Building construction system

A technology of building and core tube, which is applied in the direction of building structure, construction, and building material processing, etc. It can solve the problems of inconvenient construction, poor concrete quality, and long construction period, so as to reduce the construction period and improve the smoothness of concrete , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

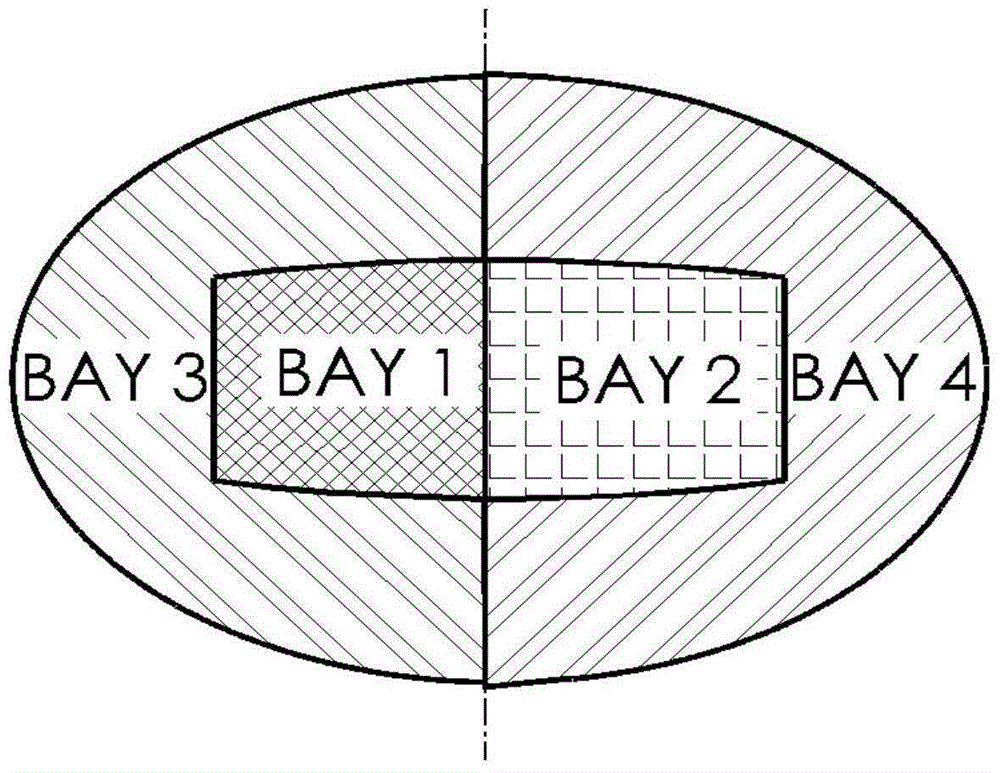

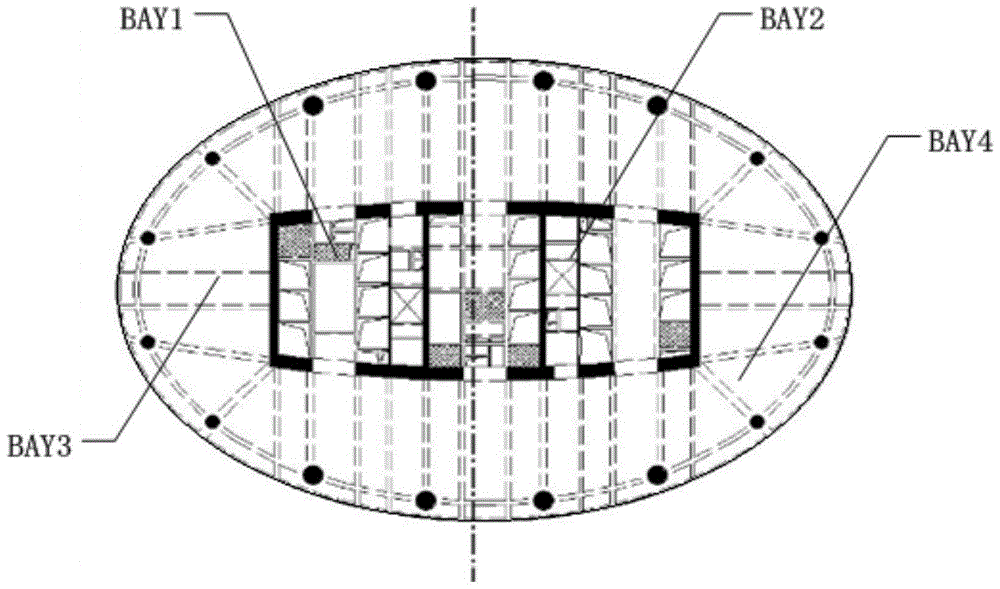

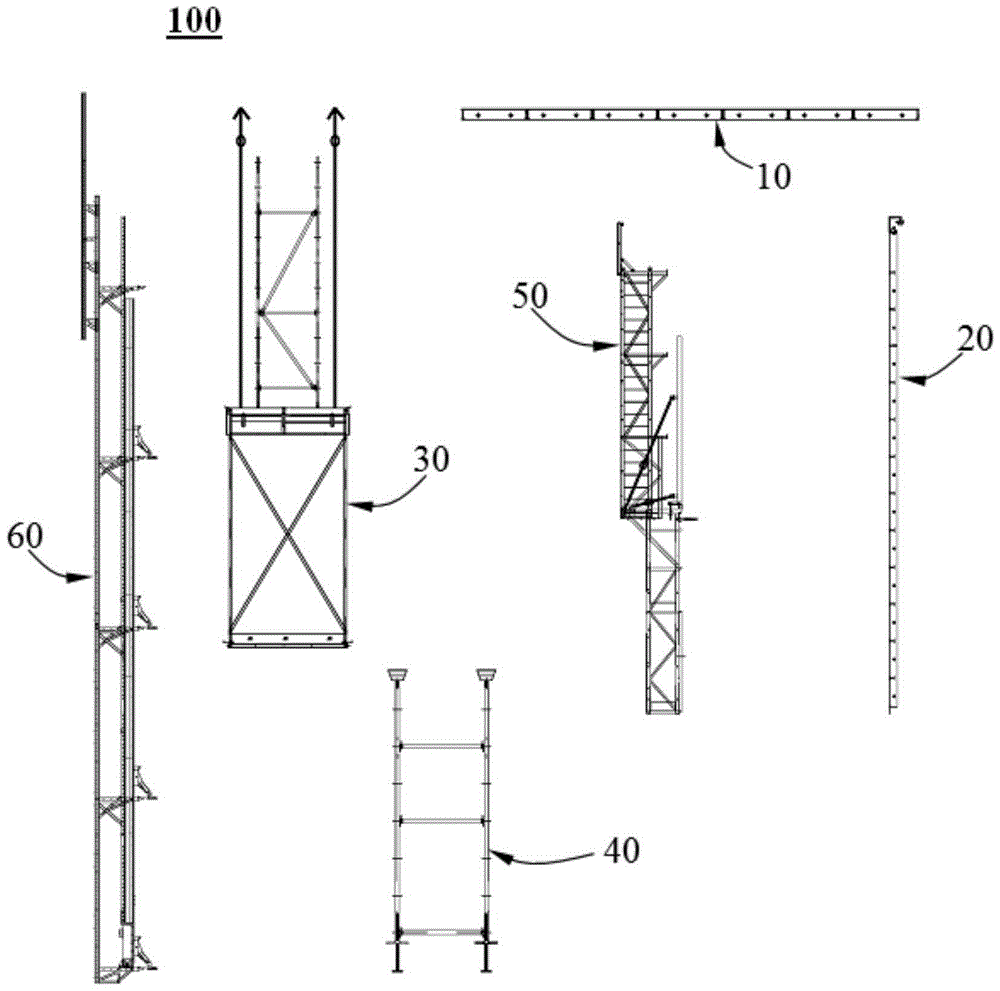

[0031] figure 1 and figure 2 Shown is a schematic diagram divided into sections according to the basic structure of the building, which divides the building into core tubes (i.e. BAY1 and BAY2) and peripherals (BAY3 and BAY4). For this reason, based on this structural feature of the building, the present invention A building construction system 100 that can improve construction convenience and construction quality is provided, which uses a large number of aluminum mold systems and steel mold workbenches, such as image 3 Part of the components shown in , including aluminum formwork 10 for floor slabs and aluminum formwork 20 for wall columns, etc., elevator shaft system 30 (including elevator shaft steel form workbench 31 and elevator shaft aluminum formwork system 32 ), scaffolding support system 40 , core tube exterior wall steel formwork system 50 and peripheral exterior wall protection system 60, these components will be widely used in the core tube and the periphery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com