Reagent for separating sludge and water from bored pile waste sludge

A technology for drilling cast-in-place piles and waste mud, which is applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc. Separation effect, short processing time, simple processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

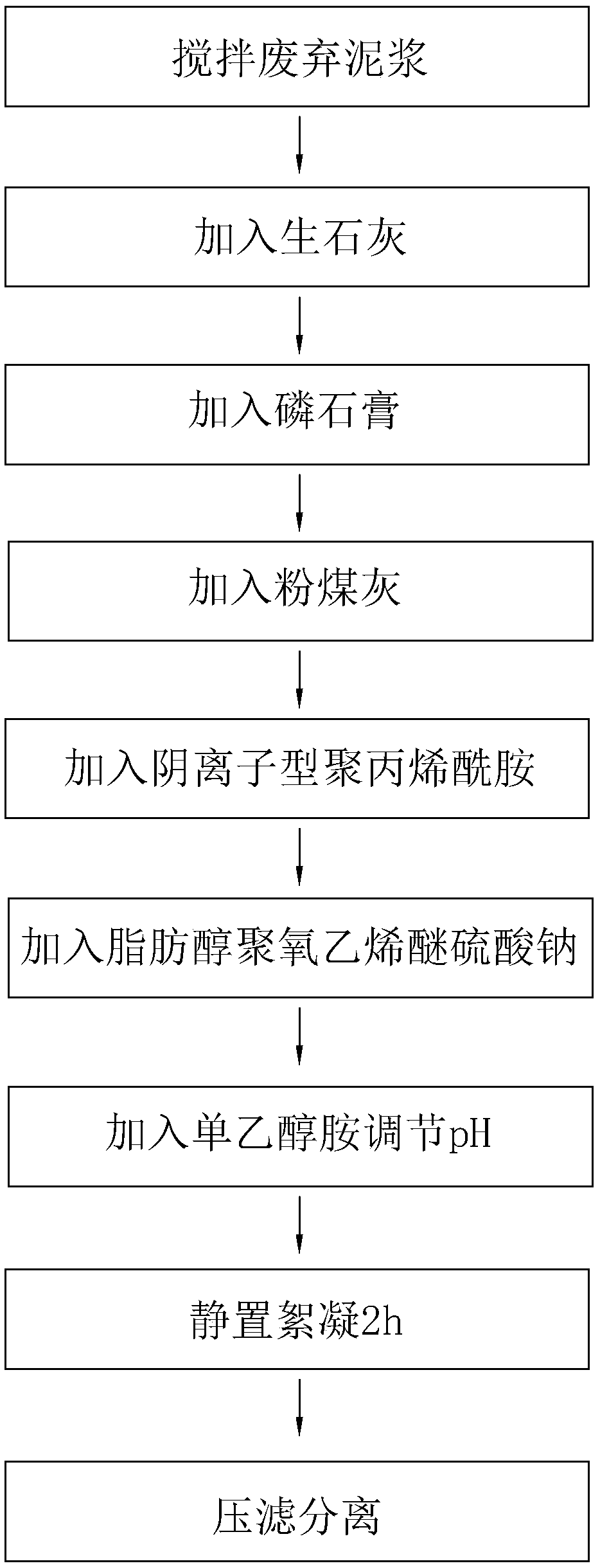

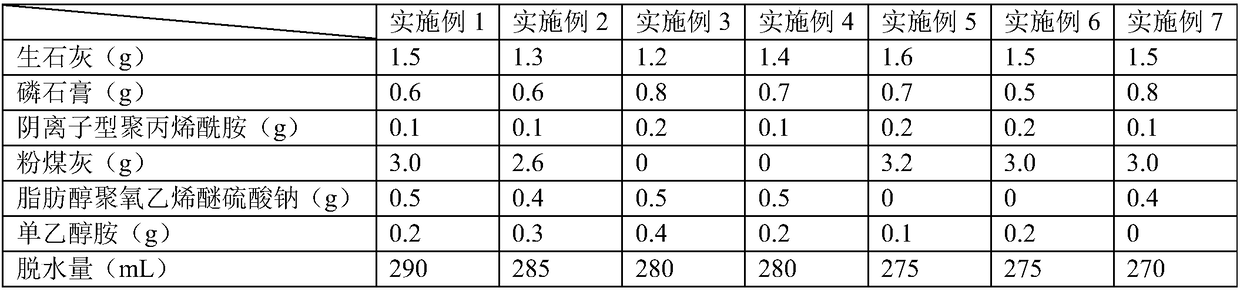

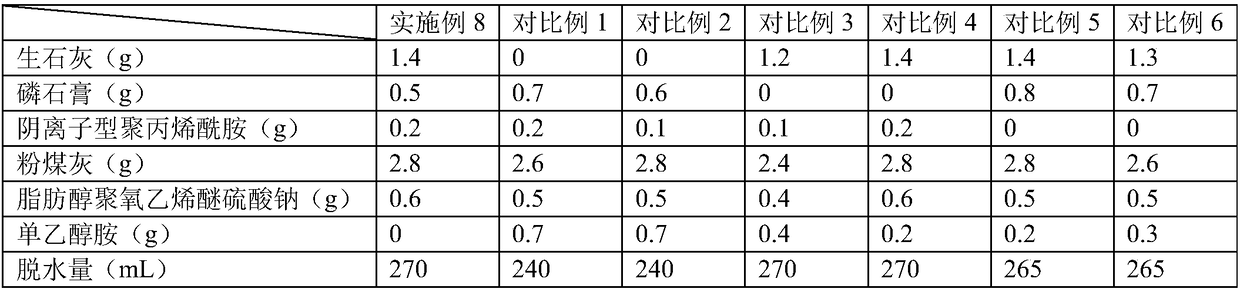

[0040] Embodiment 1, a kind of bored cast-in-situ pile waste mud mud-water separation method, in every 500mL mud, by weight, the separation reagent raw material component that adopts is as shown in table 1, and this method comprises the following steps (referring to figure 1 ):

[0041] Step 1. Stir the waste mud evenly, and add quicklime, phosphogypsum, fly ash, anionic polyacrylamide, and fatty alcohol polyoxyethylene ether sodium sulfate in sequence, and mix each component evenly before proceeding to subsequent grouping. The addition of points, the addition is completed and stirred evenly to obtain a mixture;

[0042] Step 2, adding monoethanolamine to the mixture, adjusting the pH to 8-10 and stirring evenly;

[0043] Step 3, after stirring evenly, let stand for 2 hours for flocculation, perform pressure filtration and complete mud-water separation.

Embodiment 2

[0044] The difference between Example 2 and Example 1 is that, in parts by weight, the raw material components of the separation reagent are shown in Table 1.

Embodiment 3

[0045] Embodiment 3, a method for separating mud and water from waste mud of cast-in-place bored piles. In every 500mL of mud, by weight, the raw material components of the separation reagent used are shown in Table 1. The method includes the following steps:

[0046] Step 1. Stir the waste mud evenly, and add quicklime, phosphogypsum, anionic polyacrylamide and fatty alcohol polyoxyethylene ether sodium sulfate in sequence, and then add the subsequent components after stirring each component evenly. The addition is completed and stirred evenly to obtain a mixture;

[0047] Step 2, adding monoethanolamine to the mixture, adjusting the pH to 8-10 and stirring evenly;

[0048] Step 3, after stirring evenly, let stand for 2 hours for flocculation, perform pressure filtration and complete mud-water separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com