Burner of reverberatory furnace

A reverberatory furnace and injection head technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of low fuel utilization rate, affecting the service life of the furnace vault, uneven furnace temperature, etc., and achieve wide flame coverage , Improve fuel utilization rate, ideal effect of flame shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

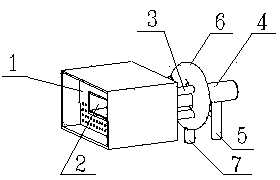

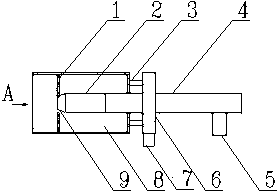

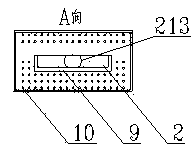

[0025] Such as Figure 1~8 As shown, a reverberatory furnace burner includes a natural gas main pipe 4, and the front end of the natural gas main pipe 4 is connected with a spouting head 2 with a necking. The spouting head 2 with a necking includes a nozzle body 21 and a necking 22. The head body 21 has a hollow axisymmetric quadrangular pyramid structure. The quadrangular pyramid A end surface 212 is fully open, and the B end surface 211 is provided with a connecting port 213 connected to the front end of the natural gas main pipe 4. The end face 212 of the head body A is fixedly connected, and the ejection head body 21 and the necking 22 are an integral structure; the nozzle with a necking 2 is located in the oxygen distribution chamber 8;

[0026] The oxygen distribution chamber 8 is a closed cavity connected to the furnace, so that oxygen can enter the oxygen distribution chamber 8 more evenly. The rear end of the oxygen distribution chamber 8 is connected with an oxygen ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com