Construction technology for precisely positioning and quickly installing steel pipe column in covered top-down excavation method

A construction technology and precise positioning technology, which is applied in the direction of basic structure engineering, construction, sheet pile walls, etc., can solve the problems of long construction period of foundation concrete, large steel casings, and high safety risks of operators, and achieve labor costs and Relevant measures cost reduction, risk reduction, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

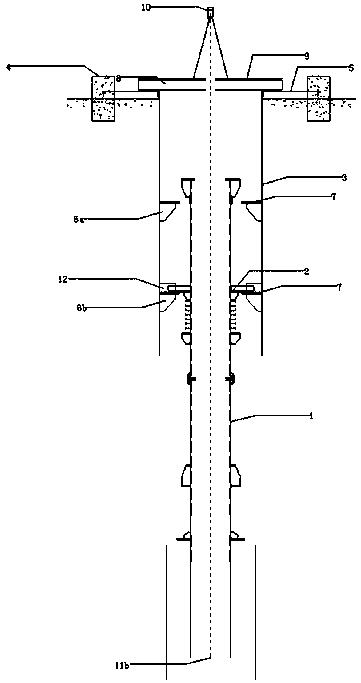

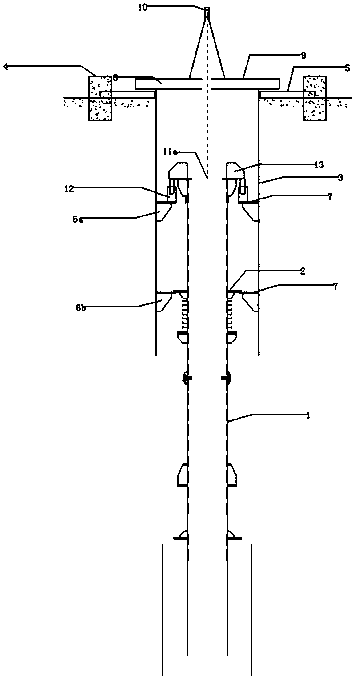

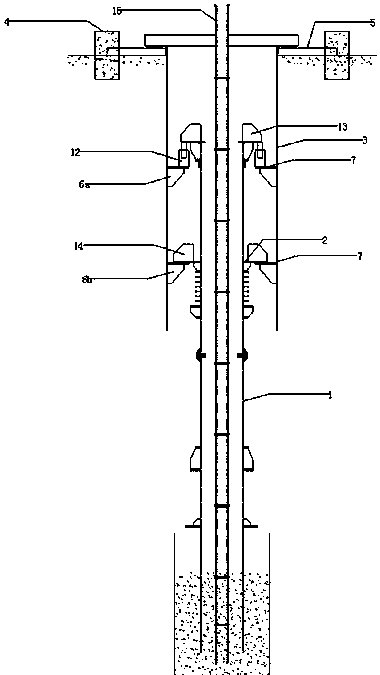

[0025] The precise positioning and rapid installation construction process of the steel pipe column in the cover-excavation method in this embodiment includes the following steps:

[0026] In the first step, after the reinforcement cage of the pile foundation is hoisted, the concrete pier 4 of 1000*500*500mm is poured in the cross direction of the steel casing 3 and the support of the channel steel 5 of 150*1250mm is installed, and the steel casing 3 is reinforced and fixed, and one end of the channel steel 5 The concrete pier 4 is embedded, and the other end is fully welded with the steel casing 3.

[0027] The second step is to measure the elevation and coordinates of the steel casing 3, determine the relative elevation and coordinates of the steel pipe column 1, and weld the first support steel plate 6a at 50 cm below the top elevation of the steel pipe column 1 and the reinforcement ring 2 of the first steel pipe column 1 and the second supporting steel plate 6b, arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com