A kind of polymer emulsion that can be flocculated by CO2 gas and its preparation and flocculation method

A technology for copolymerizing emulsions and emulsions, which is applied in the fields of materials and fine chemicals to achieve the effects of low environmental pollution, low energy consumption, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention proposes a method for preparing a polymer emulsion with a core-shell structure, characterized in that the preparation method comprises the following two steps:

[0034] (a) Preparation of seed emulsion: The free radical polymerizable monomer is carried out emulsion copolymerization in the presence of anionic emulsifier or composite emulsifier, crosslinking agent, initiator, deionized water and auxiliary agent to obtain polymer Seed lotion.

[0035] The amount of free radical polymerizable monomers used to prepare the seed emulsion accounts for 95-5wt% of the total amount of free radical polymerized monomers used to prepare the core-shell structure polymer emulsion; 0-10wt% of the monomer consumption of radical polymerization, preferably 0.05-5%; the initiator consumption is 0.05-5wt% of the monomer consumption that can carry out radical polymerization of the preparation seed emulsion, preferably 0.2-2wt%; emulsifier consumption 0-5wt%, preferably ...

Embodiment 1

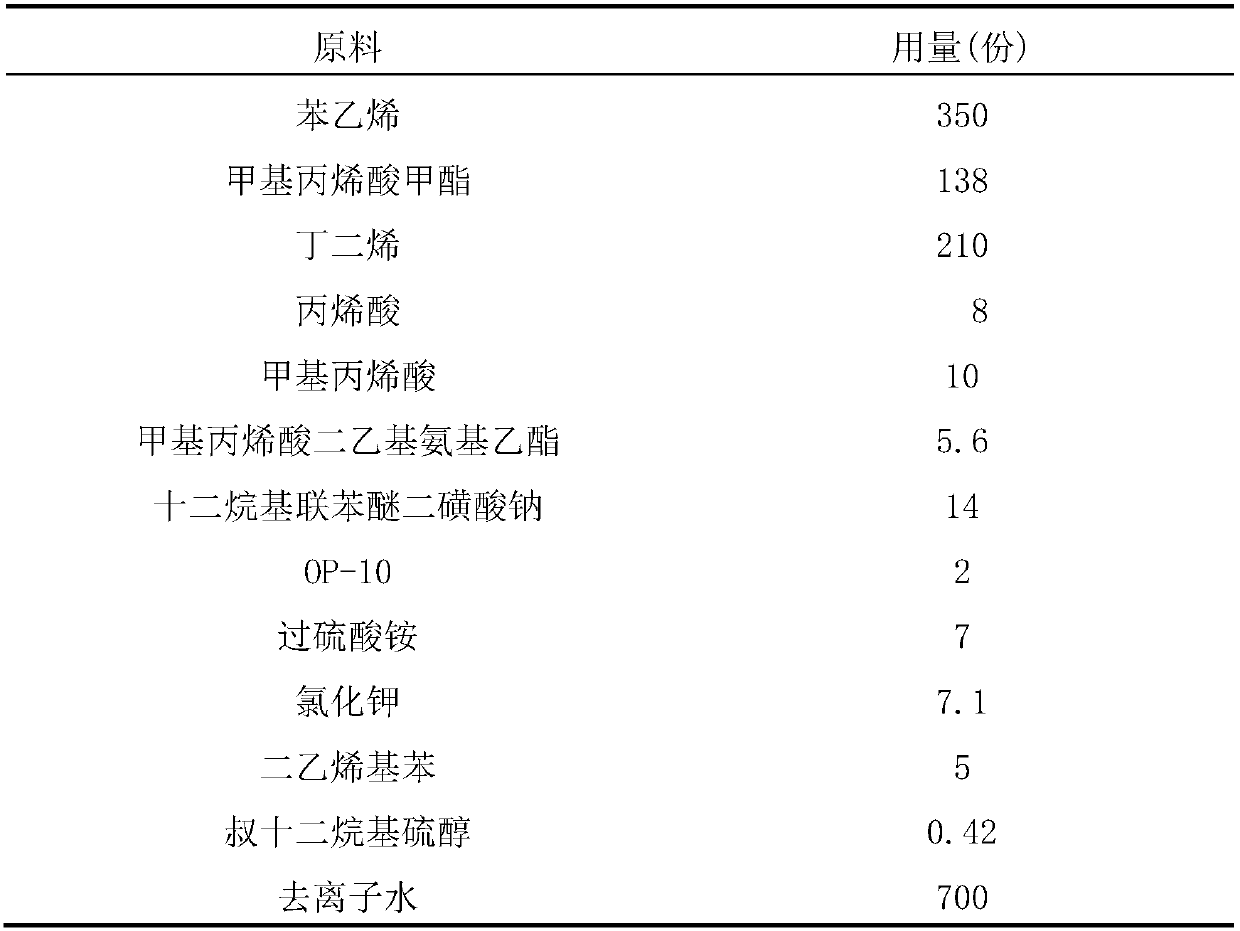

[0043] Embodiment 1—poly(methyl methacrylate-butadiene-styrene) emulsion system—preparation of MBS resin

[0044] The following table is the synthetic formula of polymer emulsion:

[0045]

[0046] According to the formula in the table, weigh 320 parts of styrene, 8 parts of acrylic acid, 10 parts of methacrylic acid, 12 parts of sodium dodecyl diphenyl ether disulfonate, 5 parts of ammonium persulfate, 0.42 parts of tert-dodecyl Mercaptan, 600 parts of water, 5 parts of divinylbenzene and 7.1 parts of potassium chloride were put into the autoclave, and nitrogen gas was passed for 10 minutes, and then 210 parts of butadiene were introduced into the autoclave from the cylinder. First, pre-emulsify the raw material system in the kettle at 25°C for 1 hour, then raise the temperature to 50°C, react for 7 hours, then raise the temperature to 63°C, and react for another 2 hours. The measured solid content reaches more than 45%, and the monomer conversion rate is 95%. More than %...

