Transformer on-load voltage regulation construction method based on electrical smelting furnace for magnesium

A technology of an electric fused magnesia furnace and a construction method, which is applied in the directions of instruments, control/regulation systems, adaptive control, etc., can solve the problems of serious energy consumption and low automation level, and achieve the effect of good smelting and crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

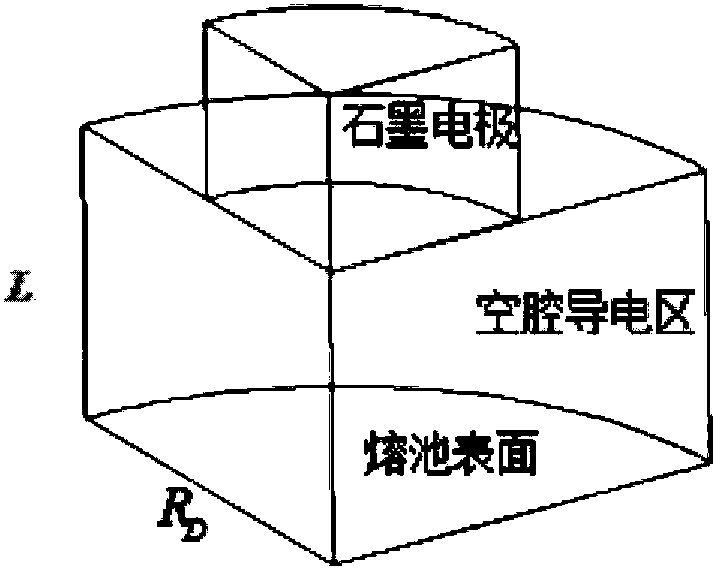

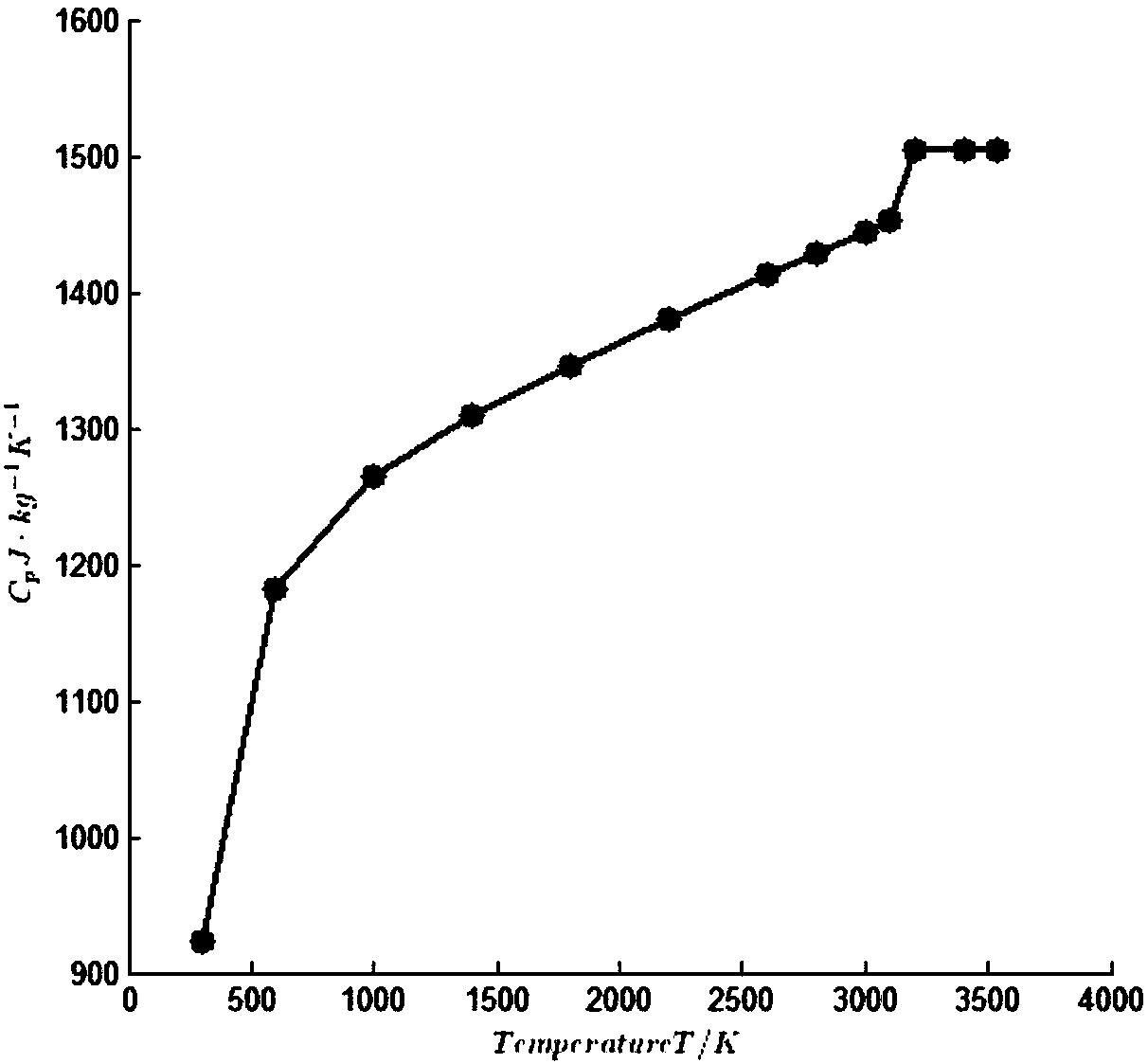

[0059] Aiming at the problem of high energy consumption of the electric fused magnesium furnace, the invention proposes an on-load voltage regulation design. Analyze the relationship between