Smelting method for high-manganese aluminum bronze alloy

A high-manganese-aluminum-bronze and alloy technology is applied in the smelting field of high-manganese-aluminum-bronze alloys, which can solve the problem that the content of alloy components cannot be accurately controlled, and achieve the effects of convenient smelting, reducing slag inclusion and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

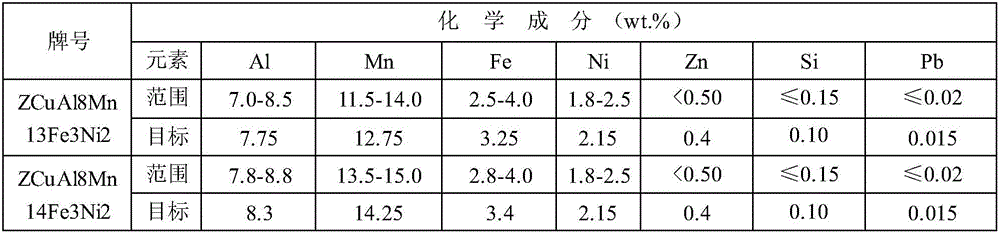

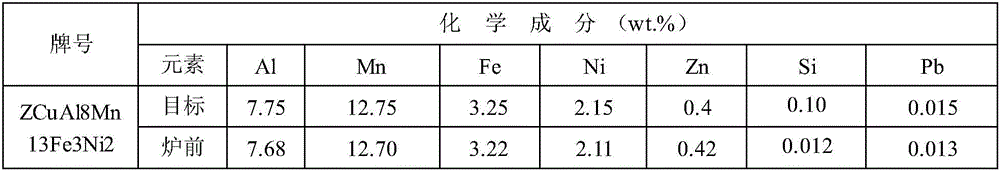

[0092] Melting of ZCuAl8Mn13Fe3Ni2 alloy:

[0093] Material preparation: Calculated by feeding 100kg, weigh 72.83kg of cathode copper, 8.15kg of high-purity aluminum, 13.08kg of electrolytic manganese, 3.25kg of high-purity iron, 2.16kg of electrolytic nickel, 0.417kg of industrial pure zinc, 0.015kg of pure lead and 0.100kg of crystalline silicon as raw material;

[0094] Clean the surface oxides of all metals to avoid foreign impurities from contaminating the molten metal; then dry the crystalline silicon and all metals in an oven to remove attached moisture and oil. During the drying process, the temperature of the oven is controlled 220°C; process high-melting-point alloy materials pure iron and pure nickel into shavings; clean up the residue of furnace materials in the furnace of the intermediate frequency induction furnace, and clean the furnace with cathode copper if necessary to avoid contamination of the melt by foreign substances; for the subsequent smelting process ...

Embodiment 2

[0107] Melting of ZCuAl8Mn13Fe3Ni2 alloy:

[0108] Material preparation: Calculated by feeding 100kg, weigh 72.83kg of cathode copper, 8.15kg of high-purity aluminum, 13.08kg of electrolytic manganese, 3.25kg of high-purity iron, 2.16kg of electrolytic nickel, 0.417kg of industrial pure zinc, 0.015kg of pure lead and 0.100kg of crystalline silicon as raw material;

[0109] Clean the surface oxides of all metals to avoid foreign impurities from contaminating the molten metal; then dry the crystalline silicon and all metals in an oven to remove attached moisture and oil. During the drying process, the temperature of the oven is controlled 230°C; process high-melting-point metal Fe and metal Ni into shavings; clean up the furnace material residue in the furnace of the intermediate frequency induction furnace, and clean the furnace with cathode copper if necessary to avoid contamination of the melt by foreign matter; for the subsequent smelting process The sample spoon, graphite ...

Embodiment 3

[0121] Melting of ZCuAl8Mn14Fe3Ni2 alloy:

[0122] Material preparation: Calculated by feeding 100kg, weigh 70.55kg of cathode copper, 8.73kg of high-purity aluminum, 14.62kg of electrolytic manganese, 3.399kg of high-purity iron, 2.162kg of electrolytic nickel, 0.417kg of industrial pure zinc, 0.015kg of pure lead and 0.100kg of crystalline silicon as raw material;

[0123] Clean the surface oxides of all metals to avoid foreign impurities from contaminating the molten metal; then dry the crystalline silicon and all metals in an oven to remove attached moisture and oil. During the drying process, the temperature of the oven is controlled 210°C; process high melting point metal Fe and metal Ni into shavings; clean up the furnace material residue in the intermediate frequency induction furnace, and if necessary, use cathode copper to clean the furnace to avoid contamination of the melt by foreign matter; for subsequent smelting process The sample spoon, graphite stirring rod a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com