Embodiment 2

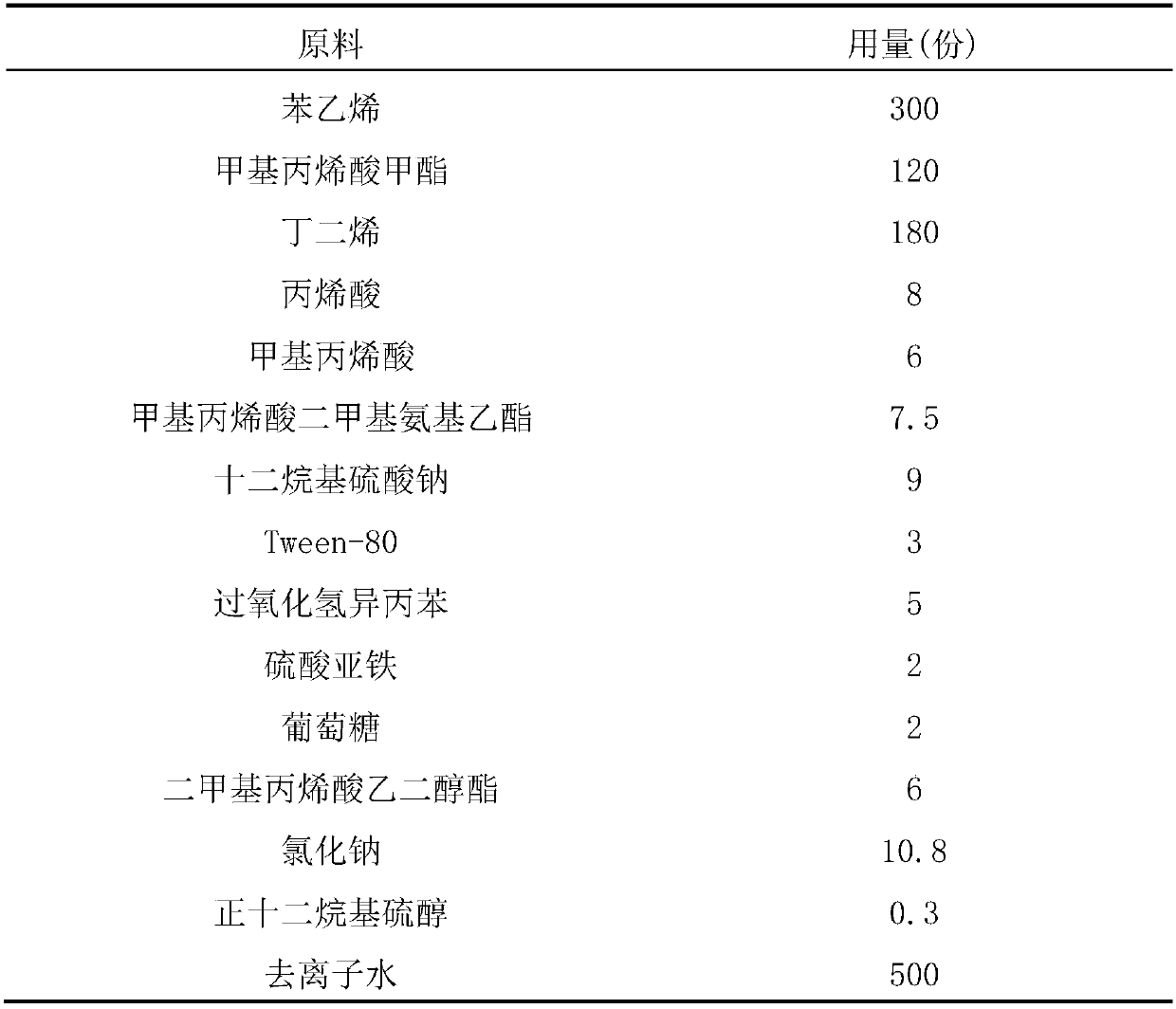

[0049] Embodiment 2—poly(methyl methacrylate-butadiene-styrene) emulsion system—preparation of MBS resin

[0050] The following table is the synthetic formula of polymer emulsion:

[0051]

[0052] According to the formula in the table, weigh 300 parts of styrene, 8 parts of acrylic acid, 6 parts of methacrylic acid, 7 parts of sodium lauryl sulfate, 3 parts of cumene hydroperoxide, 1 part of ferrous sulfate, and 1 part of glucose 0.3 parts of n-dodecyl mercaptan, 5 parts of ethylene glycol dimethacrylate, 10.1 parts of sodium chloride and 450 parts of water are put into the autoclave, and nitrogen gas is passed for 10 minutes, and then 180 parts of butadiene are discharged from the cylinder into the reactor. First, pre-emulsify the raw material system in the kettle at 35°C for 1.5 hours, then raise the temperature to 60°C, react for 5 hours, then raise the temperature to 75°C, and react for another hour. The measured solid content reaches more than 45%, and the monomer co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com