A biological polysaccharide-based heavy metal scavenger and preparation method thereof

A technology of heavy metal capture agent and biological polysaccharide, which is applied to chemical instruments and methods, water pollutants, natural water treatment, etc., can solve the problems of single type of heavy metal chelating functional groups, poor heavy metal capture performance, and cumbersome preparation process, etc., to achieve Strong affinity, less added amount, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

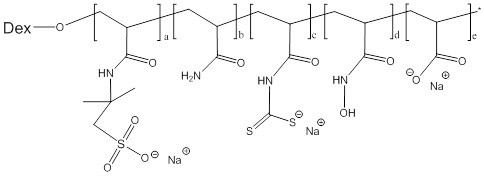

[0029] A preparation method of a biological polysaccharide-based heavy metal scavenger, characterized in that the preparation method of the metal scavenger is as follows:

[0030]1) Graft copolymerization of biopolysaccharides: heat the biopolysaccharide solution to 20-30°C with sufficient nitrogen gas, add an initiator at a dosage of 1-3wt‰ (accounting for the solid mass ratio of the total reactants), and control the stirring speed at 100-150r / min, after 10-15min, slowly add the mixed solution of 2-acrylamide-2-methylpropanesulfonate sodium and acrylamide, increase the speed to 200-250r / min, stir for 10-15min and heat up to 40°C Afterwards, stop stirring and keep warm for 4-6 hours to obtain a biopolysaccharide graft copolymer containing sulfonic acid groups and amide groups; 2) Xanthation reaction: adjust the pH of the product in 1) to 8-12, and lower the temperature of the system to Control the temperature at 25-40°C, then slowly add carbon disulfide dropwise, the mass rati...

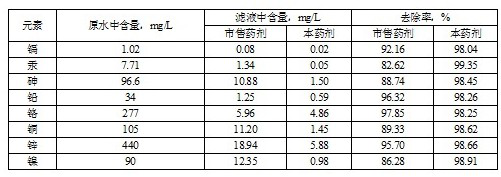

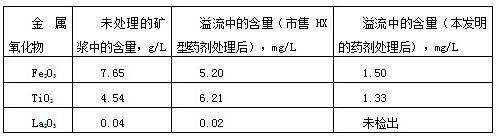

Embodiment 1

[0033] Graft copolymerization reaction of biological polysaccharides: weigh biological polysaccharides to prepare 200g of 15% aqueous solution, and prepare 40% sodium 2-acrylamide-2-methylpropanesulfonate and acrylamide (the mass ratio of the two is 1:5) 100g of the mixed solution was set aside, then poured the biopolysaccharide solution into a three-necked flask, started stirring and raised the temperature to 30°C, and after the nitrogen was fully ventilated to remove oxygen, 0.07g of potassium persulfate was added, the stirring speed was adjusted to 150r / min, and after stirring for 10min Add 0.02g sodium sulfite, continue to stir for 10min, start to slowly add the mixed solution of 2-acrylamide-2-methylpropanesulfonate sodium and acrylamide, and adjust the speed to 200r / min, stir for 15min, then raise the temperature to 40°C, stop Stir, stop nitrogen, keep warm for 4h.

[0034] Xanthogenation reaction: Cool the above product to room temperature, adjust the pH to 10.0, then r...

Embodiment 2

[0042] Graft copolymerization reaction of biopolysaccharide: weigh biopolysaccharide to make 15% aqueous solution 200g, and prepare 7.5% sodium 2-acrylamide-2-methylpropanesulfonate and acrylamide (the mass ratio of the two is 1:1) 400g of the mixed solution was set aside, then poured the biopolysaccharide solution into a three-necked flask, started stirring and raised the temperature to 20°C, after sufficient nitrogen deoxygenation, added 0.15g of potassium persulfate, adjusted the stirring speed to 150r / min, and stirred for 10min Add 0.03g sodium bisulfite, continue to stir for 10min, start to slowly add the mixed solution of 2-acrylamide-2-methylpropanesulfonate sodium and acrylamide, and adjust the speed to 250r / min, stir for 10min and then heat up to 40 ℃, stop stirring, stop nitrogen, and keep warm for 4h.

[0043] Xanthogenation reaction: Cool the above product to room temperature, adjust the pH to 8-9, then raise the temperature to 40°C, start stirring, slowly add 15g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com