Modified asphalt viscosity reducer and preparation method thereof

A technology of modified asphalt and viscosity reducer, which is applied in building components, building insulation materials, buildings, etc. It can solve the problems of aging of modified asphalt and achieve the effects of reducing high-temperature viscosity, increasing softening point and strength, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

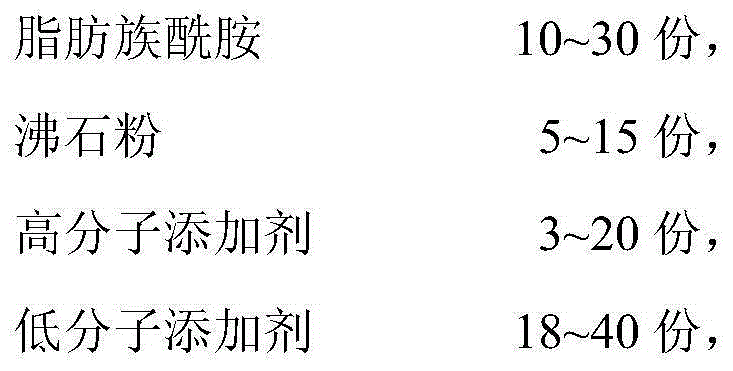

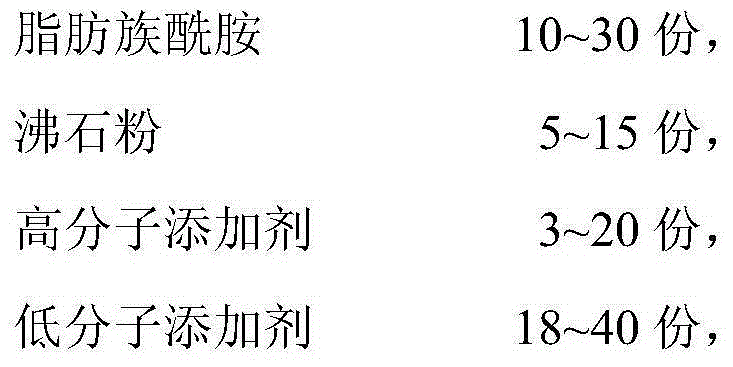

Method used

Image

Examples

Embodiment 1

[0012] 1000g of stearic acid amide, 1500g of zeolite powder, 300g of polypropylene oxide and 4000g of Tween 80 were respectively added to the reaction vessel, mixed at 60°C, and mechanically stirred for 30 minutes to prepare an asphalt viscosity reducer.

Embodiment 2

[0014] Add 3000g of stearic acid amide, 500g of zeolite powder, 2000g of phenolic resin, and 1800g of Span 80 into the reaction vessel respectively, mix at 100°C, and mechanically stir for 20 minutes to prepare an asphalt viscosity reducer.

Embodiment 3

[0016] Add 2000g of stearic acid amide, 1000g of zeolite powder, 1150g of polyvinyl alcohol, and 2900g of fatty alcohol polyoxyethylene ether into the reaction vessel respectively, mix at 80°C, and mechanically stir for 25 minutes to prepare an asphalt viscosity reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com