Method for preparing copper chloride hydroxide by simultaneously treating waste etching solution and circuit board sludge

A technology of simultaneous treatment of etching waste liquid, which is applied in the direction of copper chloride, copper halide, calcium/strontium/barium chloride, etc., can solve the problems of high process cost and low recovery degree, and achieve saving of alkali use and no three wastes Discharge, effect of saving acid use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

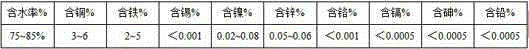

[0037] S1. Add 1800mL of water to 1000g circuit board sludge containing 3% copper and 75% water to make a slurry with a water content above 90%, stir for 3 hours, pass through a 600-mesh sieve, and activate;

[0038] S2. Aerate the mud activated by S1 for 2 hours with a Venturi tube, and divide it into two parts, 2000mL of aeration mud A and 500mL of aeration mud B;

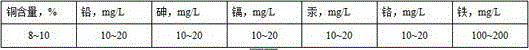

[0039] S3. Mix 1300mL of acidic etching waste liquid containing 8% copper and a density of 1.25g / ml with 65mL of 31% hydrochloric acid, then inject it into aeration mud A, adjust the pH to 0.5, and stir for 1 hour to obtain acid leaching mud C 3300mL;

[0040] S4. Slowly inject 340mL of aeration mud B into acid leaching mud C, adjust its pH to 2.5, stir for 1 hour, add 0.5mL of 0.1% polyacrylamide (cationic) solution, and suction filter to obtain the suction liquid phase and the solid phase; rinse the solid phase with tap water twice (550 mL each time), mix the rinse liquid with the suction filtrate, and absorb ...

Embodiment 2

[0045] S1. 1000g circuit board sludge containing 4.5% copper and 80% water content, add 2800mL water to make a slurry with a water content above 92.5%, stir for 2 hours, pass through a 500-mesh sieve, and activate;

[0046] S2. Use a Venturi tube to aerate the mud activated by S1 for 3.5 hours, and divide it into two parts, aeration mud A 3050mL, aeration mud B 650mL;

[0047] S3. Mix 1400mL of acidic etching waste liquid containing 9% copper and density of 1.3g / ml with 175mL of 31% hydrochloric acid, then inject it into the aeration mud A, adjust the pH to 1.5, and stir for 2 hours to obtain 4600mL of acid leaching mud C ;

[0048] S4. Slowly inject 640mL of aeration mud B into acid leaching mud C, adjust its pH to 2.8, stir for 2 hours, add 1mL of 0.08% polyacrylamide (anionic) solution, and suction filter to obtain the suction liquid phase and Solid phase; rinse the solid phase with tap water for 3 times (390mL each time), mix the rinse solution with the suction filtrate, ...

Embodiment 3

[0053] S1. 1000g circuit board sludge containing 6% copper and 85% water, add 4600mL water to make a slurry with a water content above 95%, stir for 1 hour, pass through a 400-mesh sieve, and activate;

[0054] S2. Use a Venturi tube to aerate the mud activated by S1 for 5 hours, and divide it into two parts, aeration mud A 4750mL, aeration mud B 850mL;

[0055] S3. Mix 1000mL of acidic etching waste liquid containing 10% copper and density of 1.35g / ml with 250mL of 31% hydrochloric acid, then inject into aeration mud A, adjust the pH to 2, and stir for 3 hours to obtain 6000mL of acid leaching mud C ;

[0056] S4. Slowly inject 850mL of aeration mud B into acid leaching mud C, adjust its pH to 3.2, stir for 3 hours, add 1.5mL of 0.05% polyacrylamide (non-ionic) solution, and suction filter to obtain the suction filtrate phase and solid phase; rinse the solid phase with tap water twice (300 mL each time), mix the rinse liquid with the suction filtrate, and absorb the COD in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com