Copper-contained waste metal copper recycling process

A technology for metal copper and copper waste, applied in the field of copper-containing waste metal copper recycling process, can solve the problems of not realizing the recycling of waste copper and the indeterminacy of copper alloy properties, and achieve the effects of reducing bonding strength, promoting separation, and promoting melting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

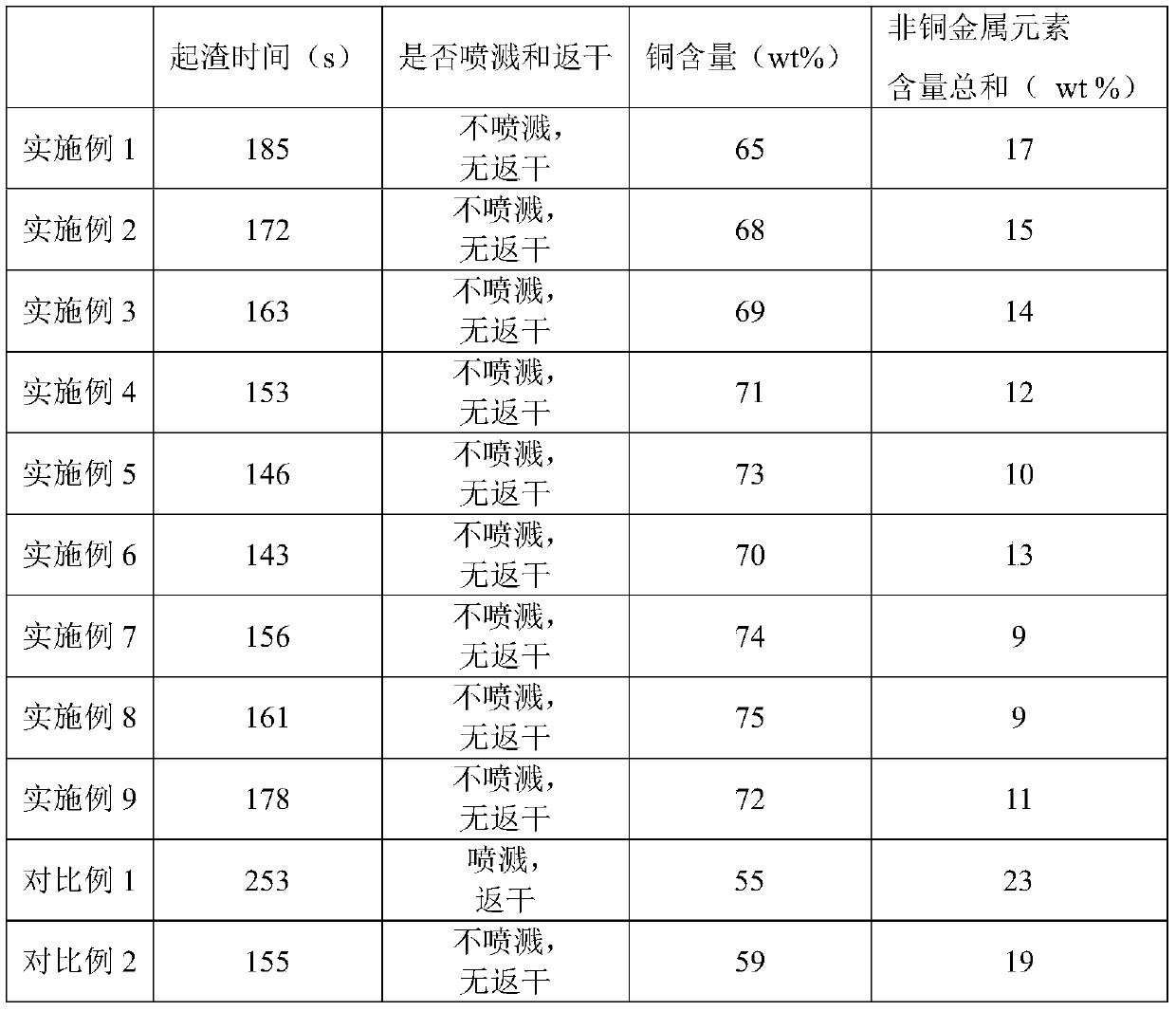

Embodiment 1

[0039] A kind of copper-containing scrap metal copper recovery process that embodiment 1 provides, comprises the following preparation steps:

[0040] Step 1, prepare copper-containing clinker:

[0041] All kinds of hazardous waste (except HW49) are transported to the warehouse in the hazardous waste area by airtight trucks, and are transported into the feed hopper of the rotary kiln through the feeder. A pusher and air lock facilities are installed under the feed hopper to ensure the negative pressure of the rotary kiln. run.

[0042] Hazardous waste in raw materials (including HW12 dye, paint waste, HW17 surface treatment, HW22 copper-containing waste, HW45 organic halide-containing waste, HW46 nickel-containing waste, HW48 non-ferrous metal smelting waste, HW50 waste catalyst, a total of 95000t / a) After batching until the copper content reaches 22wt%, it can enter the rotary kiln.

[0043] The incineration temperature in the rotary kiln is 850°C, using semi-coke as fuel, ...

Embodiment 2

[0055] A kind of copper-containing scrap metal copper recovery process that embodiment 2 provides, comprises the following preparation steps:

[0056] Step 1, preparing copper-containing clinker, the difference from Example 1 is that the burning time in the rotary kiln is 1.5h.

[0057] Step 2, preparation of copper-containing powder: the preparation method is the same as in Example 1.

[0058] Step 3, making bricks:

[0059] The difference from Example 1 is that tailing slag or refining slag is added to the copper-containing clinker and copper-containing powder.

[0060] Step 4, smelting:

[0061] The difference from Example 1 is that the addition of limestone is 0.8kg, the addition of quartz stone is 0.8kg, the addition of iron oxide powder is 0.8kg, the addition of semi-coke is 6kg, and the oxygen in the furnace air reaches 29vol%. , The melting temperature of the melting furnace is 1150°C.

[0062] Step 5, the treatment of flue gas from the smelting furnace is the same...

Embodiment 3

[0064] A kind of copper-containing scrap metal copper recovery process that embodiment 3 provides, comprises the following preparation steps:

[0065] Step 1, preparing copper-containing clinker, is the same as the preparation method of Example 1.

[0066] Step 2, preparation of copper-containing powder: the preparation method is the same as in Example 1.

[0067] Step 3, brick making: same as the preparation method of embodiment 1.

[0068] Step 4, smelting:

[0069] The difference from Example 1 is that the addition amount of limestone is 1kg, the addition amount of quartz stone is 1kg, the addition amount of iron oxide powder is 1kg, the addition amount of semi-coke is 7kg, the oxygen in the furnace air reaches 30vol%, the smelting furnace The melting temperature is 1200°C.

[0070] Step 5, the treatment of flue gas from the smelting furnace is the same as the treatment process in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com