Magnesium indium solid solution and preparation method thereof

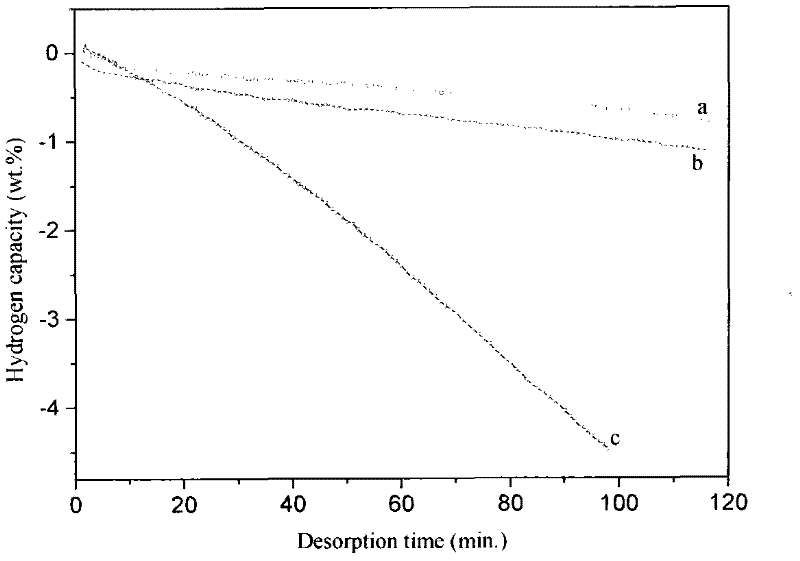

A technology of solid solution and indium powder, which is applied in the field of magnesium indium solid solution and its preparation, can solve the problems of irreversible reversibility, reduce the enthalpy change of hydrogen absorption and desorption of magnesium, and reduce the thermodynamic stability of magnesium hydride, so as to reduce the hydrogen desorption temperature, Fully reversible hydrogen absorption and desorption, excellent hydrogen storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

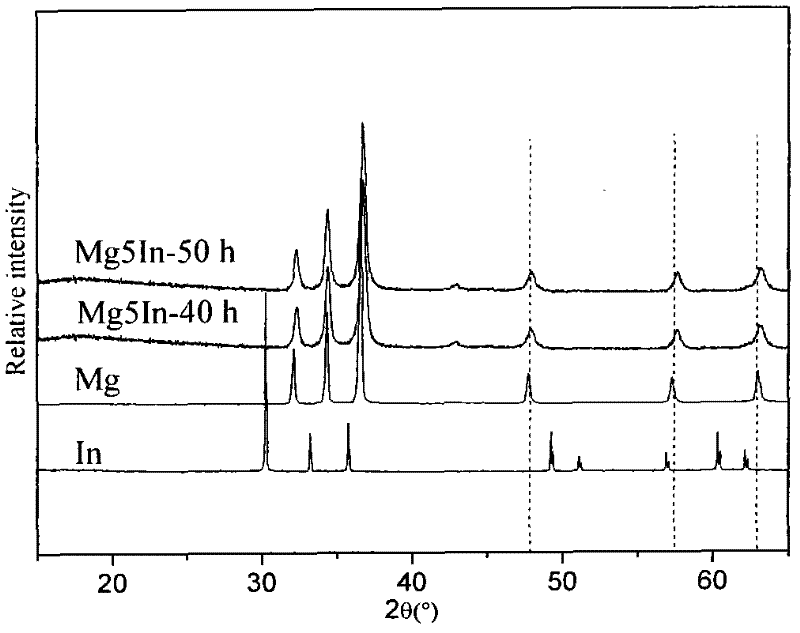

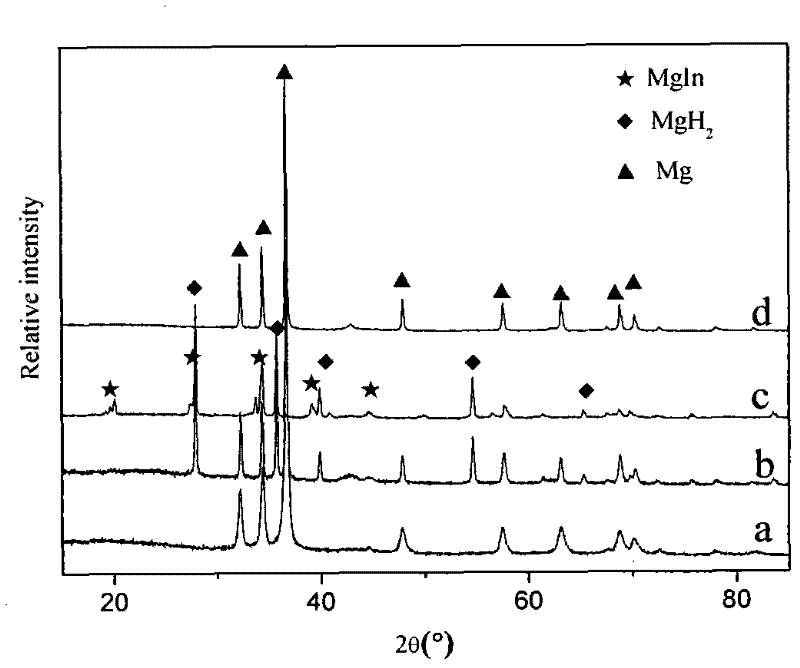

[0029] (1) Mix Mg powder and In powder according to the molar ratio of 95:5 to prepare sample A;

[0030] (2) The sample A prepared according to the ratio of step (1) is ball milled on a planetary ball mill for powder mixing to obtain mixed powder B;

[0031] (3) Compress the mixed powder B obtained in step (2) at 100 MPa to obtain a green body C, and sinter the green body C in a vacuum furnace at 560°C for 3 hours under argon protection, and the protection pressure is 1 atmospheric pressure.

[0032] (4) After the green body C that has been sintered in step (3) is broken, it is ball milled under an argon atmosphere to obtain a magnesium-indium solid solution alloy.

Embodiment 2

[0034] (1) Mix Mg powder and In powder according to the molar ratio of 95:5 to prepare sample A;

[0035] (2) The sample A prepared according to the ratio of step (1) is ball milled on a planetary ball mill for powder mixing to obtain mixed powder B;

[0036] (3) Compress the mixed powder B obtained in step (2) at 100 MPa to obtain a green body C, and sinter the green body C in a vacuum furnace at 400° C. for 3 hours under argon protection, and the protection pressure is 1 atmospheric pressure.

[0037] (4) After the green body C that has been sintered in step (3) is broken, it is ball milled under an argon atmosphere to obtain a magnesium-indium solid solution alloy.

Embodiment 3

[0039] (1) Mix Mg powder and In powder according to the molar ratio of 90:10 to prepare sample A;

[0040] (2) The sample A prepared according to the ratio of step (1) is ball milled on a planetary ball mill for powder mixing to obtain mixed powder B;

[0041] (3) Compress the mixed powder B obtained in step (2) at 100 MPa to obtain a green body C, and sinter the green body C in a vacuum furnace at 560 ° C for 3 hours under argon protection, and the protection pressure is 1 atmospheric pressure.

[0042] (4) After the green body C that has been sintered in step (3) is broken, it is ball milled under an argon atmosphere to obtain a magnesium-indium solid solution alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com