Composite curing agent for lead-free preserved eggs and preparation method thereof

A technology of lead-free preserved eggs and pickling preparations, which is applied in the field of lead-free preserved egg compound pickling preparations and its preparation, and the additive field of lead-free preserved egg compound pickling preparations. It can solve the problems of long processing period of preserved eggs, unstable product quality, and There are black spots and other problems on the surface to achieve the effect of improving food safety and nutritional value, improving food safety, and good shell separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

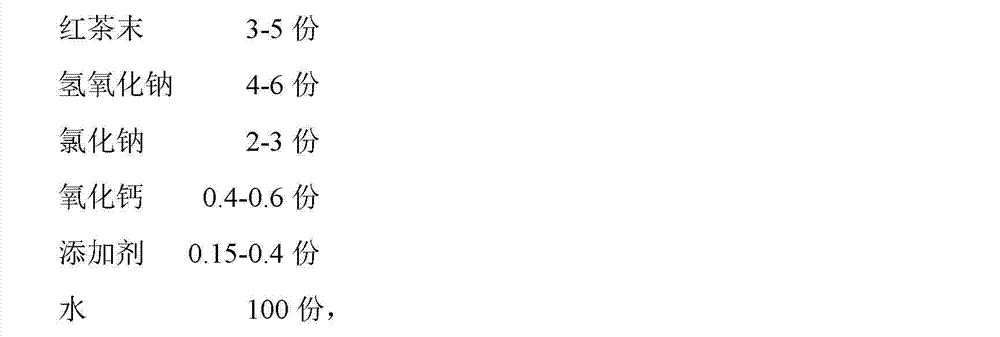

[0018] A kind of lead-free preserved egg compound salting preparation, is made from following raw material:

[0019]

[0020] The additive is prepared by mixing the following ingredients in parts by weight: 40 parts of zinc sulfate, 5 parts of copper sulfate, 45 parts of ferrous sulfate and 10 parts of zinc chloride.

[0021] The preparation method is as follows: adding black tea powder into water, boiling it slowly for 7 minutes, filtering it with gauze, and cooling the filtrate for later use; adding sodium hydroxide, sodium chloride, calcium oxide and additives into the above filtrate and stirring to dissolve.

[0022] Preserved egg pickling method: Wash and dry fresh duck eggs with uniform size and no cracks, add the above pickling agent, immerse the duck eggs in the pickling agent, cover the liquid surface with a plastic film and seal it, and cover the bucket; Put the above-mentioned plastic bucket in a constant temperature room at about 20°C, marinate for 22 days, then...

Embodiment 2

[0027] A kind of lead-free preserved egg compound salting preparation, is made from following raw material:

[0028]

[0029] The additive is prepared by mixing the following ingredients in parts by weight: 25 parts of zinc sulfate, 15 parts of copper sulfate, 40 parts of ferrous sulfate and 20 parts of zinc chloride.

[0030] The preparation method and preserved egg pickling method are the same as in Example 1.

[0031] The sensory quality evaluation method of preserved eggs and the assay method of copper, zinc and iron content are the same as in Example 1.

[0032] The eggshell of the preserved egg processed in this example has no spots, excellent shell-leaving performance, complete protein gel, good elasticity, tea brown, and pine flowers, and the egg yolk has three layers of color rings, with pine flowers on the surface, and has the unique flavor and taste of preserved eggs.

[0033] Measurement result shows, copper content reduces 29.3%, zinc content increases 10.4%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com