly used as an available dry soil source, the water content of the silt improvement is required to be less than 30%.

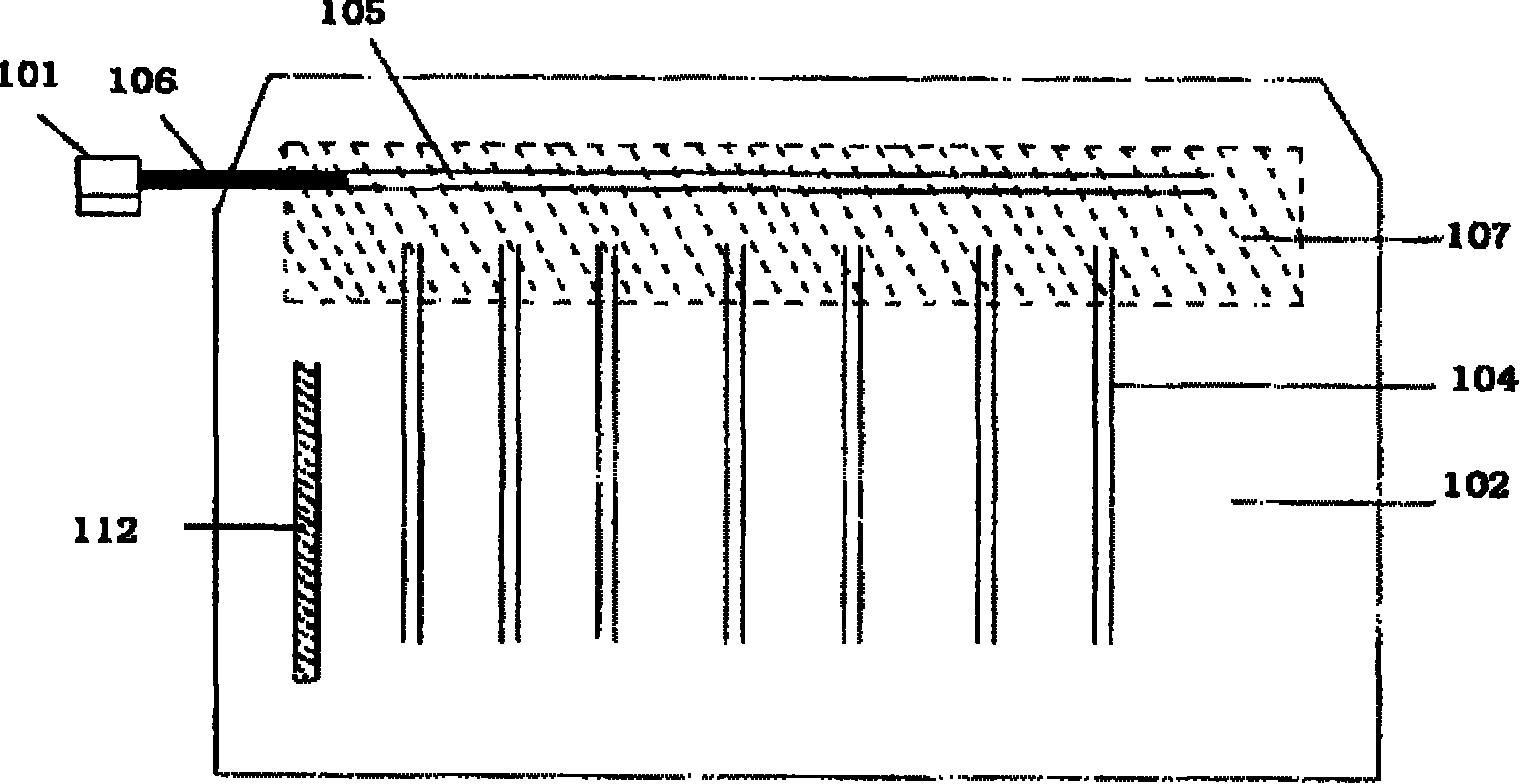

[0047] The specific steps of the processing method of the present embodiment are as follows (the schematic diagram is shown in figure 2 ):

[0048] Step 1, manually laying a layer of geotextile, manually laying a sand cushion 107 with a thickness of 0.5m, and burying a horizontal ventilation hose 105 every 6m in the sand cushion;

[0049]Step 2, insert the electric heating rods 112 with a distance of 1.5m and a depth of 3.5m, each group of 800 rods is arranged in a triangle, and the electric heating rods are connected to each other, and then connected to the main power transformer;

[0050] Step 3, i...

