Copolyamide hot melt adhesive and its preparation method

A technology of copolyamide and hot melt adhesive, which is applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc. High and low temperature performance and mechanical properties, low water absorption, easy molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

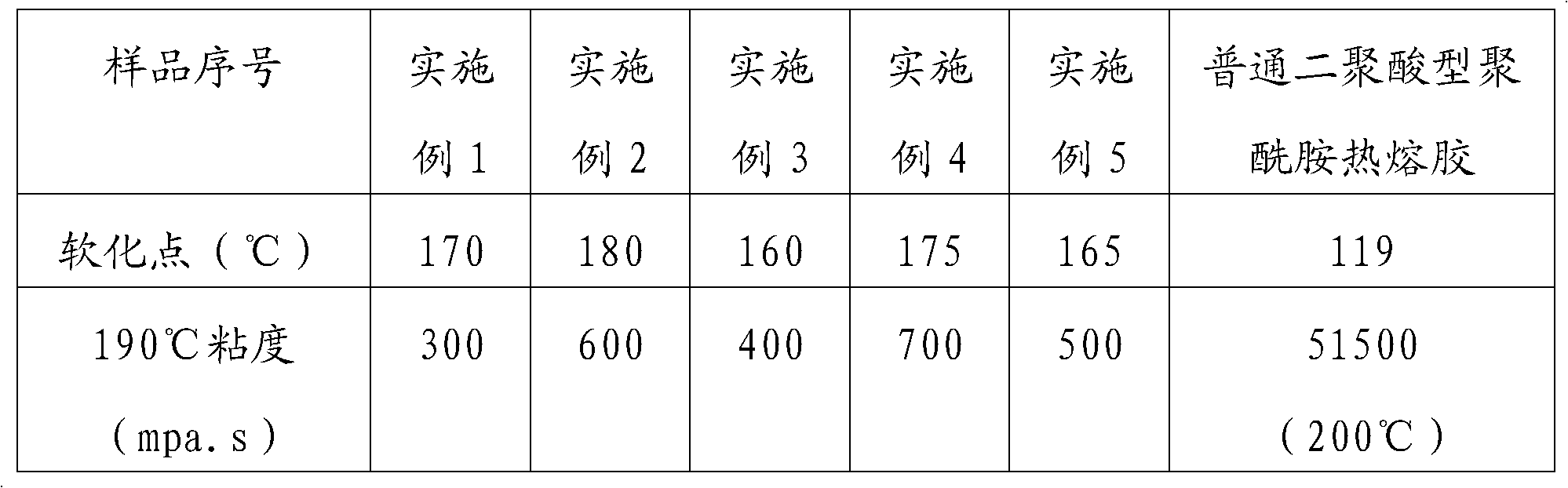

Examples

Embodiment 1

[0027] Add 190.00 g of hydrogenated dimer acid, 12.50 g of sebacic acid, 1.8 g of tetrakis[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl)propionic acid]pentaerythritol ester, and 19.82g ethylenediamine is packed in the constant pressure dropping funnel, feed into nitrogen and stir and start heating, the temperature is raised to 120 ℃ in 30 minutes, and at this temperature Start to slowly add ethylenediamine dropwise, and the dropwise addition is completed within 40 minutes. At this time, the temperature rises to 130°C, and forms a salt at this temperature for 2 hours, and then slowly raises the temperature. During this process, water will evaporate, 3 The temperature rose to 240°C within one hour, and was maintained at this temperature for 2 hours, then vacuumed with a vacuum pump for 2 hours to a pressure of 100 Pa, and finally discharged under the protection of nitrogen to obtain a light yellow rubber strip.

Embodiment 2

[0029] Add 193.10 g of dimer acid, 15.0 g of sebacic acid, 1.0 g of tetrakis[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl) propionic acid] pentaerythritol ester, 0.6g tris (2,4-di-tert-butylphenyl) phosphite, and 29.80g ethylenediamine is packed in the constant pressure dropping funnel, feed nitrogen Stir and start heating, raise the temperature to 120°C within 60 minutes, and slowly add ethylenediamine dropwise at this temperature, complete the dropwise addition within 60 minutes, then the temperature rises to 130°C, and form a salt at this temperature 2 Hours, and then slowly raise the temperature, during which water will evaporate, the temperature will rise to 280°C within 3 hours, keep at this temperature for 5 hours, then use a vacuum pump to evacuate for 3 hours to a pressure of 200Pa, and finally protect it under nitrogen Bottom discharge to obtain light yellow rubber strips.

Embodiment 3

[0031] Add 200.0g of dimer acid, 10.00g of sebacic acid, 1.5g of tetrakis[β-(3,5-di-tert-butyl-4 -Hydroxyphenyl) propionic acid] pentaerythritol ester, and 21.22g ethylenediamine is packed in the constant pressure dropping funnel, feed nitrogen and stir and start heating, the temperature is raised to 110 ℃ in 50 minutes, and at this temperature Start to slowly add ethylenediamine dropwise, and the dropwise addition will be completed within 70 minutes. At this time, the temperature will rise to 130°C, and salt will be formed at this temperature for 2 hours, and then the temperature will be raised slowly. During this process, water will evaporate, and it will take 2 hours The internal temperature was raised to 220°C, kept at this temperature for 1 hour, and then evacuated with a vacuum pump for 3 hours to a pressure of 400 Pa, and finally discharged under the protection of nitrogen to obtain a light yellow rubber strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com