A kind of natural rubber/nanometer silicon dioxide composite material and preparation method thereof

A technology of nano-silica and natural rubber, applied in the field of rubber composite materials, can solve the problems of stress concentration of composite materials, unfavorable processing of composite materials, poor mechanical properties, etc., and achieve the effects of weakening agglomeration, avoiding water pollution problems, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

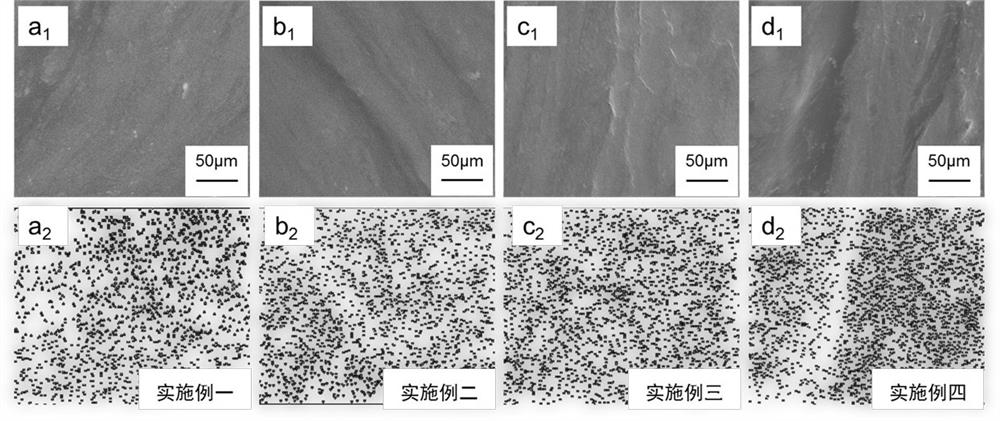

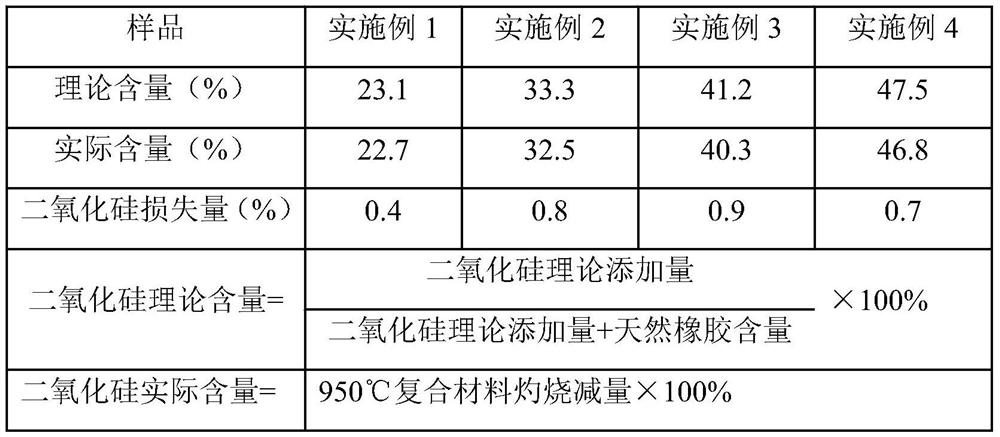

[0042] Based on the dry rubber content of natural rubber emulsion 100phr, take 3.75phr ethanol, 30phr vinyltriethoxysilane modified nano-silica (soak the surface-modified nano-silica with ethanol), and then add it to 116.25phr distilled water , be warming up to 50 ℃, after stirring for 20min, prepare the nano-silica alkanol aqueous solution of 20% solid content; and ammoniated natural rubber latex (25% of dry rubber content) 400g, under the condition of 50 ℃, flow control (can be according to actual situation adjustment) and pumped into the reaction kettle at the same time, stirring at a speed of 200rad / min for 10 minutes to obtain composite micelles (flocs); the flocs were crepe, washed, crushed, and dried to obtain natural rubber / nano-silicon dioxide composite material.

[0043] The content of silicon dioxide in the composite material prepared in this example is shown in Table 1. It can be seen from Table 1 that the loss of nanometer silicon dioxide during the mixing process...

Embodiment 2

[0046] Based on 100phr of dry rubber content of natural rubber emulsion, get 6.25phr propanol, 50phr γ-(2,3-epoxypropoxy) propyltrimethoxysilane modified nano-silica (impregnated with propanol through surface modification) Nano silicon dioxide), then join in 193.75phr distilled water, be warming up to 60 ℃, after stirring for 20min, prepare the nano silicon dioxide alkanol aqueous solution of 20% solid content; 400g, under the condition of 70°C, control the flow rate and pump into the reaction kettle at the same time, stir at the speed of 200rad / min for 8min, and then the composite micelles (flocs) can be obtained; and dry to obtain the natural rubber / nano silicon dioxide composite material.

[0047] The silica content in the composite material prepared in this example is shown in Table 1. The above-mentioned natural rubber / nano-silica composite material 150phr, Si695phr, zinc oxide 5phr, stearic acid 1.5phr, accelerator CBS 1.5phr, accelerator D0.5phr, sulfur 1.5phr, mixing,...

Embodiment 3

[0049] Based on the dry rubber content of natural rubber emulsion 100phr, get 8.75phr propylene glycol, 70phr dimethyldiethoxysilane modified nano-silica (infiltrate the surface-modified nano-silica with propylene glycol), then add to 271.25phr distilled water In the process, heat up to 70°C, stir for 20 minutes, prepare a 20% solid content nano-silica alkanol aqueous solution; and 400g of ammoniated natural rubber latex (dry rubber content 25%), at 50°C, control the flow rate and pump it into the reaction at the same time kettle, stirring at a speed of 200 rad / min for 15 minutes to obtain composite micelles (flocs); crepe, wash, crush, and dry the composite micelles (floes) to obtain natural rubber / nanometer silica composite Material.

[0050] The silica content in the composite material prepared in this example is shown in Table 1.

[0051] The above-mentioned natural rubber / nano-silica composite material 170phr, Si695phr, zinc oxide 5phr, stearic acid 1.5phr, accelerator C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com