voltage, power and temperature. Under the premise of satisfying the melting power and temperature, analyze the heat transfer and resistance in the furnace to find the relationship between voltage and temperature, and finally solve the voltage value of each stage. Calculation of energy consumption and skin sand rate to verify the energy saving of the method.

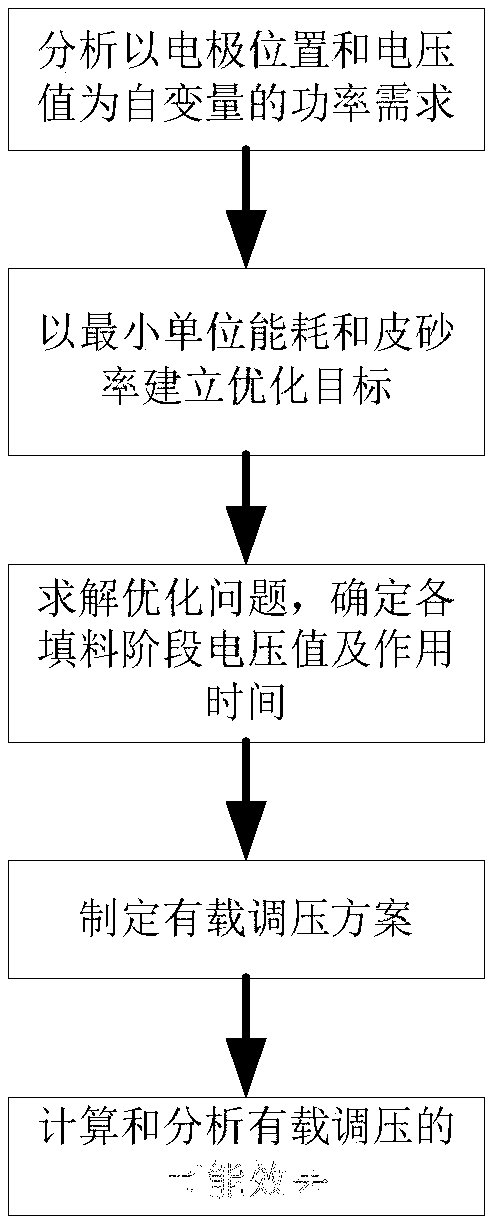

[0060] Such as figure 1 As shown, the present invention is based on the transformer on-load voltage regulation construction method of the fused magnesium furnace, comprising the following steps:

[0061] Analyze power demand with electrode position and voltage as independent variables;

[0062] According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com