Embodiment 3

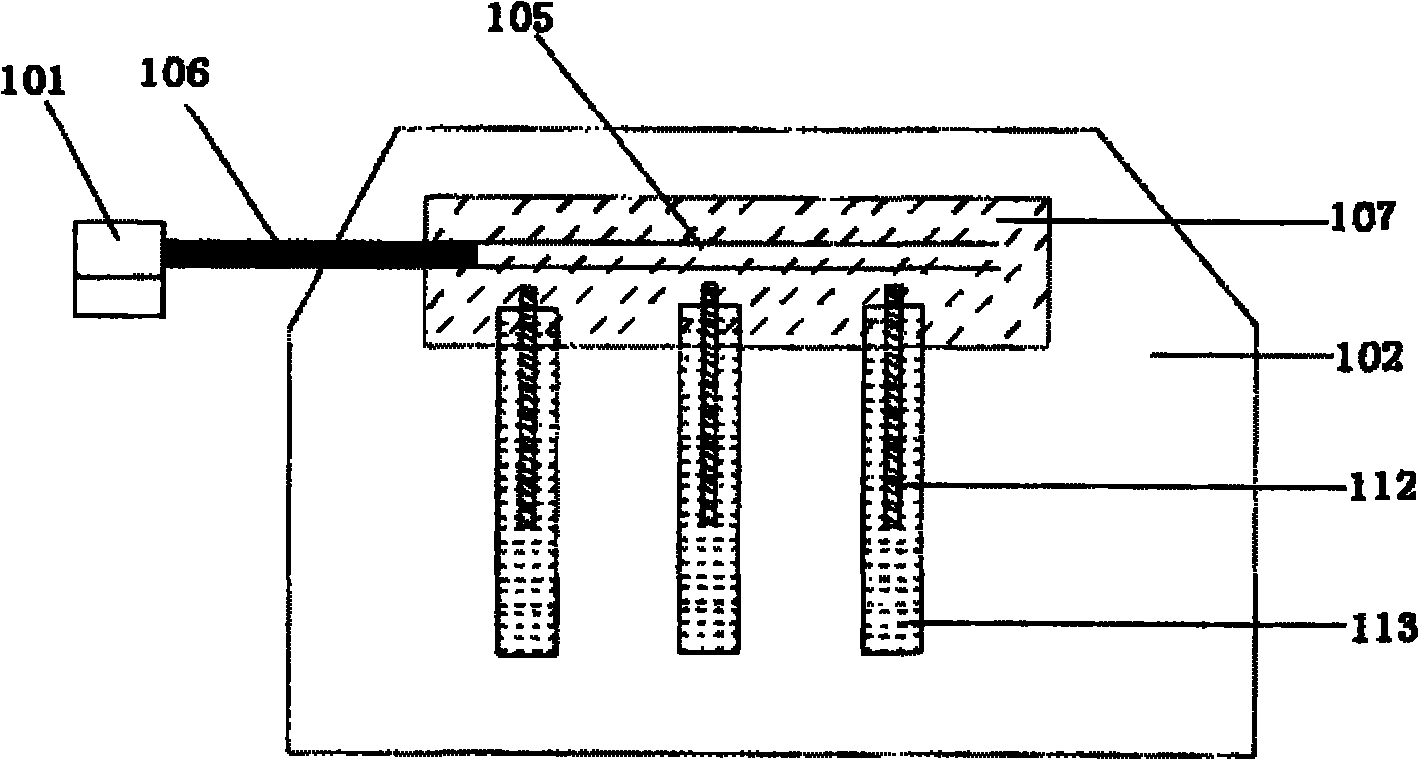

[0055] With the soft soil construction conditions in embodiment 2, the present embodiment adopts different methods to process, and concrete steps are as follows (see the schematic diagram image 3 ):

[0056] Step 1, preparing a sand well 113, the sand well is a drainage column formed by drilling holes in the foundation and pouring medium and coarse sand in order to accelerate the drainage and consolidation of weak foundations, or pouring sand into woven bags into the holes Insert electric heating rods 112 into the sand wells 113, insert one electric heating rod 112 into each sand well 113, connect the electric heating rods 112 to each other, and then connect them to the main power transformer; the sand wells 113 are arranged in a triangle, Spacing 0.3-5 meters, depth 3.5m;

[0057] Step 2: First lay a layer of geotextile on the sand well 113, manually lay a 0.5m thick sand cushion layer 107, and embed horizontal ventilating hoses 105 every 6m in the sand cushion layer; the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com